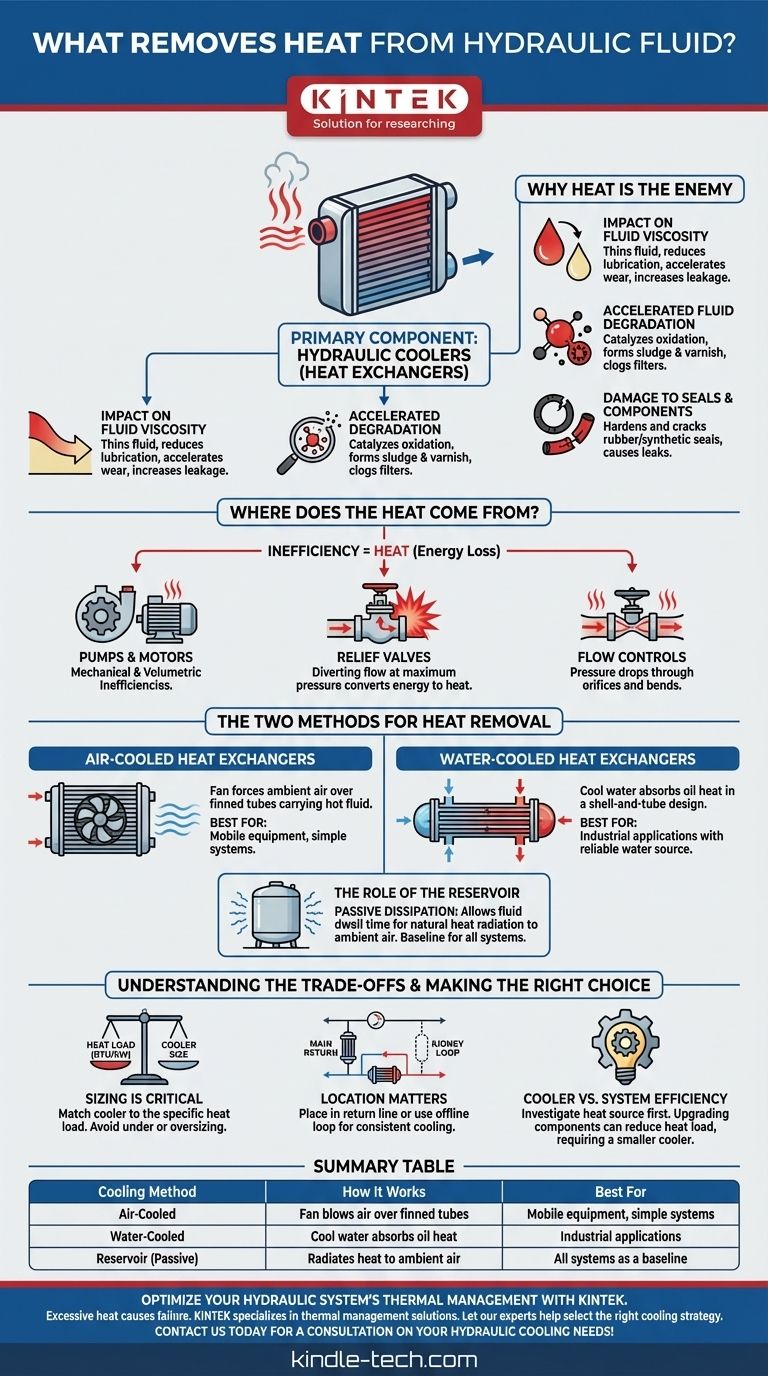

The primary components that remove heat from hydraulic fluid are hydraulic coolers, which are a type of heat exchanger. They work by transferring thermal energy from the hot hydraulic oil to a cooler medium, which is most often ambient air or water. While a system's reservoir and plumbing also radiate some heat, a dedicated cooler is the definitive solution for managing significant heat loads.

While a hydraulic cooler is the component that removes heat, the core issue is that excess heat is a direct symptom of system inefficiency. Truly effective thermal management involves both selecting the right cooler and understanding how to minimize the heat being generated in the first place.

Why Heat is the Primary Enemy of Hydraulic Systems

Excessive heat is not merely an operational concern; it is the leading cause of component failure and system unreliability. Understanding the consequences of uncontrolled heat is critical for maintaining a healthy hydraulic system.

The Impact on Fluid Viscosity

Hydraulic oil thins as it gets hotter, reducing its viscosity. This thinner fluid fails to provide an adequate lubricating film between moving parts, accelerating wear. It also increases internal leakage within pumps, motors, and valves, which reduces system efficiency and generates even more heat.

Accelerated Fluid Degradation

Heat acts as a catalyst for the oxidation of hydraulic fluid. This process breaks down the oil, forming sludge, varnish, and corrosive acids. These contaminants clog filters, stick valves, and attack system components, drastically shortening the life of both the fluid and the hardware.

Damage to Seals and Components

Seals, gaskets, and hoses are typically made from rubber or synthetic compounds that are highly susceptible to heat. High temperatures cause them to harden, crack, and lose their sealing ability, leading to both internal and external leaks.

Where Does the Heat Come From?

Heat is a byproduct of energy loss. In a perfect system, all input power would be converted into useful work. In reality, every inefficiency in a hydraulic circuit generates heat.

Inefficiency is the Source

The fundamental source of heat is any pressure drop that does not perform work. When fluid is forced through an orifice, flows over a relief valve, or experiences friction against pipe walls, the energy lost in that process is converted directly into heat.

Key Culprits in the System

The most significant heat generators are typically:

- Pumps and Motors: Mechanical and volumetric inefficiencies mean not all input power becomes fluid power, with the loss radiating as heat.

- Relief Valves: When a relief valve opens to divert flow at maximum pressure, nearly all the energy is converted into intense heat.

- Flow Controls: Throttling valves, and even sharp bends in plumbing, create pressure drops that generate heat.

The Two Methods for Heat Removal

Once generated, heat is removed through passive dissipation and active cooling. While all systems benefit from passive dissipation, most require an active cooling solution.

Air-Cooled Heat Exchangers

These are the most common type of cooler. They function like a car's radiator, where hot hydraulic fluid flows through a series of tubes covered in fins. A fan, either electric or hydraulically driven, forces ambient air across the fins to carry the heat away. They are simple, cost-effective, and ideal for mobile equipment.

Water-Cooled Heat Exchangers

These coolers are more compact and offer higher thermal efficiency. In a shell-and-tube design, hydraulic oil flows through the "shell" while cool water flows through a bundle of tubes inside it. The heat transfers from the oil to the water, which is then discharged. They are common in industrial settings where a reliable water source is available.

The Role of the Reservoir

The hydraulic reservoir itself is the first line of defense. A sufficiently large tank provides time for the fluid to dwell, allowing heat to naturally radiate from the tank's surface area into the surrounding air. Proper reservoir design is a critical aspect of passive thermal management.

Understanding the Trade-offs

Simply adding a cooler is not always the best solution. A properly engineered system considers the entire thermal load and operational context.

Sizing is Critical

A cooler must be sized based on the system's heat load—the amount of energy (in BTU or kW) that needs to be removed. An undersized cooler will fail to keep the fluid at the target temperature. An oversized cooler is an unnecessary expense in terms of initial cost, space, and potentially energy consumption.

Location Matters

The placement of the cooler in the circuit is important. The most common location is in the main return line before the fluid enters the reservoir. For sensitive components or high-heat circuits, a separate offline "kidney loop" with its own pump and cooler can provide more consistent and controlled cooling.

Cooler vs. System Efficiency

Before investing in a larger cooler, always investigate the source of the heat. Sometimes, upgrading to a more efficient variable-displacement pump or redesigning a circuit to minimize pressure drops can reduce the heat load so much that a smaller cooler—or none at all—is required. Treating the cause is always better than treating the symptom.

Making the Right Choice for Your System

Selecting a cooling strategy depends on your application, environment, and performance goals.

- If your primary focus is mobile equipment or simplicity: An air-cooled heat exchanger is the most practical and common choice.

- If your primary focus is high-power industrial applications with a water source: A water-cooled exchanger offers superior, compact, and consistent cooling performance.

- If your primary focus is overall system health and longevity: First, analyze the system to minimize heat generation through efficient design, then size a cooler to handle the remaining heat load.

Ultimately, managing hydraulic heat is a function of both efficient removal and intelligent system design.

Summary Table:

| Cooling Method | How It Works | Best For |

|---|---|---|

| Air-Cooled Heat Exchanger | Fan blows air over finned tubes carrying hot fluid | Mobile equipment, simple systems |

| Water-Cooled Heat Exchanger | Cool water flows through tubes to absorb oil heat | Industrial applications with water access |

| Reservoir (Passive) | Fluid dwells in tank, radiating heat to ambient air | All systems as a baseline |

Optimize your hydraulic system's thermal management with KINTEK.

Excessive heat is the primary cause of hydraulic component failure and fluid degradation. KINTEK specializes in lab equipment and consumables, including thermal management solutions for testing and industrial applications. Our experts can help you select the right cooling strategy to protect your investment, improve efficiency, and extend equipment life.

Contact us today for a consultation on your hydraulic cooling needs!

Visual Guide

Related Products

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Hexagonal Boron Nitride HBN Thermocouple Protection Tube

People Also Ask

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What are the potential hazards in a hydraulic press? Understanding the Risks of Crushing, Injection, and Failure

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law