Operating a press machine safely is a matter of strict procedural discipline and constant situational awareness. Fundamentally, safety relies on ensuring only qualified personnel handle the machine, performing rigorous pre-operation checks, immediately stopping work at any sign of malfunction like unusual noise or leaks, and following correct shutdown procedures after every use. These protocols are not optional; they are the primary defense against equipment failure and severe injury.

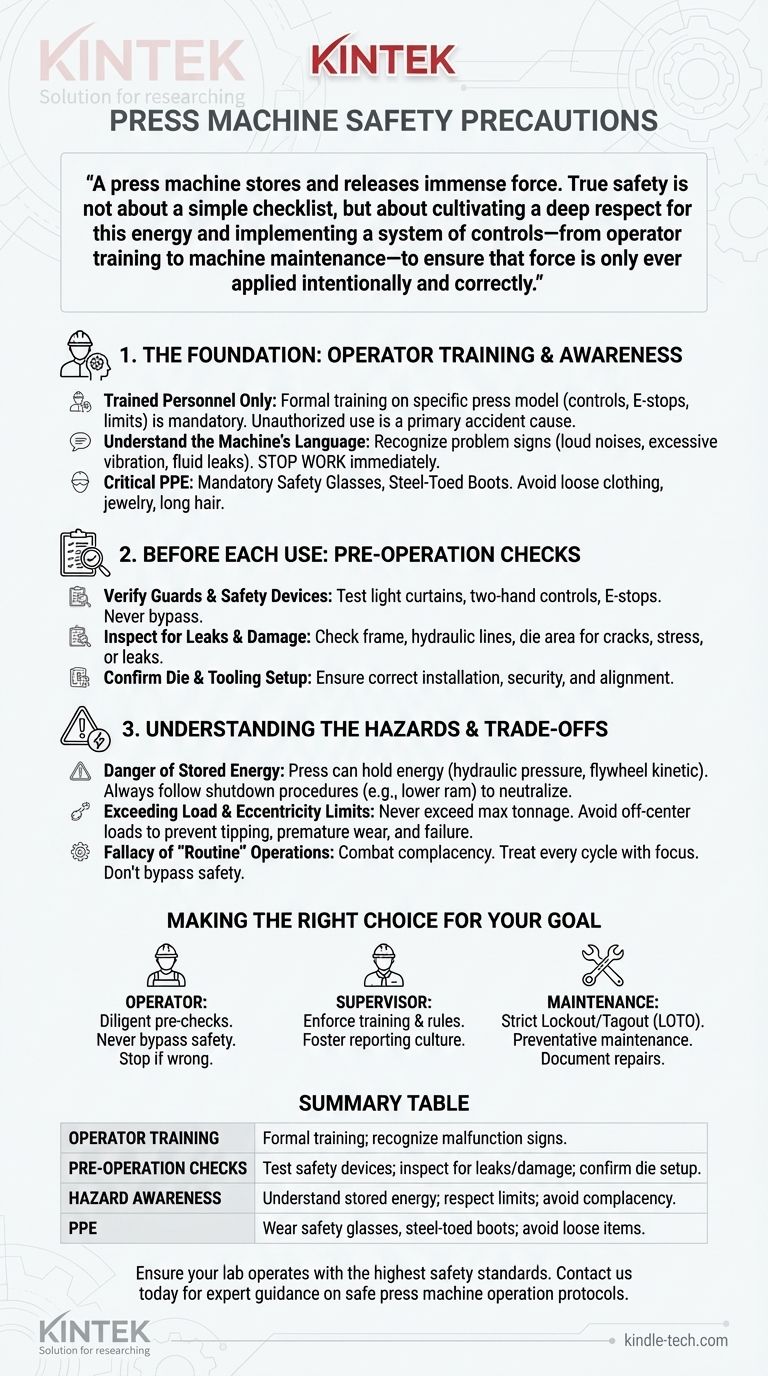

A press machine stores and releases immense force. True safety is not about a simple checklist, but about cultivating a deep respect for this energy and implementing a system of controls—from operator training to machine maintenance—to ensure that force is only ever applied intentionally and correctly.

The Foundation: Operator Training and Awareness

The single most important safety device for any machine is a well-trained and alert operator. Technology and guards can fail, but a knowledgeable operator who understands the risks is the last and most critical line of defense.

Why "Trained Personnel Only" is Non-Negotiable

Only operators who have received formal training on a specific press model should ever use it. This training must cover its unique controls, emergency stop mechanisms, capacity limits, and specific safety features. Unauthorized operation is a primary cause of catastrophic accidents.

Understanding the Machine's Language

A press communicates its health through sound, vibration, and visual cues. An operator must be trained to recognize the signs of a problem. Loud or unusual noises, excessive vibration, or any fluid leakage (like hydraulic oil) are signals to stop work immediately. These symptoms can indicate imminent mechanical failure.

The Critical Role of Personal Protective Equipment (PPE)

Appropriate PPE is mandatory when working with or near a press. At a minimum, this includes safety glasses with side shields and steel-toed boots. Depending on the specific operation and material, additional gear like gloves or hearing protection may be required. Loose clothing, jewelry, or untied long hair should never be worn, as they can be caught in moving parts.

Before Each Use: Pre-Operation Safety Checks

Most incidents are preventable, and many potential failures can be identified before the machine is ever started. A consistent pre-operation inspection is a non-negotiable part of the workflow.

Verifying Guards and Safety Devices

All physical guards must be in place and secure. Safety devices like light curtains, two-hand controls, and emergency stop buttons must be tested to ensure they are functioning perfectly before any production begins. Never operate a press with a bypassed or malfunctioning safety device.

Inspecting for Leaks and Structural Damage

Visually inspect the machine frame, hydraulic lines, and die area. Look for any signs of cracks, stress, or fluid leaks. A small leak can be an early indicator of a future hose rupture or seal failure, which can result in a sudden loss of pressure and control.

Confirming Die and Tooling Setup

Ensure the die set is correctly installed, secured, and aligned. Improperly seated tooling can shift during operation, leading to damage to the press, ruined parts, and a significant safety hazard for the operator.

Understanding the Hazards and Trade-offs

Recognizing the inherent dangers of a press machine is key to respecting its power and avoiding complacency. The primary risks come from the immense force the machine generates and the potential for that energy to be released unexpectedly.

The Danger of Stored Energy

Even when not in motion, a press can hold stored energy. A hydraulic press can maintain pressure, and a mechanical press's flywheel stores kinetic energy. This is why procedures like lowering the slider or ram to its lowest position after use are critical. It mechanically releases or neutralizes the stored energy, preventing an accidental or unintended stroke.

Exceeding Load and Eccentricity Limits

Every press has a maximum tonnage rating that must never be exceeded. Just as critical is the eccentricity limit, which refers to how far off-center the load can be applied. Applying a load far from the center of the ram creates a powerful tipping or bending force on the machine's components, which can lead to premature wear and catastrophic failure. Think of it like trying to push a tall filing cabinet from the very top corner instead of its center—it's much more likely to twist and become unstable.

The Fallacy of "Routine" Operations

Complacency is one of the greatest dangers. After hundreds of successful cycles, an operator may begin to see the work as routine and take shortcuts. This mindset leads to bypassing safety features or placing hands in unsafe areas. Every machine cycle must be treated with the same level of focus and respect as the first.

Making the Right Choice for Your Goal

Implementing a culture of safety requires a commitment from everyone who interacts with the machine, from the operator to the maintenance team.

- If your primary focus is operating the press: Your responsibility is to perform pre-operation checks diligently, never bypass a safety device, and stop work immediately if anything seems wrong.

- If your primary focus is supervising a work area: Your responsibility is to ensure operators are formally trained, enforce all safety rules without exception, and foster an environment where reporting problems is encouraged.

- If your primary focus is maintaining the equipment: Your responsibility is to implement a strict lockout/tagout (LOTO) procedure before any service, conduct preventative maintenance, and document all repairs thoroughly.

Ultimately, safety is not a static goal but a continuous process of training, inspection, and vigilance.

Summary Table:

| Safety Precaution Category | Key Actions |

|---|---|

| Operator Training | Formal training for specific press models; recognize signs of malfunction. |

| Pre-Operation Checks | Test safety devices (light curtains, E-stops); inspect for leaks/damage; confirm die setup. |

| Hazard Awareness | Understand stored energy; never exceed load/eccentricity limits; avoid complacency. |

| Personal Protective Equipment (PPE) | Wear safety glasses, steel-toed boots; avoid loose clothing/jewelry. |

Ensure your lab operates with the highest safety standards. Properly maintained and safely operated equipment is the foundation of productive and secure laboratory work. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the right press machine and provide guidance on safe operation protocols. Contact us today to discuss your requirements and create a safer, more efficient lab environment.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation