The micron rating of a filter press is not determined by the press itself, but by the filter cloth installed within it. These cloths are interchangeable and available in a vast range of micron ratings, from over 100 for coarse materials down to 1 micron or even sub-micron levels for fine chemical and pharmaceutical applications. Therefore, there is no single micron size for a filter press.

A filter press is a system. The mechanical press provides the pressure, but the filter cloth dictates the particle separation size (micron rating). Selecting the right cloth, not the right press, is the most critical decision for achieving your desired filtration outcome.

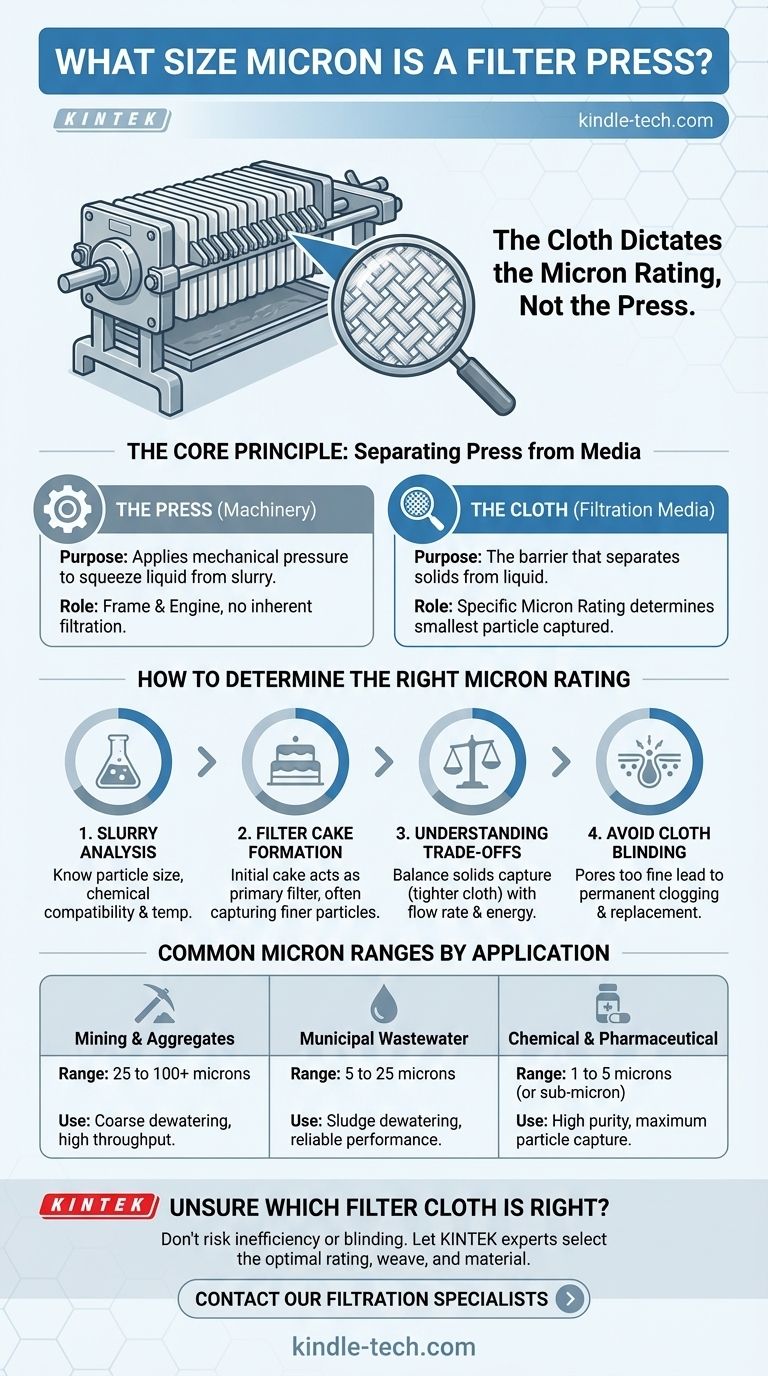

The Core Principle: Separating the Press from the Media

To properly select a filtration solution, you must understand the distinct roles of the mechanical press and the filter media. Confusing the two is a common and costly mistake.

The Role of the Filter Press

A filter press is a piece of heavy machinery designed for one primary purpose: to apply mechanical pressure. Its job is to squeeze the liquid out of a slurry that has been pumped into its chambers.

The press itself—whether it's an overhead beam, sidebar, or manual model—has no inherent filtration capability. Think of it as the frame and the engine, but not the tool that does the work.

The Role of the Filter Cloth

The filter cloth is the actual filtration medium. It is a woven or felted fabric sheet that lines the filter plates inside the press. This cloth is the barrier that separates the solid particles from the liquid.

Each cloth has a specific micron rating, which is a nominal measure of the size of the pores in the fabric. This rating determines the smallest particle the cloth is designed to capture.

Why They Are Separate Components

The press and the cloth are separate for versatility and maintenance. A single filter press can be used for dozens of different applications simply by changing the filter cloth.

Cloths are also consumable items that wear out over time. Keeping them separate from the capital equipment of the press makes replacement practical and cost-effective.

How to Determine the Right Micron Rating

Choosing the correct micron rating is a technical decision that directly impacts efficiency, product quality, and operational cost. It's a balance between several competing factors.

It Starts with Your Slurry

The most important factor is the nature of the material you are filtering, known as the slurry. You need to know the particle size distribution. A lab analysis of your slurry is the most reliable starting point.

Chemical compatibility and temperature are also critical. The cloth material (e.g., polypropylene, polyester, nylon) must be able to withstand the chemical environment and operating temperatures without degrading.

The Importance of the Filter Cake

Here is a critical concept: the filter cloth's initial job is to start building a filter cake. As the first layer of solids deposits on the cloth, this cake itself becomes the primary filter medium.

This filter cake is often much more efficient at capturing fine particles than the cloth alone. A 20-micron cloth might end up capturing particles down to 5 microns once a stable cake has formed. This phenomenon is why you often don't need a cloth with a micron rating equal to your smallest particle.

Common Micron Ranges by Application

While every application is unique, general ranges can provide a starting point:

- Mining & Aggregates: Often require coarser filtration for dewatering tailings. Common ratings are 25 to 100+ microns.

- Municipal Wastewater: Sludge dewatering typically uses cloths in the 5 to 25 micron range.

- Chemical & Pharmaceutical: Require very high purity. Ratings are often 1 to 5 microns, and sometimes sub-micron, to ensure maximum particle capture.

Understanding the Trade-offs

Selecting a micron rating is not about finding the smallest number. It's about finding the optimal balance for your specific process.

The Myth of the "Perfect" Rating

A lower micron rating is not always better. While a "tighter" cloth captures more solids, it also reduces the flow rate (throughput) and increases the back pressure required.

This can dramatically slow down your cycle times and increase energy consumption, making the process inefficient.

Cloth Blinding and Maintenance

If the filter cloth's pores are too fine for the application, they can become permanently clogged, a phenomenon known as blinding.

A blinded cloth cannot be cleaned effectively and must be replaced. This leads to significant downtime and increased operational costs. It is often better to use a slightly larger micron rating and rely on the filter cake to do the fine filtering.

Material and Weave Matter, Too

Micron rating is just one specification. The weave pattern (e.g., monofilament, multifilament, sateen) affects the cloth's particle release properties (cake discharge) and its resistance to blinding. The material itself dictates chemical and thermal resistance.

Making the Right Choice for Your Application

Your selection should be guided by a clear understanding of your operational priorities.

- If your primary focus is maximizing solids capture: Start with a lower micron rating and plan for a pilot test to assess cake formation and the potential for blinding.

- If your primary focus is high throughput (flow rate): Opt for the largest micron rating that still produces an acceptably clear filtrate and a stable, easily discharged filter cake.

- If you are dealing with a new or unknown slurry: Always conduct a lab analysis or pilot test with different cloths before making a large-scale investment.

Ultimately, viewing the filter press as a system—with the cloth as its most critical variable—is the key to successful solid-liquid separation.

Summary Table:

| Application | Typical Micron Range | Key Considerations |

|---|---|---|

| Mining & Aggregates | 25 to 100+ microns | Coarse dewatering, high throughput |

| Municipal Wastewater | 5 to 25 microns | Sludge dewatering, reliable performance |

| Chemical & Pharmaceutical | 1 to 5 microns (or sub-micron) | High purity, maximum particle capture |

Unsure which filter cloth is right for your slurry? Don't risk inefficiency or cloth blinding. The experts at KINTEK can help you select the optimal micron rating, weave, and material for your specific lab equipment and consumables needs.

Contact our filtration specialists today for a consultation and ensure your solid-liquid separation process is a success.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What are some of the problems related to hydraulic power? Manage Leaks, Contamination, and Inefficiency

- What are the preventive maintenance of hydraulic systems? Extend Equipment Life and Maximize Uptime

- What happens if a hydraulic system leaks? Prevent Costly Damage and Safety Hazards

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration