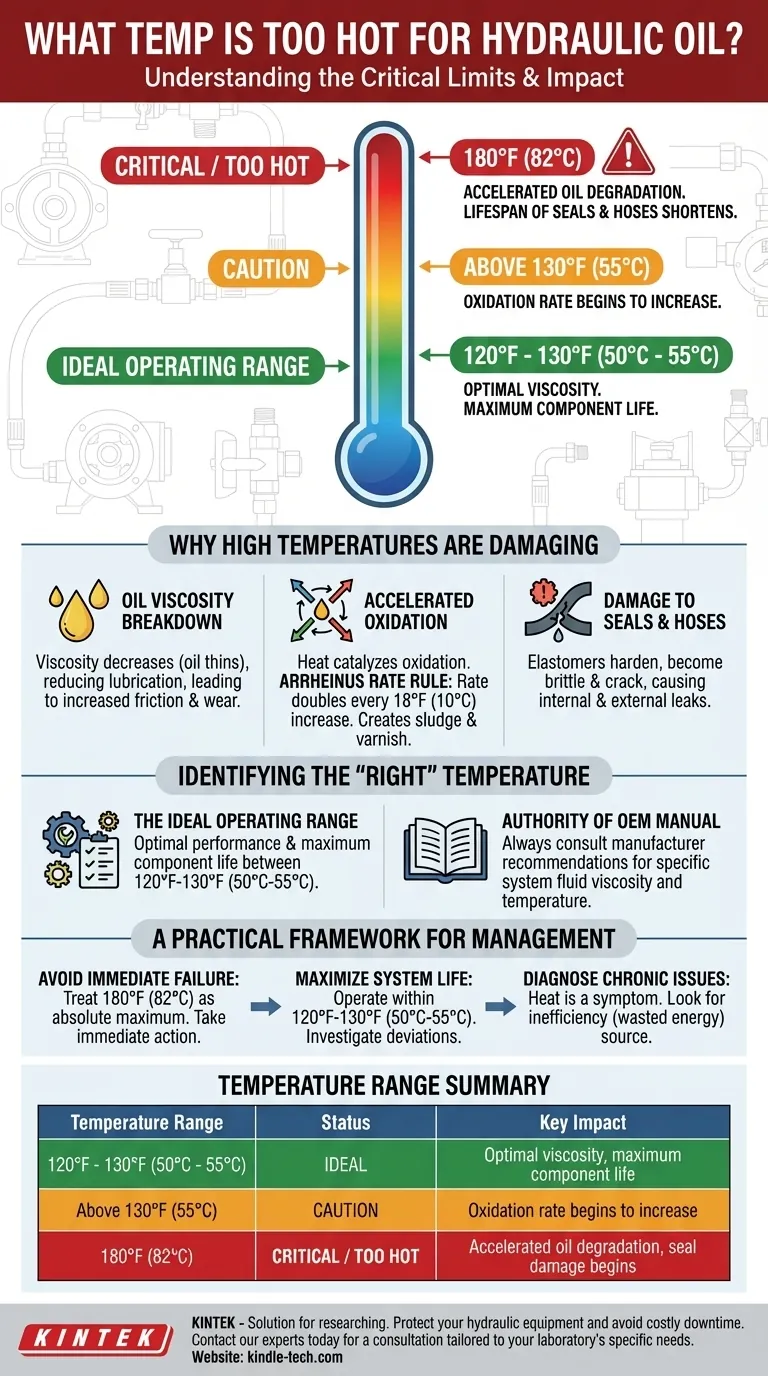

As a general rule, hydraulic oil temperature becomes critical and potentially damaging above 180°F (82°C). At this point, the rate of oil degradation accelerates significantly, and the lifespan of seals and hoses begins to shorten. However, this number is a ceiling, not a target.

The core issue isn't a single "too hot" number, but rather the fundamental relationship between heat, oil viscosity, and the rate of chemical breakdown. Every degree above the optimal range reduces the life of your oil and the reliability of your system.

Why High Temperatures Are So Damaging

Heat is the primary enemy of a hydraulic system. It doesn't just make things hot; it actively degrades the components and the fluid that serves as the system's lifeblood.

Oil Viscosity Breakdown

Hydraulic oil's most important property is its viscosity, or its resistance to flow. The system is designed to operate with a specific viscosity to create a strong lubricating film between moving parts.

As temperature increases, viscosity decreases—the oil becomes thinner. This thinning reduces the oil's ability to lubricate, leading to increased metal-to-metal contact, friction, and wear.

Accelerated Oxidation

Heat acts as a catalyst for oxidation, a chemical reaction between the oil and oxygen. This process is the primary cause of oil aging.

A well-established principle, the Arrhenius Rate Rule, states that for every 18°F (10°C) increase in temperature, the rate of oxidation doubles. This means oil that might last 2000 hours at 140°F (60°C) may only last 500 hours at 176°F (80°C).

Oxidation creates byproducts like sludge and varnish, which can clog filters, stick valves, and coat internal surfaces, further impeding heat dissipation.

Damage to Seals and Hoses

The seals, O-rings, and hoses in a hydraulic system are typically made from elastomers. Prolonged exposure to high temperatures causes these materials to harden, become brittle, and crack.

This leads to both internal and external leaks, reducing system pressure, causing fluid loss, and creating safety hazards.

Identifying the "Right" Temperature for Your System

While 180°F (82°C) is the upper limit, it is far from ideal. Optimal performance and maximum component life are achieved in a much narrower, cooler range.

The Ideal Operating Range

Most hydraulic systems are designed to operate most efficiently with an oil temperature between 120°F and 130°F (50°C to 55°C).

Operating within this range maintains the oil's ideal viscosity, minimizes the rate of degradation, and ensures the longevity of all system components.

The Authority of the OEM Manual

The most definitive source for your equipment's temperature limits is the Original Equipment Manufacturer (OEM).

The manufacturer has specified the components and engineered the system to work with a fluid of a certain viscosity. Always consult the service manual for specific temperature recommendations.

Understanding the Trade-offs and Common Causes

Managing temperature is about balancing performance and longevity. Ignoring high heat introduces significant operational and financial risks.

The True Cost of Overheating

Running a system too hot is a costly decision. The consequences include increased component wear, unplanned downtime for repairs, higher fluid consumption due to accelerated aging, and reduced machine efficiency.

Common Culprits of Excess Heat

Heat is a symptom, not the root cause. If your system is running hot, the cause is often one of the following:

- Internal Leakage: Worn pumps, motors, or valves leaking internally.

- System Inefficiency: Incorrect pressure settings or flow restrictions.

- Inadequate Cooling: Clogged or undersized heat exchangers (radiators).

- Low Reservoir Fluid Level: Not enough oil to properly rest and cool.

A Practical Framework for Temperature Management

Your approach to hydraulic temperature should be proactive, not reactive. Use these guidelines to make an informed decision based on your operational priorities.

- If your primary focus is avoiding immediate failure: Treat 180°F (82°C) as your absolute maximum and take immediate corrective action if temperatures exceed it.

- If your primary focus is maximum system life and reliability: Operate within the optimal range of 120°F to 130°F (50°C to 55°C) and investigate any sustained deviation.

- If you are diagnosing a chronic overheating problem: Remember that heat is generated by wasted energy, so look for the source of the inefficiency rather than just trying to cool the oil.

Ultimately, proactive temperature management is the single most effective strategy for ensuring the long-term health and reliability of your hydraulic system.

Summary Table:

| Temperature Range | Status | Key Impact |

|---|---|---|

| 120°F - 130°F (50°C - 55°C) | Ideal | Optimal viscosity, maximum component life |

| Above 130°F (55°C) | Caution | Oxidation rate begins to increase |

| 180°F (82°C) | Critical / Too Hot | Accelerated oil degradation, seal damage begins |

Protect your hydraulic equipment and avoid costly downtime. KINTEK specializes in lab equipment and consumables, including solutions for monitoring and maintaining optimal fluid conditions. Our expertise can help you ensure the reliability and longevity of your systems. Contact our experts today for a consultation tailored to your laboratory's specific needs.

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing