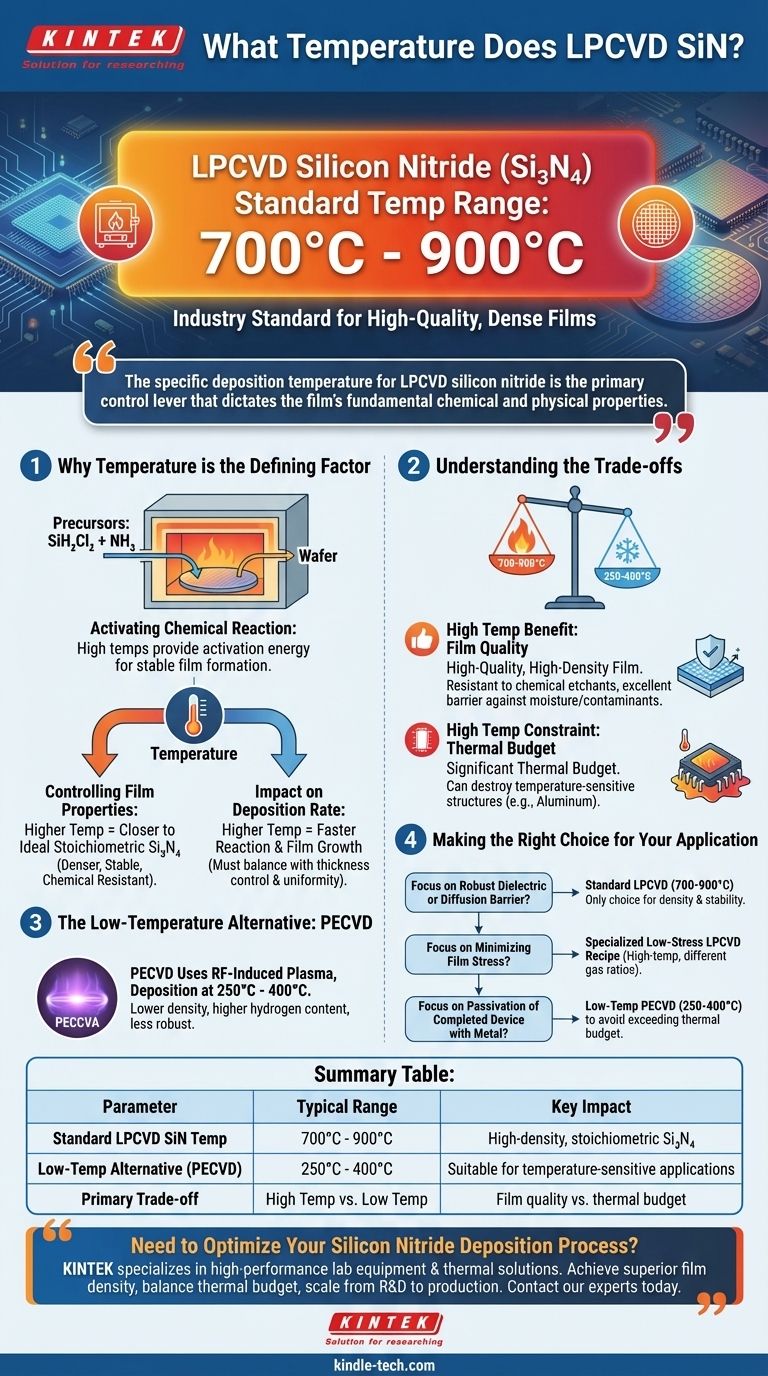

In the context of semiconductor manufacturing, Low-Pressure Chemical Vapor Deposition (LPCVD) of standard, stoichiometric silicon nitride (Si₃N₄) is typically performed at a high-temperature range of 700°C to 900°C. While some specialized processes or alternative materials exist at different temperatures, this range is the industry standard for creating the high-quality, dense films required for most electronic applications.

The specific deposition temperature for LPCVD silicon nitride is not just a process setting; it is the primary control lever that dictates the film's fundamental chemical and physical properties, including its density, stress, and chemical resistance.

Why Temperature is the Defining Factor in LPCVD SiN

The success of LPCVD hinges on providing enough thermal energy to drive a specific chemical reaction on the wafer's surface. For silicon nitride, this process is precise and highly temperature-dependent.

Activating the Chemical Reaction

LPCVD silicon nitride is most commonly formed from the reaction of dichlorosilane (SiH₂Cl₂) and ammonia (NH₃). The high temperatures inside the furnace provide the activation energy needed to break the chemical bonds of these precursor gases, allowing silicon and nitrogen atoms to deposit and form a solid, stable film on the substrate.

Without sufficient heat, this reaction would not proceed efficiently, resulting in poor or non-existent film growth.

Controlling Film Properties

The temperature directly influences the final characteristics of the film. Higher temperatures generally yield a film that is closer to the ideal stoichiometric Si₃N₄ ratio.

This results in a denser, more stable film with superior properties, such as a lower wet etch rate and better performance as an electrical insulator or a diffusion barrier.

Impact on Deposition Rate and Uniformity

While pressure is the main factor for uniformity across a wafer (the "LP" in LPCVD), temperature governs the deposition rate. Within the operational window, a higher temperature increases the rate of reaction and thus the speed at which the film grows.

Process engineers must balance this rate against the need for precise thickness control and film quality.

Understanding the Trade-offs

Choosing a deposition temperature involves a critical trade-off between achieving the highest possible film quality and respecting the thermal limitations of the device being fabricated.

The Benefit of High Temperature: Film Quality

The 700°C to 900°C range is used because it produces a high-quality, high-density film. This film is very resistant to chemical etchants and serves as an excellent barrier against the diffusion of moisture or other contaminants, which is critical for protecting the underlying circuitry.

The Constraint of High Temperature: Thermal Budget

The primary drawback of high-temperature LPCVD is the significant thermal budget. Many advanced semiconductor devices contain structures or materials (like aluminum metallization) that cannot withstand such high temperatures.

Exposing a completed transistor with aluminum contacts to 800°C would destroy the device. For this reason, LPCVD nitride is often deposited early in the manufacturing flow, before temperature-sensitive materials are added.

The Low-Temperature Alternative: PECVD

When a process requires silicon nitride deposition at a later stage, a different method is used: Plasma-Enhanced Chemical Vapor Deposition (PECVD).

PECVD uses an RF-induced plasma to provide the energy for the reaction, allowing deposition to occur at much lower temperatures, typically 250°C to 400°C. However, PECVD nitride films are generally lower in density, have higher hydrogen content, and are less chemically robust than their high-temperature LPCVD counterparts.

Making the Right Choice for Your Application

The choice of deposition method and temperature is dictated entirely by the film's purpose and its position within the overall manufacturing sequence.

- If your primary focus is a robust dielectric or diffusion barrier: Standard, high-temperature LPCVD (700-900°C) is the only choice for achieving the required density and chemical stability.

- If your primary focus is minimizing film stress for MEMS or thick layers: A specialized low-stress LPCVD recipe is required, which still operates in a high-temperature window but uses different gas ratios.

- If your primary focus is depositing a passivation layer on a completed device with metal: You must use a lower-temperature alternative like PECVD to avoid exceeding the thermal budget of the underlying components.

Ultimately, understanding the relationship between temperature and film properties empowers you to select the process that meets your specific engineering goal.

Summary Table:

| Parameter | Typical Range | Key Impact |

|---|---|---|

| Standard LPCVD SiN Temperature | 700°C - 900°C | Produces high-density, stoichiometric Si₃N₄ films |

| Low-Temperature Alternative (PECVD) | 250°C - 400°C | Suitable for temperature-sensitive applications |

| Primary Trade-off | High Temp (LPCVD) vs. Low Temp (PECVD) | Film quality vs. thermal budget constraints |

Need to Optimize Your Silicon Nitride Deposition Process?

Choosing the right deposition temperature is critical for achieving the desired film properties in your semiconductor or MEMS application. KINTEK specializes in providing high-performance lab equipment and consumables tailored to your laboratory's precise thermal processing needs.

Our expertise in LPCVD systems and thermal solutions can help you:

- Achieve superior film density and chemical resistance

- Balance thermal budget constraints with performance requirements

- Scale your process from R&D to production

Let's discuss your specific application requirements. Contact our experts today to find the perfect solution for your lab.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor