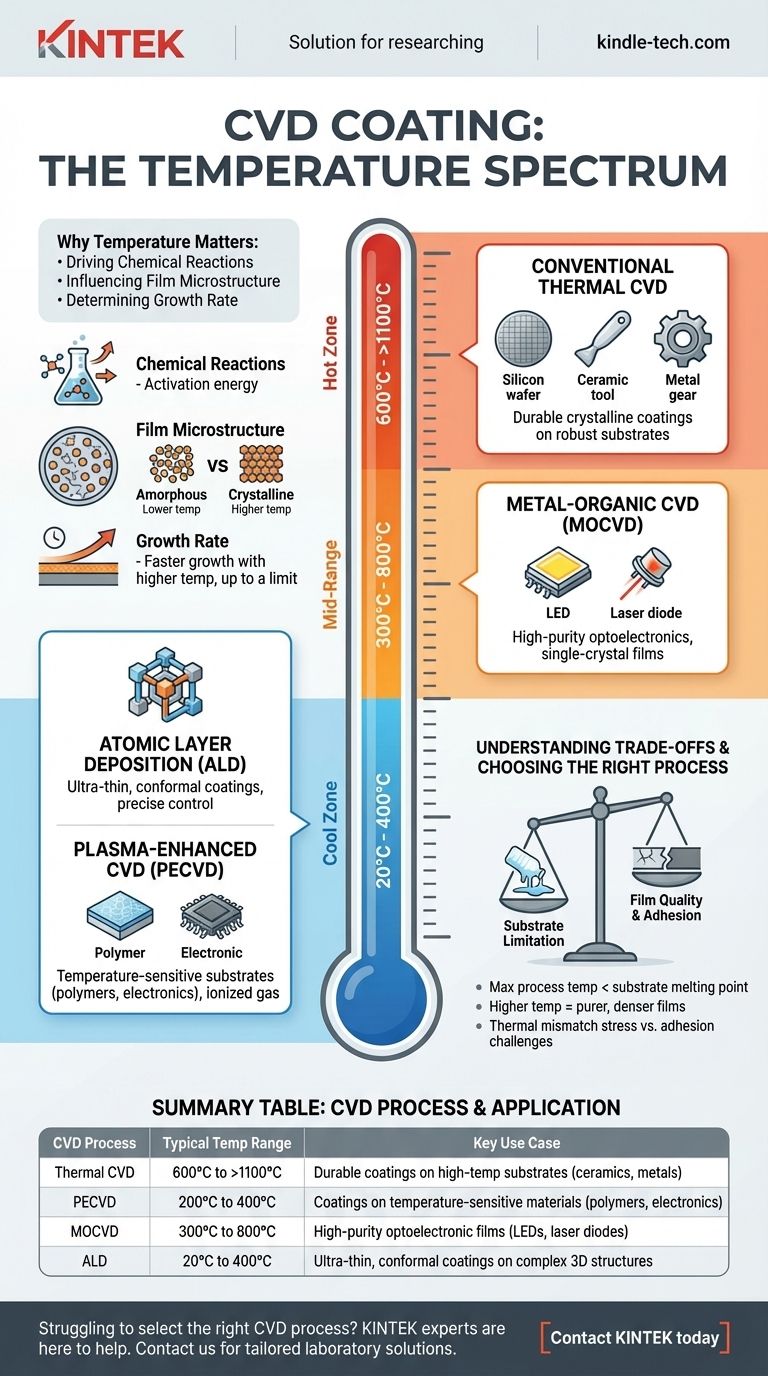

The temperature for Chemical Vapor Deposition (CVD) is not a single value but spans a wide range, from as low as 200°C to well over 1100°C. The specific temperature required is dictated by the type of CVD process being used, the precursor chemicals involved, and the desired properties of the final coating. For conventional thermal CVD, temperatures typically fall between 600°C and 900°C.

The central challenge is not finding a single "CVD temperature," but understanding that temperature is the primary lever controlling the trade-off between film quality, deposition speed, and the types of materials you can coat. Selecting the right CVD process is fundamentally a decision about managing heat.

Why Temperature is the Critical Factor in CVD

Temperature is the engine of the CVD process. It provides the necessary activation energy to initiate and sustain the chemical reactions that form the thin film on a substrate's surface. Its precise control directly influences every critical outcome.

Driving Chemical Reactions

The primary role of heat in thermal CVD is to break down the precursor gases introduced into the reaction chamber. Each chemical precursor has a specific temperature at which it will decompose (pyrolysis) and react to form the desired solid material. Insufficient temperature results in no reaction, while excessive temperature can cause unwanted gas-phase reactions, leading to particle formation and poor film quality.

Influencing Film Microstructure

Temperature has a profound effect on the final structure of the coating.

- Higher temperatures generally provide more energy for atoms to arrange themselves into a stable, ordered, crystalline lattice. This results in denser, harder, and more robust films.

- Lower temperatures may only provide enough energy for an amorphous or polycrystalline structure to form. These films are less dense and may have different mechanical or optical properties.

Determining Growth Rate

Generally, a higher process temperature increases the reaction rate, leading to faster film growth. However, this relationship is not infinite. At very high temperatures, the reaction can become limited by the rate at which precursor gas can be supplied to the surface, causing the growth rate to plateau or even decrease.

A Spectrum of CVD Processes and Temperatures

The term "CVD" encompasses a family of techniques, many of which were specifically developed to lower the process temperature and expand the range of compatible substrates.

Conventional Thermal CVD

This is the original and most straightforward CVD method. It relies solely on high temperature to drive the reaction.

- Temperature Range: 600°C to >1100°C

- Use Case: Ideal for highly durable, crystalline coatings like silicon nitride (Si₃N₄) or titanium nitride (TiN) on substrates that can withstand extreme heat, such as silicon wafers, ceramics, or metal tools.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas) within the chamber. This energetic plasma provides the energy to break down precursor gases, significantly reducing the need for high thermal energy.

- Temperature Range: 200°C to 400°C

- Use Case: Essential for depositing films on temperature-sensitive substrates like polymers, plastics, and fully assembled electronic components that would be damaged by high heat.

Metal-Organic CVD (MOCVD)

MOCVD uses metal-organic precursors, which typically decompose at lower temperatures than their inorganic halide counterparts used in conventional CVD. It is prized for its ability to grow high-purity, single-crystal films.

- Temperature Range: 300°C to 800°C

- Use Case: The dominant technology for manufacturing high-performance optoelectronics, such as LEDs and laser diodes, where precise control over crystalline quality is paramount.

Atomic Layer Deposition (ALD)

Often considered a subclass of CVD, ALD operates by introducing precursors in a sequential, self-limiting manner. This allows for unparalleled thickness control, one atomic layer at a time, at very low temperatures.

- Temperature Range: 20°C to 400°C

- Use Case: Perfect for creating ultra-thin, highly conformal coatings on complex 3D structures, such as in advanced microelectronics and MEMS devices.

Understanding the Trade-offs: Temperature vs. Quality

Choosing a CVD process is an exercise in managing competing priorities. The temperature you can use forces critical trade-offs.

The Substrate Limitation

This is the most significant constraint. The maximum process temperature must always be lower than the melting or degradation point of the substrate material. A 900°C thermal CVD process is impossible for a plastic substrate that melts at 250°C, making a low-temperature process like PECVD the only viable option.

Film Purity and Density

Higher temperatures generally produce purer, denser films. Low-temperature processes like PECVD can result in the incorporation of byproducts, such as hydrogen, into the film. This can alter its density, refractive index, and stress levels.

Stress and Adhesion

The difference in thermal expansion between the coating and the substrate can induce significant stress in the film as it cools. High-temperature processes can exacerbate this issue, potentially leading to cracking or delamination. While lower-temperature processes reduce this thermal mismatch stress, they can sometimes face challenges with film adhesion if the surface is not adequately prepared.

Making the Right Choice for Your Goal

Your choice of CVD process depends entirely on the material you are coating and the properties you need to achieve.

- If your primary focus is maximum hardness and purity on a robust substrate (like ceramic or metal): High-temperature thermal CVD is your most direct path to a high-quality, dense coating.

- If your primary focus is coating a temperature-sensitive material (like a polymer or assembled device): A low-temperature process like PECVD is the necessary choice.

- If your primary focus is ultimate conformity and thickness control on a complex shape: ALD offers unparalleled precision, even at very low temperatures.

- If your primary focus is creating high-quality epitaxial films for optoelectronics: MOCVD provides the control needed for complex, single-crystal device structures.

By understanding the relationship between temperature, process, and film properties, you can select the deposition strategy that perfectly aligns with your technical requirements.

Summary Table:

| CVD Process | Typical Temperature Range | Key Use Case |

|---|---|---|

| Thermal CVD | 600°C to >1100°C | Durable coatings on high-temp substrates (ceramics, metals) |

| PECVD | 200°C to 400°C | Coatings on temperature-sensitive materials (polymers, electronics) |

| MOCVD | 300°C to 800°C | High-purity optoelectronic films (LEDs, laser diodes) |

| ALD | 20°C to 400°C | Ultra-thin, conformal coatings on complex 3D structures |

Struggling to select the right CVD process for your specific substrate and coating requirements? The experts at KINTEK are here to help. We specialize in providing laboratory equipment and consumables tailored to your unique deposition needs. Whether you're working with high-temperature ceramics or sensitive polymers, our team can guide you to the optimal solution for achieving superior film quality, adhesion, and performance.

Contact KINTEK today to discuss how our expertise can enhance your coating process and deliver the results you need.

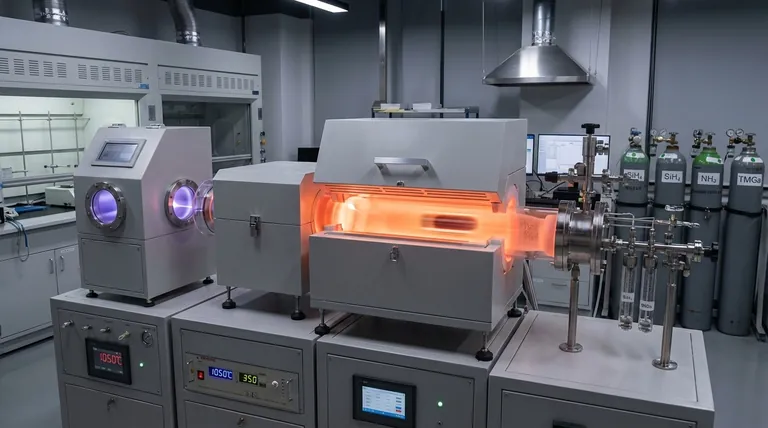

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the mechanism of MOCVD? Precise Thin Film Deposition for High-Performance Semiconductors

- Why RF sputtering is better than DC sputtering? The Ultimate Guide to Material Deposition

- What is the primary function of a horizontal MOCVD reactor? Achieve Precise InGaN Single-Crystal Growth

- Why is a vacuum waveguide system necessary for large-area plasma in MW-SWP CVD? Overcome Structural Scaling Limits

- What is the process of aluminum sputtering? A Guide to Thin Film Deposition

- What role does a vacuum CVD system play in Parylene C neural implant encapsulation? Achieve High-Purity Bio-Shielding

- Is there a way to mass produce graphene? Unlock Industrial-Scale Production with CVD Technology

- What is CVD coating? Transform Your Material's Surface for Maximum Performance