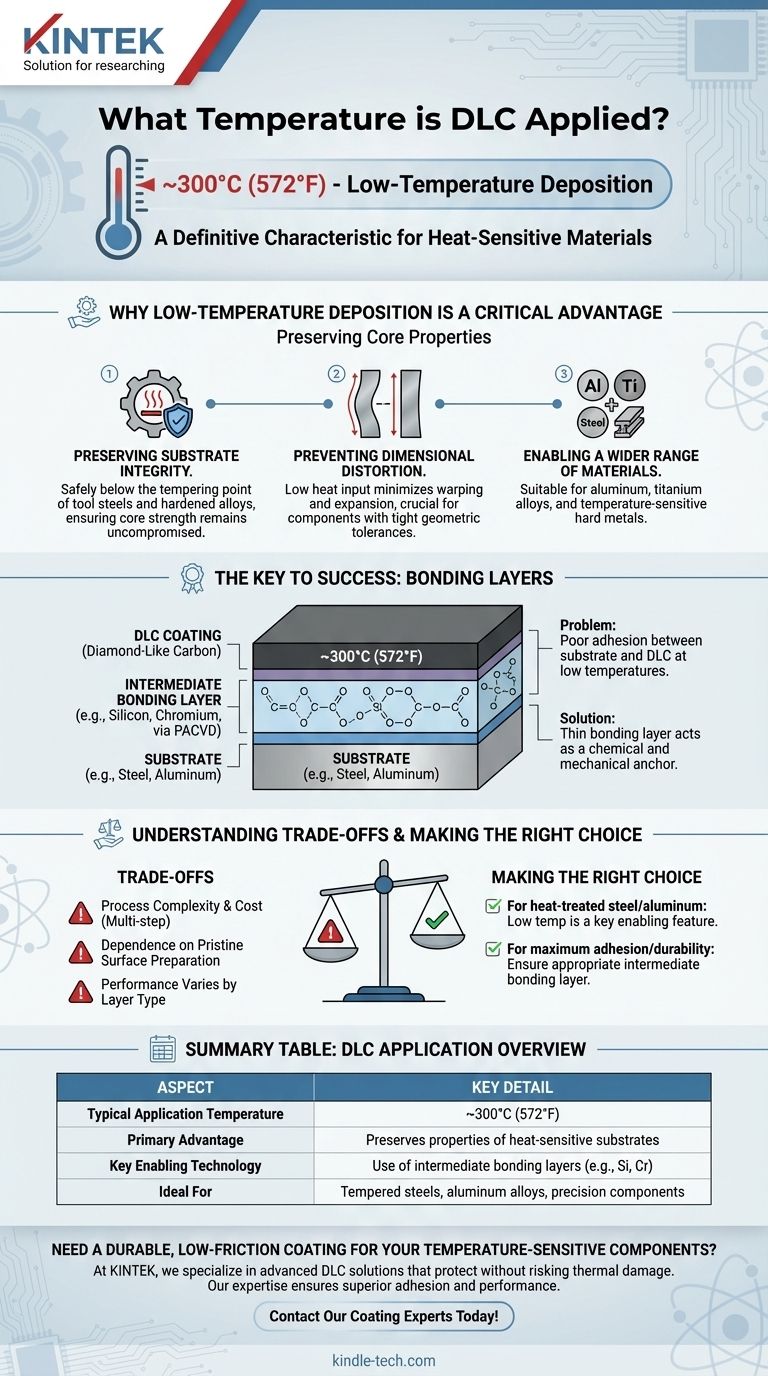

In practice, Diamond-Like Carbon (DLC) coatings are typically applied at relatively low temperatures, generally around 300°C (572°F). This low deposition temperature is a defining characteristic of many DLC processes, especially when compared to other hard coatings that require much higher heat.

The critical takeaway is not just the temperature itself, but what it enables. DLC's low application temperature allows for the coating of heat-sensitive materials, such as tempered steels or aluminum alloys, without damaging their underlying structural properties.

Why Low-Temperature Deposition is a Critical Advantage

The ability to apply a hard, wear-resistant coating at low temperatures solves a fundamental engineering problem. Many high-performance components rely on precise heat treatments to achieve their desired strength and hardness.

Preserving Substrate Integrity

Applying a coating at a temperature higher than the material's tempering point would ruin its properties. A process at ~300°C is safely below the tempering temperature of most tool steels and other hardened alloys, ensuring the component's core strength is not compromised.

Preventing Dimensional Distortion

High heat can cause parts to warp, expand, or distort. For components with tight geometric tolerances, even minor changes are unacceptable. The low heat input of the DLC process minimizes this risk, preserving the part's final dimensions.

Enabling a Wider Range of Materials

Because the process is not thermally aggressive, DLC can be successfully applied to materials that cannot withstand high-heat coating methods. This includes aluminum, titanium alloys, and even some temperature-sensitive hard metals.

The Key to Low-Temperature Success: Bonding Layers

Achieving strong adhesion at low temperatures is a significant technical challenge. This is overcome through the strategic use of intermediate layers that act as a bridge between the substrate and the final DLC film.

The Challenge of Adhesion

Without sufficient heat, atoms are less mobile, making it difficult to form a strong, dense, and well-bonded connection directly between the substrate (like steel) and the carbon film. A direct application could result in a coating that easily flakes or peels off under stress.

How Intermediate Layers Work

To solve this, a thin bonding layer is often deposited first using a process like Plasma-Assisted Chemical Vapor Deposition (PACVD). Materials like silicon or chromium are commonly used for this purpose. This layer functions like a sophisticated primer, creating a strong chemical and mechanical anchor for the subsequent DLC coating.

Understanding the Trade-offs

While highly advantageous, the use of interlayers to achieve low-temperature adhesion introduces certain considerations that are important for any technical evaluation.

Process Complexity and Cost

The addition of a bonding layer means the coating process is a multi-step procedure. This can add to the overall complexity, time, and cost compared to a theoretical single-layer deposition.

Dependence on Surface Preparation

The success of any coating, especially a multi-layered one, is critically dependent on pristine surface preparation. Any contamination on the substrate can compromise the bonding layer, leading to a failure of the entire coating system.

Performance Varies by Layer Type

The specific intermediate layer used (e.g., silicon, chromium, tungsten carbide) can influence the final properties of the coating system, such as its internal stress, friction coefficient, and overall durability. The choice is tailored to the substrate and the application's demands.

Making the Right Choice for Your Application

Your material and performance goals will determine the importance of the DLC application temperature.

- If your primary focus is coating heat-treated steel or aluminum: The low temperature of DLC is a key enabling feature, making it an ideal choice to add surface performance without damaging the part.

- If your primary focus is maximum adhesion and durability: Ensure your coating provider uses an appropriate intermediate bonding layer engineered for your specific substrate material.

By understanding the relationship between temperature, adhesion, and the substrate, you can leverage DLC technology to achieve superior performance without compromise.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Typical Application Temperature | ~300°C (572°F) |

| Primary Advantage | Preserves the properties of heat-sensitive substrates |

| Key Enabling Technology | Use of intermediate bonding layers (e.g., silicon, chromium) |

| Ideal For | Tempered steels, aluminum alloys, and precision components |

Need a durable, low-friction coating for your temperature-sensitive components?

At KINTEK, we specialize in advanced DLC coating solutions that protect your lab equipment and precision parts without risking thermal damage. Our expertise in low-temperature Plasma-Assisted Chemical Vapor Deposition (PACVD) processes ensures superior adhesion and performance for materials like aluminum and tempered steels.

Let us enhance the wear resistance and lifespan of your critical components.

Contact our coating experts today to discuss your specific application and receive a tailored solution!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition