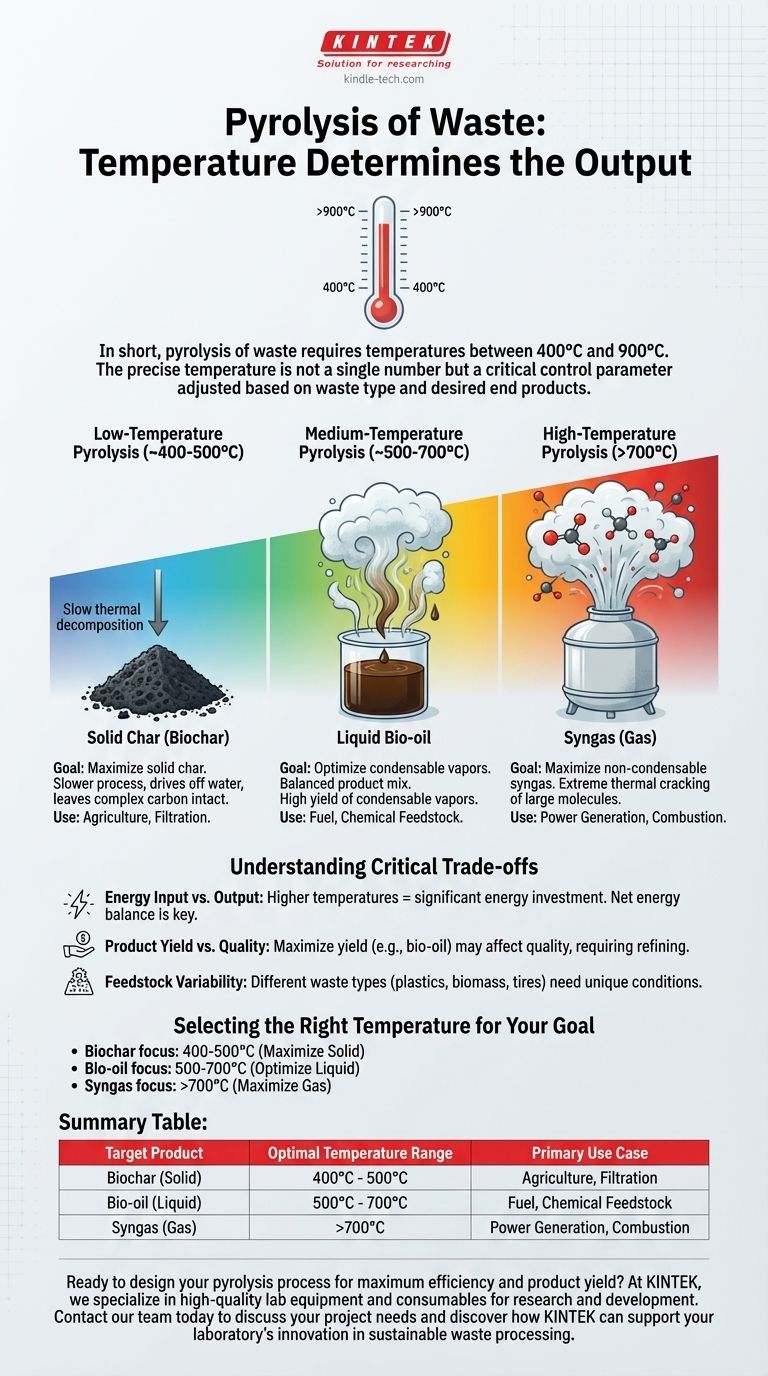

In short, pyrolysis of waste requires temperatures between 400°C and 900°C. The precise temperature is not a single number but a critical control parameter that you must adjust based on the specific type of waste being processed and, most importantly, the end products you want to create.

The central challenge is not finding one "correct" temperature, but understanding that temperature directly determines the output of the pyrolysis process. Lower temperatures favor solid char, while higher temperatures favor the production of liquids and gases.

How Temperature Dictates Pyrolysis Outcomes

Pyrolysis is the thermal decomposition of materials in the absence of oxygen. The temperature you apply directly controls the rate and extent of the chemical reactions that break down the waste material.

Low-Temperature Pyrolysis (~400-500°C)

At this lower end of the spectrum, the process is often slower. The heat is sufficient to drive off water and volatile compounds but leaves more of the complex carbon structures intact.

This approach is intentionally used to maximize the production of solid char, also known as biochar.

Medium-Temperature Pyrolysis (~500-700°C)

This range is often considered the most balanced for producing a mix of products, and it is the most common for converting waste into energy.

The higher thermal energy breaks down the feedstock more completely, creating a high yield of condensable vapors that form liquid bio-oil upon cooling.

High-Temperature Pyrolysis (>700°C)

Pushing the temperature above 700°C drives thermal cracking to its extreme. Large organic molecules are broken down into the simplest, smallest gas molecules.

This method is used to maximize the yield of non-condensable synthesis gas (syngas), a mixture primarily of hydrogen and carbon monoxide that can be used as a fuel.

Understanding the Critical Trade-offs

Choosing a temperature is an exercise in balancing competing factors. What is optimal for one goal is often suboptimal for another.

Energy Input vs. Output

Achieving and maintaining higher temperatures requires a significant energy investment. A key consideration for any operation is the net energy balance—ensuring the energy value of the products is greater than the energy consumed by the process.

Product Yield vs. Quality

While a specific temperature might maximize the yield of one product (e.g., bio-oil), it may also affect its quality. Higher temperatures can sometimes lead to more complex and less stable compounds in the liquid fraction, requiring more intensive upgrading or refining.

Feedstock Variability

Different types of waste break down at different temperatures. Plastics, biomass, and tires all have unique chemical compositions that dictate their ideal processing conditions. A single, fixed temperature is rarely efficient for a mixed waste stream.

Selecting the Right Temperature for Your Goal

To determine the correct temperature, you must first define your primary objective.

- If your primary focus is producing solid biochar for agricultural use or filtration: Operate in the lower range of 400-500°C to maximize the solid yield.

- If your primary focus is creating liquid bio-oil for use as a fuel or chemical feedstock: Target the medium temperature range of 500-700°C to optimize the yield of condensable vapors.

- If your primary focus is generating syngas for direct combustion or power generation: Employ a high temperature range above 700°C to ensure maximum conversion of the feedstock into gas.

Ultimately, temperature is the most powerful lever you have to steer the output of your waste-to-value process.

Summary Table:

| Target Product | Optimal Temperature Range | Primary Use Case |

|---|---|---|

| Biochar (Solid) | 400°C - 500°C | Agriculture, Filtration |

| Bio-oil (Liquid) | 500°C - 700°C | Fuel, Chemical Feedstock |

| Syngas (Gas) | >700°C | Power Generation, Combustion |

Ready to design your pyrolysis process for maximum efficiency and product yield?

The precise temperature control discussed here is critical for success. At KINTEK, we specialize in providing high-quality lab equipment and consumables for research and development in waste conversion and pyrolysis. Whether you are optimizing biochar production or scaling up syngas generation, our reactors, temperature controllers, and analytical tools are designed for accuracy and reliability.

Let our experts help you select the right equipment to achieve your specific goals. Contact our team today to discuss your project needs and discover how KINTEK can support your laboratory's innovation in sustainable waste processing.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory High Pressure Vacuum Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the high temperature of a tube furnace? Unlock the Right Model for Your Application

- What material is a muffle tube? A Guide to High-Temperature Ceramic Tubes

- What is the principle of a tube furnace? Master Controlled Heating for Precise Lab Results

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses

- What is the advantage of using a dual-zone tube furnace in the preparation of CuS-MoS2 heterojunction catalysts?

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the function of a tube furnace in CVD SiC synthesis? Achieving Ultra-Pure Silicon Carbide Powders

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.