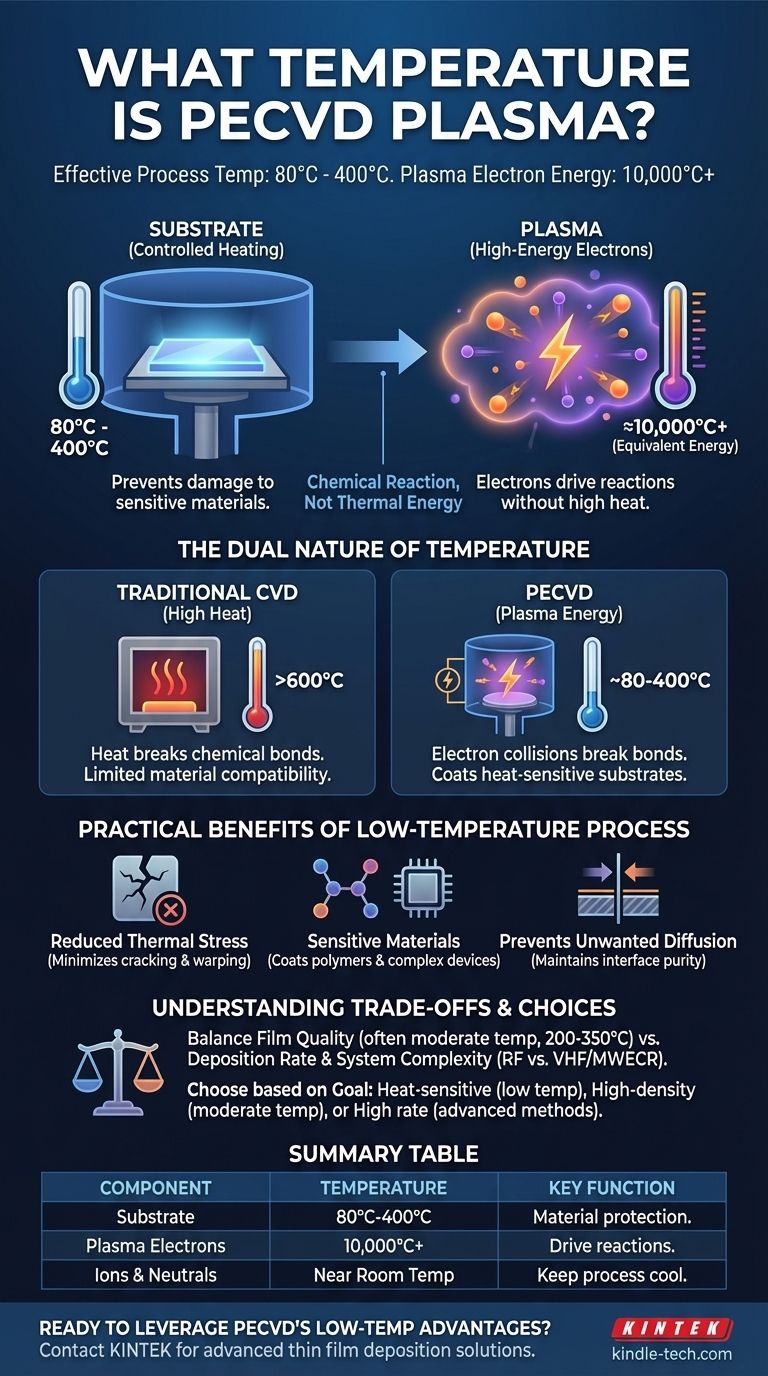

The short answer is that the effective process temperature for Plasma-Enhanced Chemical Vapor Deposition (PECVD) is typically between 80°C and 400°C. However, this number refers to the temperature of the substrate (the material being coated), not the "temperature" of the plasma itself. The plasma contains electrons with an energy equivalent to thousands of degrees, which is the key to why the overall process can run so cool.

The core principle of PECVD is not about heating the entire system. Instead, it uses the immense energy of free electrons within a plasma to drive chemical reactions, allowing for high-quality film deposition on a relatively cool substrate. This decouples reaction energy from thermal energy.

The Dual Nature of "Temperature" in PECVD

To understand PECVD, it's critical to distinguish between the heat applied to the material and the energy contained within the plasma. The process temperature you control is for the substrate, but the plasma's internal energy is what makes the chemistry work.

The Substrate Temperature: What You Control

The numbers cited in process specifications, usually between 80°C and 400°C, refer to the temperature of the substrate holder, or chuck. This is the deliberate, controlled heating of the component being coated.

This relatively low temperature is the primary advantage of PECVD. It allows for coating on materials that cannot withstand the high heat (often >600°C) required by traditional Chemical Vapor Deposition (CVD).

The Plasma Energy: The Engine of the Reaction

Plasma is an ionized gas composed of a mixture of high-energy electrons, positively charged ions, and neutral gas molecules. These components are not all at the same energy level.

The electrons are extremely light and can be accelerated to very high kinetic energies by the applied electric field (e.g., Radio Frequency or Microwave). Their "effective temperature" can be tens of thousands of degrees Celsius.

The much heavier ions and neutral molecules do not accelerate as easily and remain near room temperature. Because the electrons do all the important work, the bulk gas and the substrate can stay cool.

How Plasma Replaces High Heat

In traditional CVD, intense heat (thermal energy) is required to break the chemical bonds of the precursor gases and initiate the deposition reaction.

In PECVD, this energy is supplied by collisions with the hyper-energetic electrons in the plasma. These collisions fragment the precursor gas molecules, creating reactive species that then deposit onto the substrate surface to form the thin film.

The Practical Benefits of a Low-Temperature Process

Leveraging plasma energy instead of pure thermal energy provides several significant engineering advantages that are central to modern manufacturing.

Reduced Thermal Stress

By keeping the substrate cool, PECVD minimizes the stress caused by a mismatch in thermal expansion between the deposited film and the underlying material. This is critical for preventing film cracking, delamination, and substrate warping.

Compatibility with Sensitive Materials

The process enables the deposition of high-quality films on temperature-sensitive substrates. This includes polymers, plastics, and complex semiconductor devices with previously fabricated layers that would be damaged by excessive heat.

Preventing Unwanted Diffusion

Lower temperatures prevent atoms from diffusing between the substrate and the new film layer. This maintains the chemical purity and integrity of interfaces, which is essential for the performance of electronic and optical devices.

Understanding the Trade-offs

While powerful, the PECVD process involves balancing competing factors. The chosen temperature is just one variable in a complex optimization process.

Film Quality vs. Temperature

While a key benefit, operating at the lowest possible temperatures can sometimes compromise film quality. For example, it may lead to lower film density or the incorporation of unwanted elements like hydrogen from precursor gases. Often, a moderate temperature (e.g., 200-350°C) is an ideal compromise.

Deposition Rate vs. System Complexity

Different methods of generating plasma offer different benefits. Microwave PECVD (MWECR-PECVD) can achieve very high deposition rates at low temperatures, but these systems are often more complex and have higher maintenance costs than more common Radio Frequency (RF-PECVD) systems.

Making the Right Choice for Your Goal

The ideal process temperature is dictated entirely by the application, the substrate material, and the desired film properties.

- If your primary focus is coating a heat-sensitive substrate (like a polymer): You will leverage PECVD's main advantage by operating at the lowest possible temperature (e.g., 80-150°C) that still yields an acceptable film.

- If your primary focus is depositing a high-density, low-stress film for electronics: You will likely operate in a moderate temperature range (e.g., 250-400°C) to balance throughput with optimal film quality and low defect rates.

- If your primary focus is achieving the highest possible deposition rate: You might explore advanced methods like VHF-PECVD or MWECR-PECVD, which use plasma physics to boost reaction rates without necessarily requiring higher substrate temperatures.

Ultimately, PECVD's power comes from its strategic use of plasma to supply reaction energy, freeing you from the limitations of purely thermal processes.

Summary Table:

| PECVD Component | Effective Temperature Range | Key Function |

|---|---|---|

| Substrate (Controlled) | 80°C to 400°C | Prevents damage to sensitive materials like polymers and semiconductors. |

| Plasma Electrons (Energy Equivalent) | 10,000°C+ | Drives chemical reactions to deposit films without high thermal heat. |

| Ions & Neutral Gas Molecules | Near Room Temperature | Keeps the overall process temperature low and manageable. |

Ready to leverage PECVD's low-temperature advantages for your sensitive substrates?

KINTEK specializes in providing advanced lab equipment and consumables for precise thin film deposition. Whether you are working with delicate polymers, complex semiconductor devices, or any temperature-sensitive material, our PECVD solutions can help you achieve high-quality films without the risk of thermal damage.

Contact our experts today to discuss how we can optimize a PECVD process for your specific laboratory needs and enhance your research or production outcomes.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma assisted deposition process? Enable Low-Temperature, High-Quality Thin Films

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- What are the different types of Plasma Enhanced Chemical Vapour Deposition (PECVD)? Compare RF, VHF, and Microwave

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What is plasma enhanced chemical vapour deposition PECVD used for? Enable Low-Temp Thin Films for Electronics & Solar

- What is plasma in PECVD? The Key to Low-Temperature, High-Quality Thin-Film Deposition