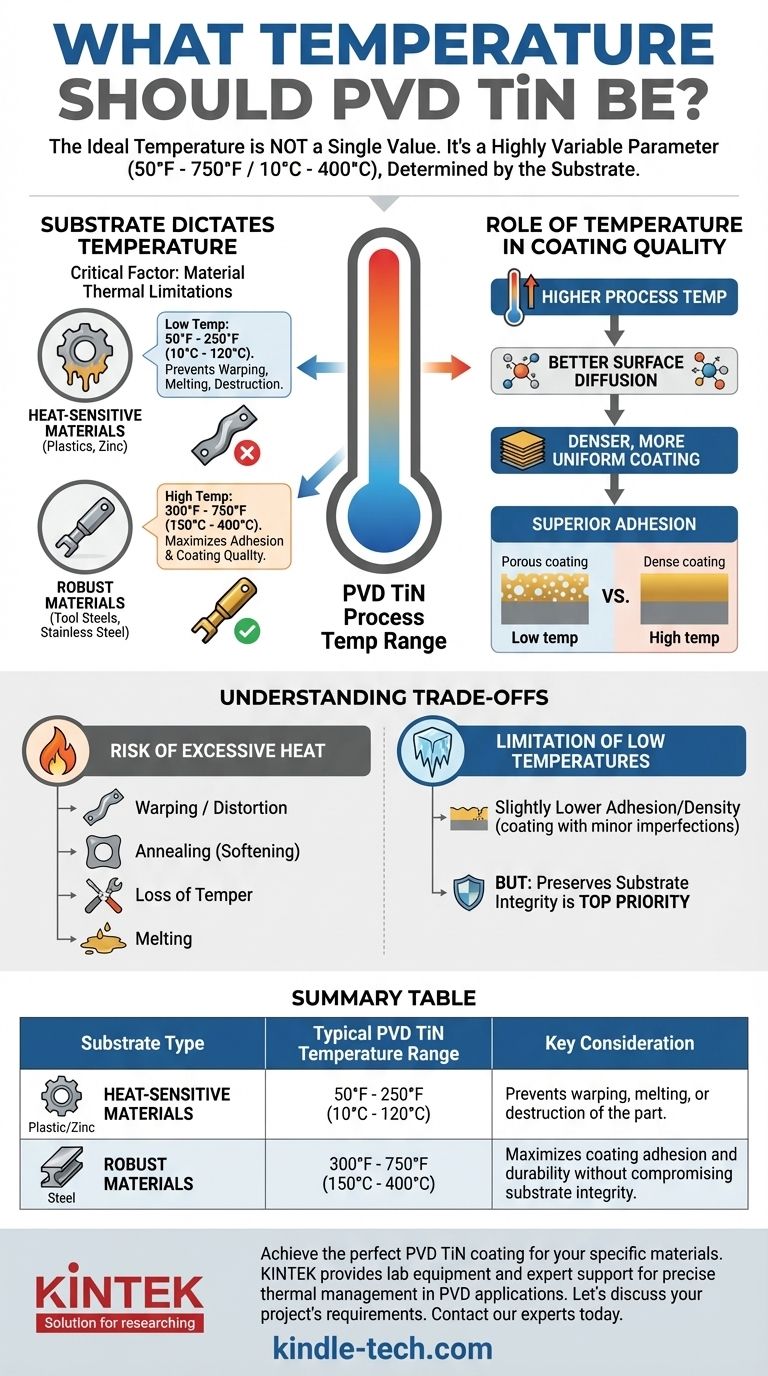

The ideal temperature for PVD TiN coating is not a single value. Instead, the process temperature for Titanium Nitride (TiN) via Physical Vapor Deposition (PVD) is a highly variable parameter, typically ranging from as low as 50°F (10°C) to as high as 750°F (400°C). The correct temperature is determined almost entirely by the thermal limitations of the substrate material you are coating.

The critical factor in selecting a PVD TiN process temperature is not the coating itself, but the material being coated. The primary goal is to use the highest temperature the substrate can safely tolerate to achieve the best adhesion and coating quality.

Why Temperature is a Variable, Not a Constant

The wide temperature range in PVD TiN application exists because the process must be adapted to a vast array of materials, each with its own thermal tolerance. The substrate is always the primary limiting factor.

The Substrate Dictates the Temperature

Different materials react to heat in fundamentally different ways. The PVD process temperature must be kept below the point where the substrate would be damaged.

For example, hardened tool steels can withstand higher temperatures without losing their temper, making them suitable for processes in the 300°F to 750°F (150°C - 400°C) range.

In contrast, heat-sensitive materials like plastics or low-melting-point metals like zinc would warp, melt, or be destroyed at those temperatures. They require a much lower process temperature, often between 50°F and 250°F (10°C - 120°C).

The Role of Temperature in Coating Quality

While the substrate sets the upper limit, temperature plays a crucial role in the coating's final properties.

Generally, a higher process temperature promotes better surface diffusion and atomic mobility. This leads to a denser, more uniform coating structure with superior adhesion to the substrate.

This is why, for durable materials like steel, operators will use the highest temperature feasible—it optimizes the bond between the coating and the part.

Understanding the Trade-offs of Temperature Selection

Choosing the correct temperature involves balancing the ideal coating properties with the physical limitations of the component. Misjudging this can lead to irreversible damage.

The Risk of Excessive Heat

Applying a temperature that is too high for the substrate is catastrophic. The potential consequences include:

- Warping or distortion of the part's geometry.

- Annealing, which softens the material and reduces its hardness.

- Loss of temper in pre-hardened steels.

- Melting of low-temperature alloys or plastics.

The Limitation of Low Temperatures

When you are forced to use a lower temperature for a sensitive substrate, you must accept a slight trade-off.

The resulting TiN coating will still be highly effective, but it may have marginally lower adhesion or density compared to a coating applied at a much higher temperature. However, preserving the integrity of the substrate is always the top priority.

Making the Right Choice for Your Application

Your material determines your process window. The decision should be based entirely on the thermal stability of the part you intend to coat.

- If your primary focus is coating heat-sensitive materials (e.g., plastics, zinc alloys, some brasses): You must operate at the lower end of the range, prioritizing the integrity of the part over achieving maximum theoretical coating density.

- If your primary focus is coating robust materials (e.g., tool steels, stainless steel, titanium): You should use the higher end of the temperature range that the material can safely handle to maximize coating adhesion and durability.

Ultimately, successful PVD TiN coating depends on treating temperature as a critical process variable adapted to your specific substrate.

Summary Table:

| Substrate Type | Typical PVD TiN Temperature Range | Key Consideration |

|---|---|---|

| Heat-Sensitive Materials (Plastics, Zinc) | 50°F - 250°F (10°C - 120°C) | Prevents warping, melting, or destruction of the part. |

| Robust Materials (Tool Steels, Stainless Steel) | 300°F - 750°F (150°C - 400°C) | Maximizes coating adhesion and durability without compromising substrate integrity. |

Achieve the perfect PVD TiN coating for your specific materials.

Selecting the right process temperature is critical for coating performance and part integrity. KINTEK specializes in providing the lab equipment and expert support needed for precise thermal management in PVD applications. Whether you're coating sensitive alloys or robust tool steels, our solutions help you optimize adhesion and prevent substrate damage.

Let's discuss your project's requirements. Contact our experts today to ensure your PVD TiN process is a success.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition