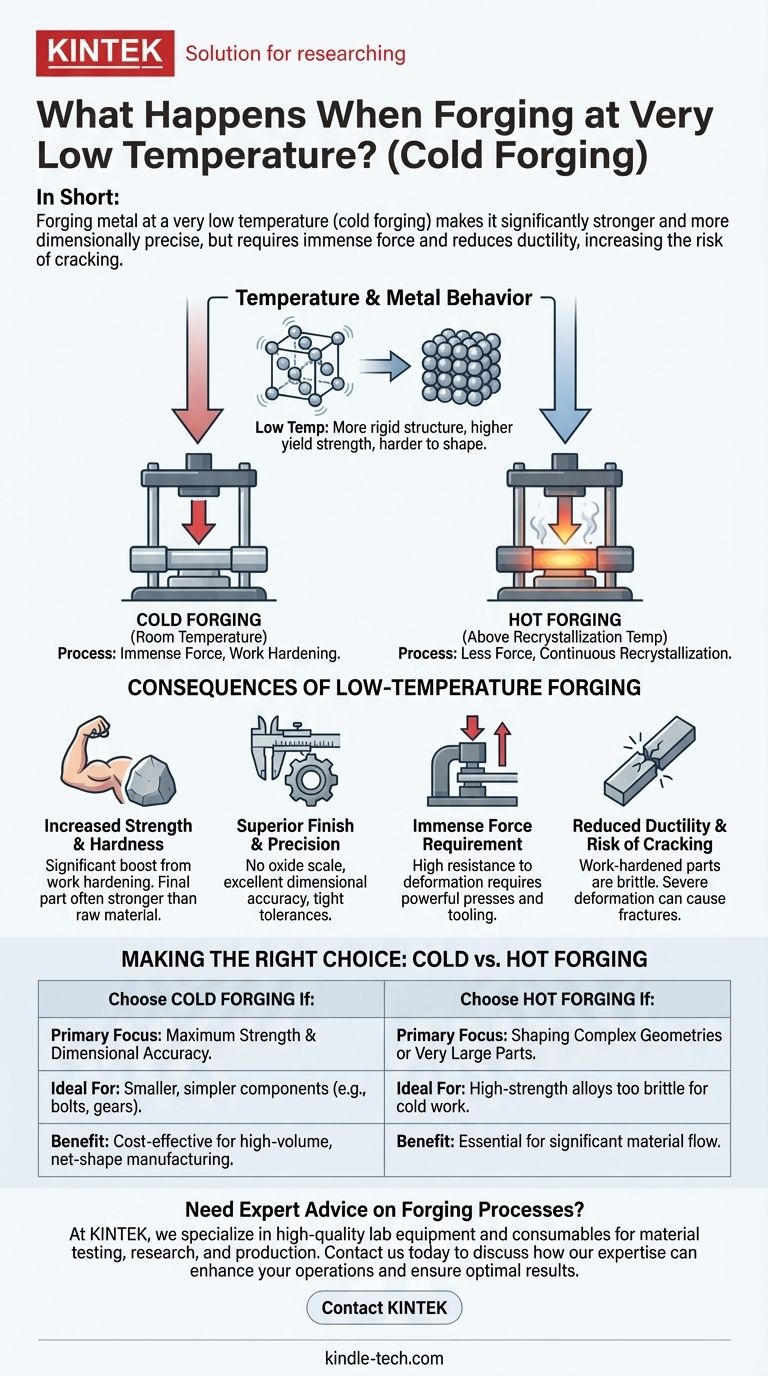

In short, forging a metal at a very low temperature makes the material significantly stronger and more dimensionally precise, but at a great cost. This process, known as cold forging, requires immense force to shape the metal and drastically reduces its ductility, increasing the risk of the material cracking or fracturing during the operation.

The temperature at which you forge metal is not simply a matter of preference; it is a fundamental engineering trade-off. Lowering the temperature sacrifices the material's workability to gain superior strength, hardness, and surface finish in the final product.

The Critical Role of Temperature in Forging

To understand the consequences of low-temperature forging, we must first understand how temperature alters a metal's fundamental properties. It's a balance between making the material easy to shape and achieving the desired final characteristics.

How Temperature Affects Metal Behavior

Heat introduces energy into a metal's crystalline structure, allowing its atoms to move more freely. This makes the metal softer, more malleable, and more ductile—meaning it can be stretched and shaped without breaking.

Conversely, at low temperatures, the atomic structure is more rigid. The material's yield strength (its resistance to permanent deformation) is much higher, making it significantly harder to shape.

Defining "Low Temperature" Forging

When we speak of forging at a "very low temperature," we are typically referring to a process performed at or near room temperature. This is formally known as cold forging.

This stands in contrast to hot forging, where the metal is heated above its recrystallization temperature. At this high temperature, the material's internal structure continuously reforms as it is being worked, preventing it from becoming brittle.

The Mechanism of Work Hardening

Deforming metal at low temperatures fundamentally changes its internal structure through a process called work hardening (or strain hardening).

As the metal is squeezed and shaped, dislocations and defects are created within its crystal lattice. These imperfections get in each other's way, making it progressively harder for the crystal planes to slip past one another. This resistance to internal movement is what makes the final part harder and stronger.

Consequences of Forging at Low Temperatures

Choosing to forge cold is a deliberate decision made to achieve specific outcomes. These results come with significant challenges that must be managed.

Benefit: Increased Strength and Hardness

The primary advantage of cold forging is the significant increase in tensile strength and hardness from work hardening. The final component can be much stronger than the raw material it was made from, and often stronger than a part that was hot forged or machined.

Benefit: Superior Surface Finish and Precision

Because cold forging is done without extreme heat, the metal does not form an oxide layer (scale) on its surface. This results in a smooth, clean finish with excellent dimensional accuracy and tight tolerances, often eliminating the need for costly secondary machining.

Challenge: Immense Force Requirement

The single greatest challenge of cold forging is the massive amount of force required. Since the material is highly resistant to deformation, the presses and hammers must be exceptionally powerful and robust, leading to higher equipment and tooling costs.

Challenge: Reduced Ductility and Risk of Cracking

The trade-off for strength is a loss of ductility. A work-hardened part is more brittle. If the deformation is too severe or performed too quickly, the internal stresses can exceed the material's limits, causing surface cracks or a complete fracture of the workpiece.

Understanding the Trade-offs: Cold vs. Hot Forging

The choice between cold and hot forging is dictated entirely by the part's design, the material being used, and the desired final properties.

When to Choose Cold Forging

Cold forging is ideal for producing smaller, simpler components in high volumes where strength and precision are paramount. It is best suited for softer, more ductile metals like low-carbon steels, copper, and aluminum alloys. Common examples include bolts, screws, and automotive parts like shafts and gears.

When Hot Forging is Necessary

Hot forging is the only option for very large parts or parts with complex shapes that require significant material flow. It is also essential for high-strength alloys (like titanium or nickel-based superalloys) that are too brittle to be worked cold. While it requires less force, it results in lower dimensional accuracy and a rougher surface finish.

Making the Right Choice for Your Goal

The "correct" forging temperature is the one that best aligns with your project's specific engineering and economic requirements.

- If your primary focus is maximum strength and dimensional accuracy: Cold forging is the superior choice, assuming the material and part geometry are suitable for the process.

- If your primary focus is shaping complex geometries or very large parts: Hot forging is essential to achieve the necessary material deformation without causing the part to fail.

- If your primary focus is net-shape manufacturing for high-volume parts: Cold forging often proves more cost-effective in the long run by minimizing material waste and eliminating secondary operations.

Ultimately, choosing the forging temperature is a strategic decision that balances the desired final properties of a part against the physical limitations of the material and the capabilities of the equipment.

Summary Table:

| Aspect | Cold Forging (Low Temperature) | Hot Forging (High Temperature) |

|---|---|---|

| Strength & Hardness | Significantly increased due to work hardening | Lower, material is softer |

| Dimensional Precision | Superior, excellent surface finish | Lower, rougher surface with scale |

| Force Required | Very high | Lower |

| Ductility | Reduced, risk of cracking | High, material is more malleable |

| Ideal For | Small, high-volume parts (e.g., bolts, gears) | Large, complex parts, high-strength alloys |

Need expert advice on selecting the right forging process for your lab or production needs?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific requirements. Whether you're working on material testing, research, or production, our solutions help you achieve precise and reliable results.

Contact us today via our contact form to discuss how our expertise can enhance your operations and ensure you choose the optimal forging method for your projects.

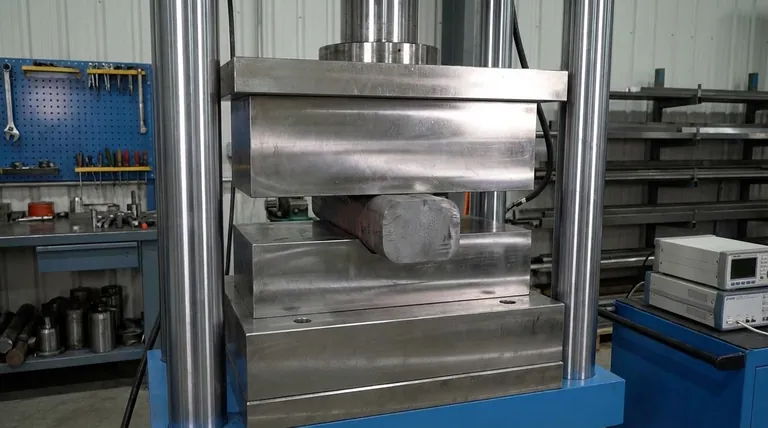

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How does a cold isostatic press contribute to the formation of TZC molybdenum alloy green bodies? Key Densification Tips

- Purpose of CIP in c-LLZO ceramic pellets? Achieve >90% Density & Superior Uniformity with Cold Isostatic Pressing

- How does a cold isostatic press improve microhardness uniformity? Achieving Consistency in TiC10/Cu-Al2O3 Composites

- What is the significance of using a cold isostatic press (CIP) to achieve pressureless sintering in LLZO? Enhance Density

- What is the isostatic pressing method? Achieve Uniform Density and Superior Material Performance

- What are the advantages of isostatic pressing? Achieve Superior Material Integrity and Design Freedom

- Why is an isostatic press used for solid electrolyte pellets? Achieve Maximum Density for Accurate Ionic Conductivity

- What role does an industrial-grade omnidirectional press play in the preparation of ultra-fine grained VT6 titanium?