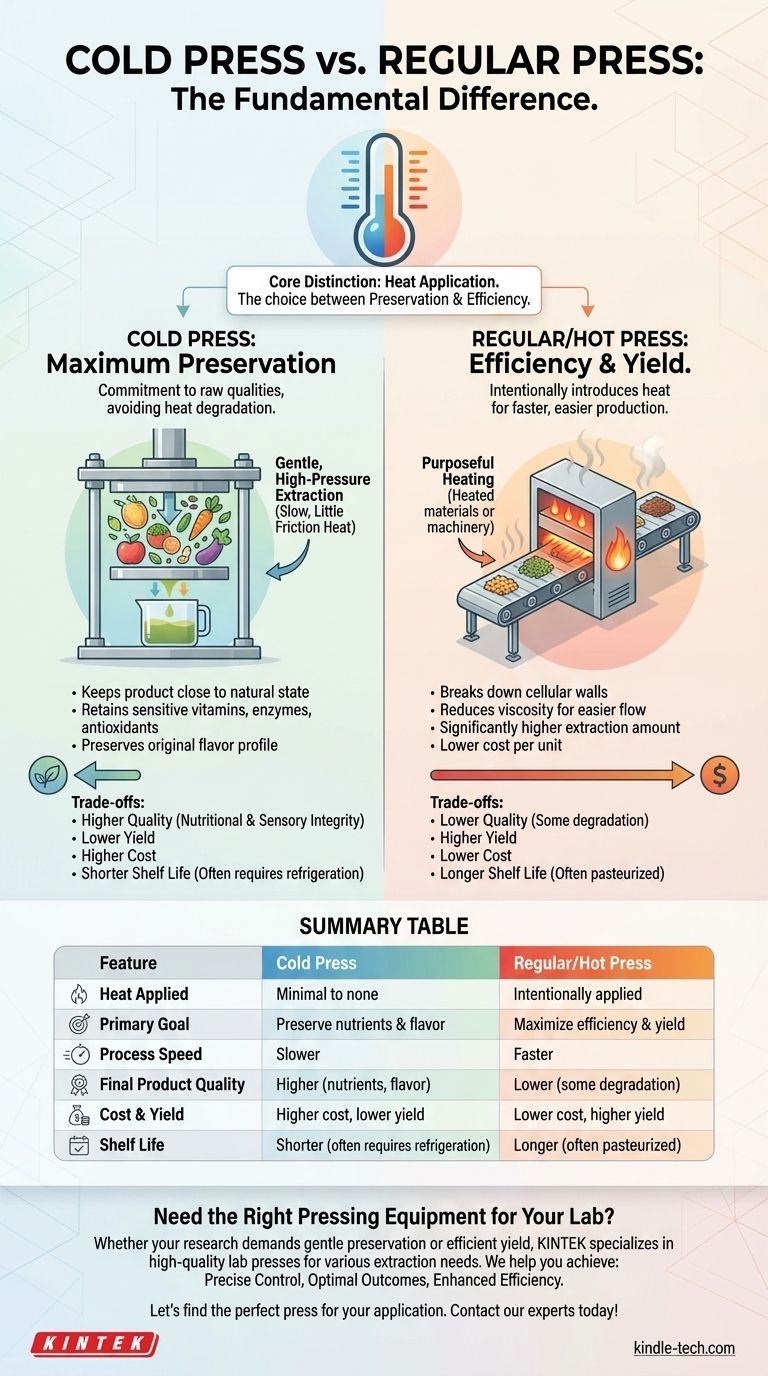

The fundamental difference is the application of heat during the extraction or formation process. Cold pressing is a method that minimizes heat, typically by using immense pressure, to extract a substance or form a material. In contrast, "regular" or conventional pressing methods often intentionally introduce heat to increase the efficiency and yield of the process.

The core distinction comes down to a choice between preservation and efficiency. Cold pressing prioritizes preserving the original chemical and nutritional integrity of the source material, while methods using heat prioritize maximizing the amount extracted.

What "Cold Press" Truly Means

The term "cold press" signifies a commitment to maintaining the raw qualities of a material by avoiding heat-induced degradation. The entire philosophy is built around preservation.

The Goal: Maximum Preservation

By not introducing external heat, cold pressing aims to keep the final product as close to its natural state as possible.

For food products like juice or olive oil, this means retaining sensitive vitamins, enzymes, and antioxidants that are easily destroyed by heat. This also preserves the original, unaltered flavor profile of the raw ingredients.

The Process: Gentle, High-Pressure Extraction

Cold press methods rely on immense physical force to squeeze out the desired substance. A common example is a hydraulic press that slowly applies pressure to ground-up fruits, vegetables, or seeds.

This process is deliberately slow and generates very little friction-based heat, ensuring the material's temperature remains low and its molecular structure is not altered by thermal processes.

The Alternative: Conventional "Hot Press" Methods

Most conventional pressing methods incorporate heat because it makes the entire process faster, easier, and more productive.

The Goal: Efficiency and Yield

Heat is a powerful tool for extraction. It breaks down the cellular walls of plants and reduces the viscosity (thickness) of oils, making them flow more easily.

This allows manufacturers to extract a significantly higher amount of product from the same amount of raw material compared to cold pressing. This increased yield directly translates to a lower cost per unit.

The Process: Purposeful Heating

In these methods, materials might be heated before being pressed, or the pressing machinery itself is heated. This is an intentional step designed to facilitate extraction.

In industrial applications, like the isostatic pressing used for powders, heat is applied to promote specific outcomes like material densification or diffusion—actively changing the material's properties under pressure.

Understanding the Critical Trade-offs

Choosing between a cold press and a heat-assisted method involves a direct trade-off between the quality of the final product and the economics of its production.

Quality vs. Quantity

This is the central conflict. Cold pressing delivers a higher-quality product in terms of nutritional and sensory integrity but produces a much lower yield.

Hot pressing sacrifices some of that nutritional and flavor complexity for a much higher yield, making the process more commercially viable and the final product more affordable.

Cost and Shelf Life

The inefficiency and slower speed of cold pressing mean the final products are almost always more expensive.

Furthermore, because cold-pressed products are not heat-treated (pasteurized), they often have a much shorter shelf life and require refrigeration, whereas many conventionally processed products are heat-pasteurized for stability.

Making the Right Choice for Your Goal

The "better" method depends entirely on what you value most in the final product.

- If your primary focus is maximum nutritional value and authentic flavor: Cold press is the superior choice, as it is specifically designed to preserve the delicate compounds found in the raw ingredients.

- If your primary focus is cost-effectiveness, shelf stability, or high yield: A conventional or hot press method is the more practical and economical option.

- If your goal is to intentionally alter a material's physical properties: A heated process, such as warm isostatic pressing, is necessary to achieve outcomes like densification that cold pressing cannot.

Ultimately, the choice of pressing method fundamentally defines the character and purpose of the final product.

Summary Table:

| Feature | Cold Press | Regular/Hot Press |

|---|---|---|

| Heat Applied | Minimal to none | Intentionally applied |

| Primary Goal | Preserve nutrients & flavor | Maximize efficiency & yield |

| Process Speed | Slower | Faster |

| Final Product Quality | Higher (nutrients, flavor) | Lower (some degradation) |

| Cost & Yield | Higher cost, lower yield | Lower cost, higher yield |

| Shelf Life | Shorter (often requires refrigeration) | Longer (often pasteurized) |

Need the Right Pressing Equipment for Your Lab?

Whether your research demands the gentle preservation of a cold press or the efficient yield of a heated process, having the right equipment is crucial. KINTEK specializes in high-quality lab equipment, including presses tailored for various extraction and material formation needs.

We help you achieve:

- Precise Control: Maintain exact temperatures for consistent, reliable results.

- Optimal Outcomes: Choose equipment perfectly suited to your goal of quality preservation or high yield.

- Enhanced Efficiency: Streamline your lab's workflow with durable and reliable machinery.

Let's find the perfect press for your application. Contact our experts today to discuss your specific laboratory requirements!

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What are the applications of cold isostatic pressing? Achieve Uniform Density for Complex Parts

- Why is cold working better than hot working? A Guide to Choosing the Right Metal Forming Process

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success

- What is isostatic pressing in powder metallurgy? Unlock Superior Part Density and Complexity

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction