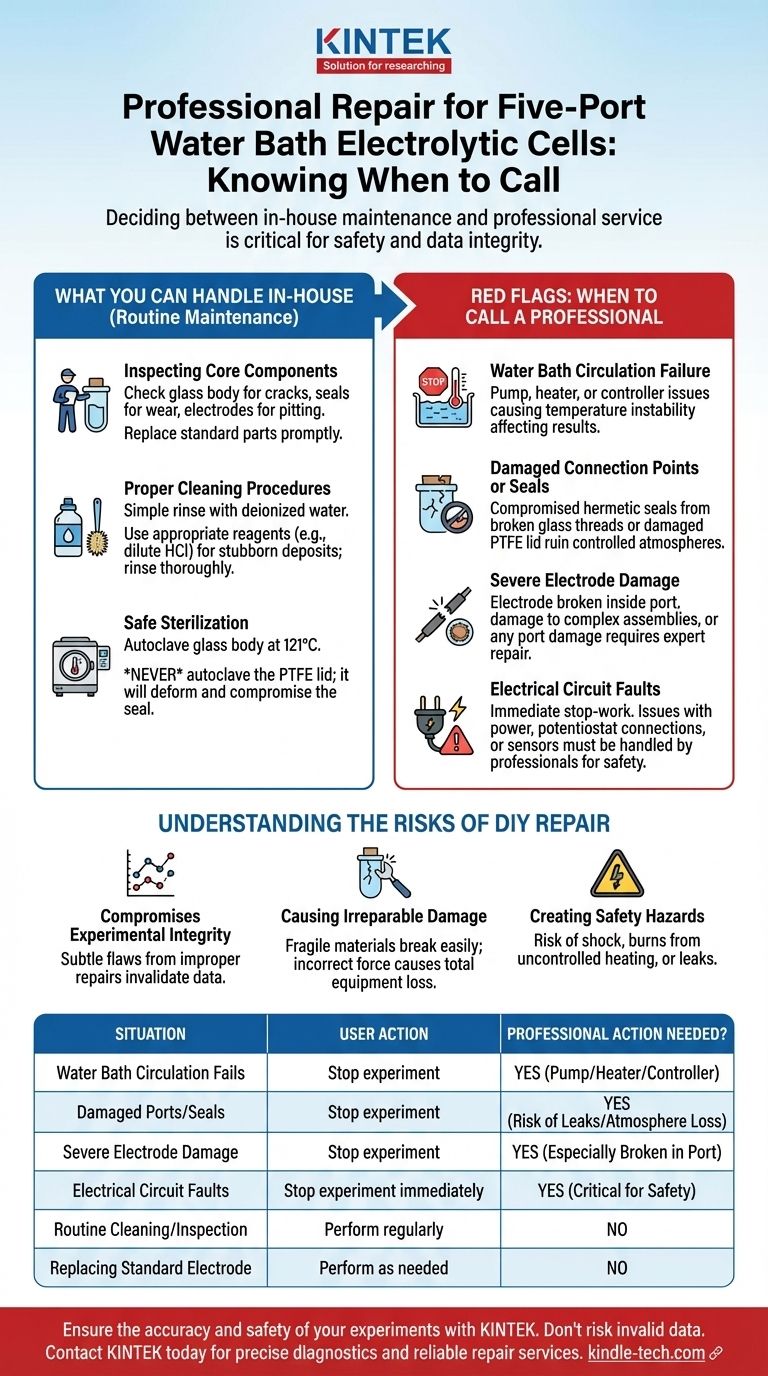

Deciding between in-house maintenance and professional repair for your five-port water bath electrolytic cell is critical for both safety and data integrity. You should seek professional service for any significant malfunction, including failures in the water bath circulation system, damage to connection points or seals, severe electrode damage, or any electrical circuit faults.

The line between user maintenance and professional repair is defined by complexity and risk. Routine cleaning and simple part swaps are user tasks, but any issue affecting the cell's core structural, thermal, or electrical integrity requires expert intervention to prevent irreparable damage and ensure experimental validity.

What You Can Handle In-House: Routine Maintenance

Proper routine care is your first line of defense against system failure. These are the tasks you can and should perform regularly to keep your electrolytic cell in optimal condition.

Inspecting Core Components

Regularly inspect the cell's glass body for any chips or cracks. Check the seals for signs of wear or degradation and examine the electrodes for pitting or contamination.

Promptly replacing any user-serviceable part, like a standard electrode, at the first sign of damage is crucial for maintaining experimental consistency.

Proper Cleaning Procedures

For routine cleaning, a simple rinse with deionized water is often sufficient. Stubborn deposits, such as metal oxides, require chemical cleaning.

Use an appropriate reagent, like dilute hydrochloric acid for rust, but carefully control the concentration and duration to avoid damaging the cell. Always follow a chemical clean with a thorough rinsing using deionized water to remove all residue.

Safe Sterilization

The glass body of the cell can be safely sterilized in an autoclave at 121°C.

However, the Polytetrafluoroethylene (PTFE) lid must never be autoclaved or heated. It will expand and likely not return to its original shape, compromising the seal of the entire assembly.

Red Flags: When to Call a Professional

Attempting to fix complex systems without specialized knowledge can lead to further damage or safety hazards. The following issues are clear indicators that you need to contact a qualified technician.

Water Bath Circulation Failure

The water bath is a dynamic thermal control system, not just a container of water. If it fails to circulate or maintain the set temperature, it points to a complex problem with the pump, heater, or controller.

Inaccurate temperature control will directly and adversely affect your experimental results.

Damaged Connection Points or Seals

The electrode ports and gas inlets are precision-engineered interfaces. Damage to the glass threads, port edges, or the custom PTFE lid compromises the cell's hermetic seal.

An imperfect seal can ruin experiments that require a controlled atmosphere and is not something that can be patched with a temporary fix.

Severe Electrode Damage

While replacing a standard plug-in electrode is a user task, severe damage is different. This includes an electrode breaking off inside a port, damage to a complex integrated assembly like a rotating disk electrode, or any damage that affects the port itself.

Electrical Circuit Faults

Any suspected electrical issue is an immediate stop-work situation. This includes problems with power, connections to a potentiostat, or integrated sensors.

For your safety and to protect connected instrumentation, all electrical diagnostics and repairs must be handled by a professional.

Understanding the Trade-offs: The Risks of DIY Repair

Knowing your limits is a sign of expertise. Attempting an advanced repair can introduce significant risks that far outweigh any potential cost savings.

Compromising Experimental Integrity

An improper repair—even one that seems to work—can introduce subtle flaws. A micro-leak, thermal instability, or chemical contamination from an incorrect sealant will invalidate your data.

Causing Irreparable Damage

Electrolytic cells are made of fragile materials like glass and specialized polymers like PTFE. A slip of a tool or the application of incorrect force can turn a repairable problem into a total loss of the equipment.

Creating Safety Hazards

Working with malfunctioning electrical components creates a risk of shock. A damaged water bath system can lead to leaks or uncontrolled heating, posing a burn risk. These are not risks worth taking.

Making the Right Choice for Your Lab

Your decision should always prioritize safety and the quality of your research. Use these guidelines to make a clear choice.

- If your primary focus is experimental accuracy: Immediately stop use and seek professional repair for any fault in the thermal control, sealing, or electrical systems.

- If your primary focus is equipment longevity: Commit to a strict routine of user-level inspection and cleaning, and never attempt to force components or repair structural damage yourself.

- If your primary focus is safety: Defer all electrical issues and failures within the high-temperature water bath system to qualified technicians without exception.

Ultimately, knowing the boundary between your role in maintenance and a technician's role in repair is fundamental to running a safe and effective laboratory.

Summary Table:

| Situation | User Action | Professional Action Needed? |

|---|---|---|

| Water Bath Circulation Fails | Stop experiment | Yes - Pump, heater, or controller issue |

| Damaged Ports/Seals | Stop experiment | Yes - Risk of leaks and atmospheric control loss |

| Severe Electrode Damage | Stop experiment | Yes - Especially if port is damaged or electrode is broken inside |

| Electrical Circuit Faults | Stop experiment immediately | Yes - Critical for safety and instrument protection |

| Routine Cleaning/Inspection | Perform regularly | No |

| Replacing Standard Electrode | Perform as needed | No |

Ensure the accuracy and safety of your experiments with KINTEK.

Don't risk invalid data or equipment damage by attempting complex repairs. Our experts specialize in servicing laboratory equipment like your five-port water bath electrolytic cell. We provide precise diagnostics and reliable repairs to restore your cell's thermal control, sealing integrity, and electrical safety, ensuring your research continues without compromise.

Contact KINTEK today for professional repair services and keep your lab running safely and efficiently.

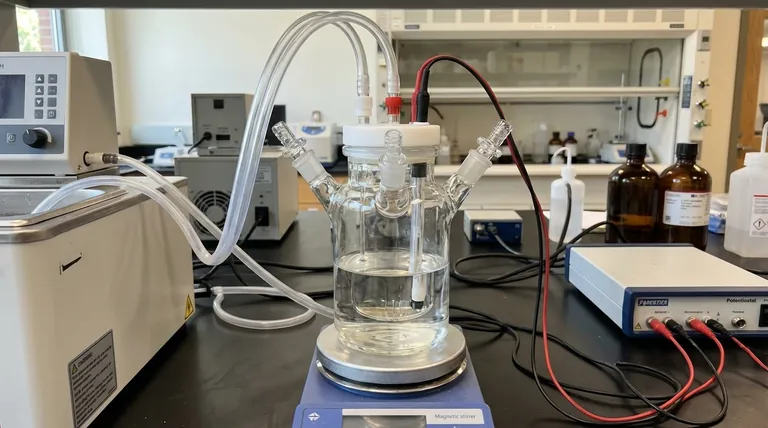

Visual Guide

Related Products

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell with Five-Port

- H Type Electrolytic Cell Triple Electrochemical Cell

People Also Ask

- What are the standard aperture specifications of the electrolytic cell? Key Sizes for Your Electrochemical Setup

- What are the key features of the five-port water bath electrolytic cell? Precision Control for Electrochemical Experiments

- When is professional repair required for a double-layer water-bath electrolytic cell? Protect Your Lab's Precision and Safety

- What are the standard aperture sizes on the lid of the multifunctional electrolytic cell? Key Ports for Your Electrochemical Setup

- What are the procedures for after using a double-layer water-bath electrolytic cell? Ensure Equipment Longevity and Data Accuracy