An electrode holder must be replaced as soon as you identify critical signs of physical damage or a noticeable decline in performance. Key indicators include cracked insulation, worn jaws that fail to grip the electrode firmly, or consistent overheating during normal operation.

The decision to replace an electrode holder is not about maximizing its lifespan; it is about guaranteeing operator safety and weld quality. Viewing the holder as a critical safety device, rather than just a tool, clarifies when replacement is non-negotiable.

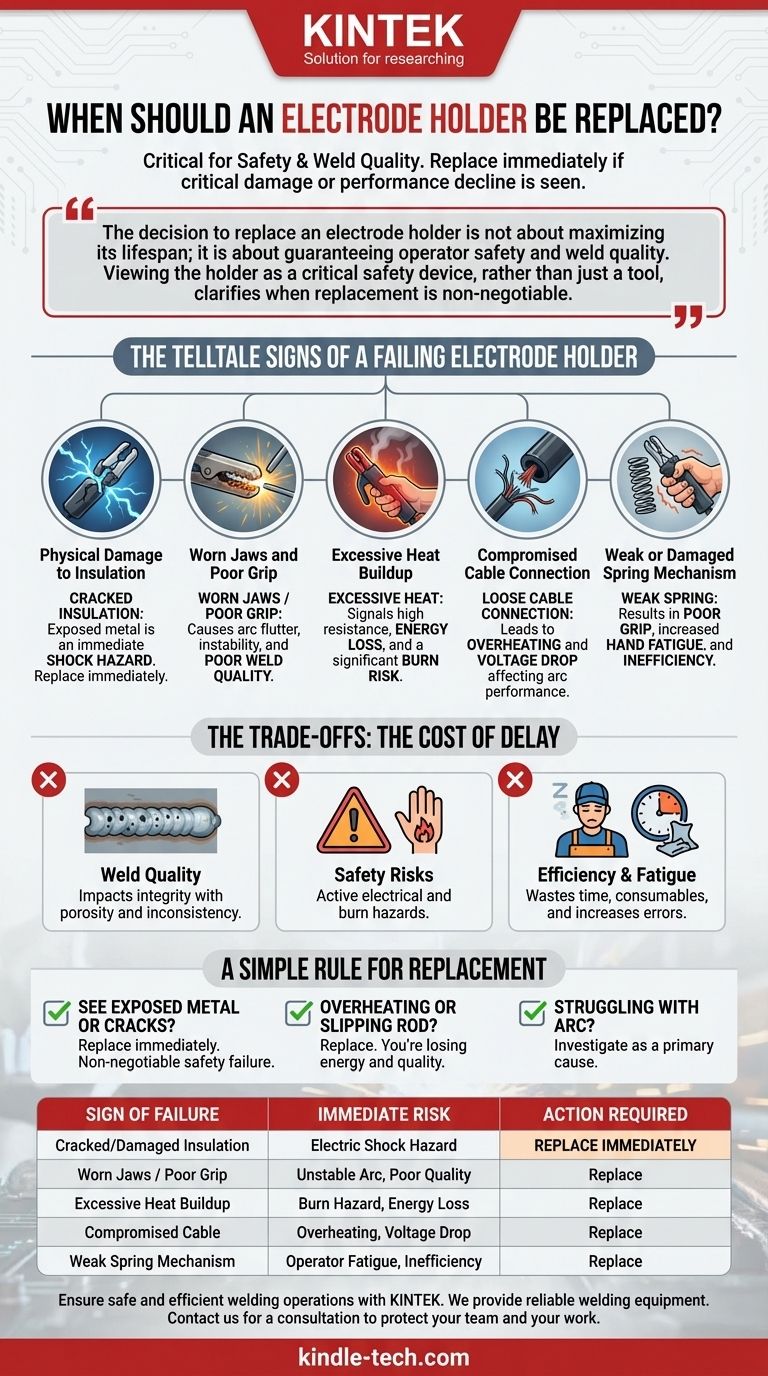

The Telltale Signs of a Failing Electrode Holder

An electrode holder is the primary point of contact between the welder, the electrical circuit, and the work. Its condition directly impacts safety, comfort, and the final weld quality. Recognizing the signs of failure is a fundamental skill.

Physical Damage to Insulation

The insulator is the most critical safety feature of the holder. It protects you from electric shock.

Any cracks, deep gouges, or missing pieces of insulation that expose the internal metal components are grounds for immediate replacement. This is a severe shock hazard that cannot be ignored.

Worn Jaws and Poor Grip

The jaws secure the welding electrode, ensuring a stable electrical connection.

Over time, the grooves in the jaws wear down. This leads to a weak grip, causing the electrode to slip or sit at an improper angle. A poor connection here creates arc flutter, instability, and inconsistent welds.

Excessive Heat Buildup

A properly functioning electrode holder should remain cool enough to handle comfortably.

If your holder becomes excessively hot during use, it signals high electrical resistance. This is most often caused by a worn-out jaw connection or a loose cable connection, wasting energy and creating a significant burn risk.

Compromised Cable Connection

The point where the welding cable enters the holder is a common failure point.

Repeated flexing can fray the cable strands, and vibrations can loosen the mechanical connection inside the handle. A loose connection here is a primary source of overheating and voltage drop, which directly affects arc performance.

Weak or Damaged Spring Mechanism

The spring provides the clamping force for the jaws.

A weak or broken spring will result in a poor grip on the electrode. It also increases the hand fatigue required to open the jaws and change rods, slowing down work and reducing operator comfort.

Understanding the Trade-offs: The Cost of Delay

Continuing to use a faulty electrode holder introduces risks that far outweigh the cost of a replacement. The trade-off is never in your favor.

The Impact on Weld Quality

A degraded holder makes it difficult to maintain a stable arc. The resulting voltage fluctuations and poor electrode contact can introduce porosity and inconsistency, compromising the integrity of the weld.

The Critical Safety Risks

This cannot be overstated. An electrode holder with damaged insulation is an active electrical hazard. Likewise, an overheating holder is a serious burn risk that can cause injury even through a welding glove.

The Effect on Efficiency and Operator Fatigue

Struggling with a holder that won't grip rods, fighting an unstable arc, or dealing with excess heat is inefficient. It wastes time, consumables, and adds to operator fatigue, which can lead to mistakes and further safety issues.

Making the Right Choice: A Simple Rule for Replacement

Treat your electrode holder as a crucial piece of safety equipment, subject to regular inspection. A simple pre-use check can prevent poor performance and serious injury.

- If you see exposed metal or cracked insulation: Replace the holder immediately. This is a non-negotiable safety failure.

- If the holder consistently overheats or the electrode slips: Replace it. You are losing energy and compromising weld quality.

- If you struggle to strike or maintain a stable arc: Investigate the holder as a primary cause after checking your other connections and ground.

Proactive replacement of a worn electrode holder is the mark of a professional who prioritizes both safety and quality.

Summary Table:

| Sign of Failure | Immediate Risk | Action Required |

|---|---|---|

| Cracked/Damaged Insulation | Electric Shock Hazard | Replace Immediately |

| Worn Jaws / Poor Grip | Unstable Arc, Poor Weld Quality | Replace |

| Excessive Heat Buildup | Burn Hazard, Energy Loss | Replace |

| Compromised Cable Connection | Overheating, Voltage Drop | Replace |

| Weak Spring Mechanism | Operator Fatigue, Inefficiency | Replace |

Ensure your welding operations are safe and efficient with the right equipment. A faulty electrode holder compromises safety, weld integrity, and productivity. KINTEK specializes in providing reliable lab and industrial equipment, including welding tools and consumables, to meet your operational needs. Don't risk it—contact us today for a consultation to find the perfect replacement and protect your team and your work.

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable XRD Sample Holders for Diverse Research Applications

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Button Battery Case for Battery Lab Applications

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- How should the PTFE electrode stand and its components be cleaned after use? A Step-by-Step Guide to Prevent Contamination

- What are the storage requirements for the PTFE electrode stand after cleaning? Preserve Purity and Equipment Longevity

- Why is high-purity PTFE selected as the sample holder for zirconium alloy corrosion tests? Gain Unmatched Data Accuracy

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity