In short, Physical Vapor Deposition (PVD) is used to apply high-performance thin film coatings onto a vast range of products. Its applications span from decorative items like jewelry and kitchen hardware to high-tech components such as semiconductor devices, aerospace parts, and durable cutting tools.

The core purpose of PVD is not about the specific item being coated, but about fundamentally changing the surface properties of the base material. It allows manufacturers to impart new characteristics like superior hardness, corrosion resistance, or specific optical qualities onto a substrate.

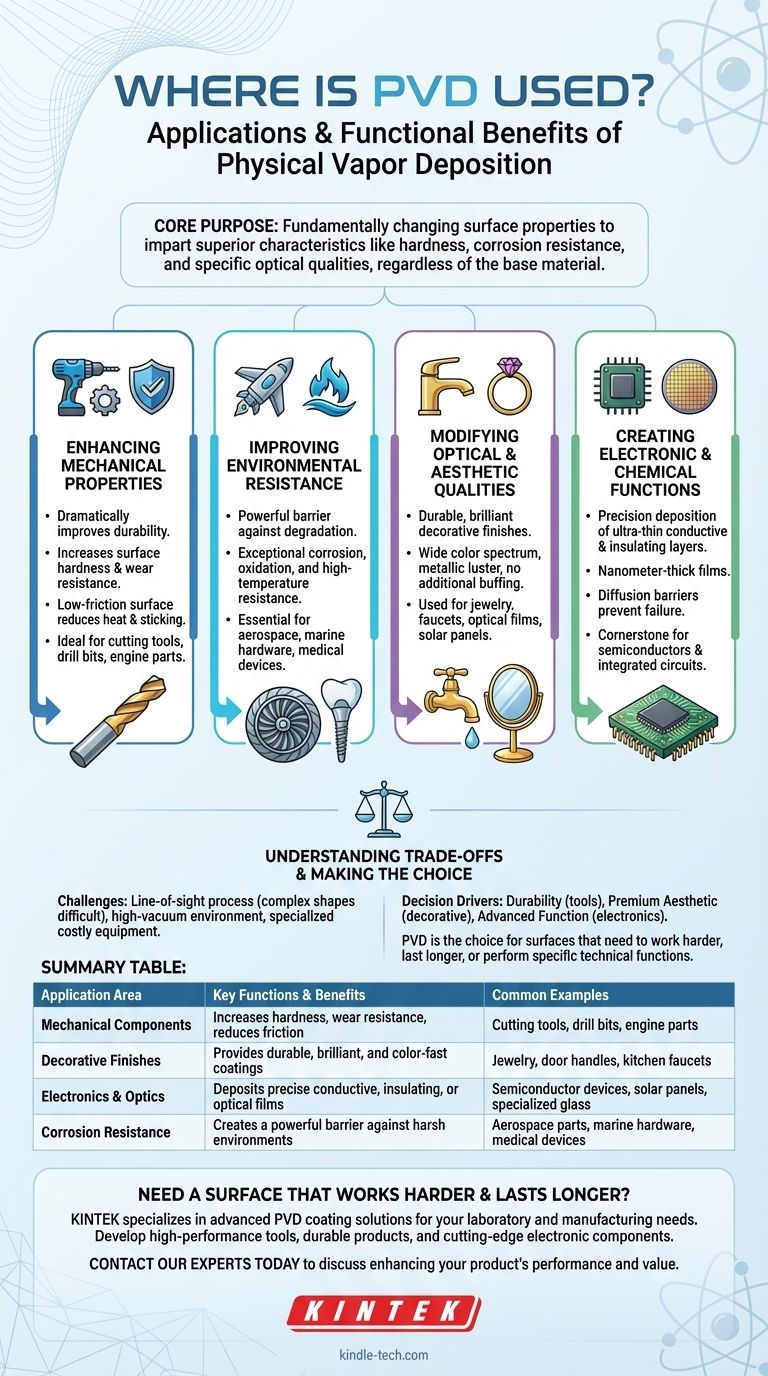

The Functional Benefits of PVD Coatings

PVD is chosen when an object's surface needs to perform better than the underlying material allows. The technology excels at depositing ultra-thin, highly-adherent films that provide specific functional advantages.

Enhancing Mechanical Properties

One of the most common uses for PVD is to dramatically improve the durability of tools and components.

By applying coatings like Titanium Nitride (TiN), PVD can significantly increase the surface hardness and wear resistance of an item. This is critical for metalworking tools, such as drill bits and milling cutters, extending their life and improving performance.

These hard coatings also create a low-friction surface, which reduces heat generation and prevents material from sticking to the tool during high-speed operations.

Improving Environmental Resistance

PVD provides a powerful barrier against environmental degradation.

Coatings can be engineered to offer exceptional corrosion and oxidation resistance. This makes PVD essential for components used in harsh environments, such as marine hardware exposed to saltwater or aerospace parts subjected to extreme temperature changes.

The process is also used to create films that are highly resistant to high temperatures and ablation, protecting critical components in engines and other demanding applications.

Modifying Optical & Aesthetic Qualities

PVD is widely used to create durable and brilliant decorative finishes.

It can deposit a wide spectrum of colors onto products like faucets, door handles, and jewelry, providing a finish that is far more durable than traditional plating. A key advantage is that the PVD film perfectly replicates the texture of the substrate, meaning a polished part will have a brilliant metallic luster without any additional buffing.

Beyond aesthetics, PVD is used to create optical films. This includes reflective coatings for mirrors and glass, as well as films for thin-film solar panels that are designed to absorb or reflect specific wavelengths of light.

Creating Electronic & Chemical Functions

The precision of PVD makes it a cornerstone technology in the electronics industry.

It is used to deposit the incredibly thin, conductive, and insulating layers required to build semiconductor devices and integrated circuits. These films can be just nanometers thick.

PVD is also used to create diffusion barriers, which prevent different materials within a complex device (like a microchip) from migrating into one another and causing failure.

Understanding the Trade-offs

While incredibly versatile, PVD is not a universal solution. It's a line-of-sight process, meaning it can be challenging to uniformly coat highly complex, three-dimensional shapes with deep recesses.

Furthermore, PVD takes place in a high-vacuum environment, which requires specialized and expensive equipment. This can make it a more costly process compared to alternatives like electroplating or painting, especially for low-value items where extreme performance is not the primary goal.

Making the Right Choice for Your Goal

The decision to use PVD should be driven by the functional requirements of your product's surface.

- If your primary focus is durability and performance: PVD is the ideal choice for creating hard, wear-resistant, and low-friction surfaces for tools and mechanical components.

- If your primary focus is a premium aesthetic: PVD provides a beautiful, long-lasting decorative finish that is significantly more resilient than paint or traditional plating.

- If your primary focus is advanced electronic or optical function: PVD is an essential technology for depositing the precise, ultra-thin films required for semiconductors, solar panels, and specialized glass.

Ultimately, PVD is the go-to technology when you need a surface that works harder, lasts longer, or performs a specific technical function that the base material cannot.

Summary Table:

| Application Area | Key Functions & Benefits | Common Examples |

|---|---|---|

| Mechanical Components | Increases hardness, wear resistance, and reduces friction. | Cutting tools, drill bits, engine parts. |

| Decorative Finishes | Provides durable, brilliant, and color-fast coatings. | Jewelry, door handles, kitchen faucets. |

| Electronics & Optics | Deposits precise conductive, insulating, or optical films. | Semiconductor devices, solar panels, specialized glass. |

| Corrosion Resistance | Creates a powerful barrier against harsh environments. | Aerospace parts, marine hardware, medical devices. |

Need a surface that works harder and lasts longer?

KINTEK specializes in advanced PVD coating solutions for your laboratory and manufacturing needs. Whether you're developing high-performance tools, durable consumer products, or cutting-edge electronic components, our expertise and equipment can help you achieve superior surface properties.

Contact our experts today to discuss how PVD technology can enhance your product's performance, durability, and value.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition