In essence, microwave sintering is primarily used for ceramics and, to a lesser extent, for specific metal powders and compounds. The technology is most effective for materials that can efficiently absorb microwave energy, including a wide range of oxides, nitrides, and carbides like aluminum oxide, silicon nitride, and zirconium oxide, as well as electronic materials like PZT piezoelectric ceramics.

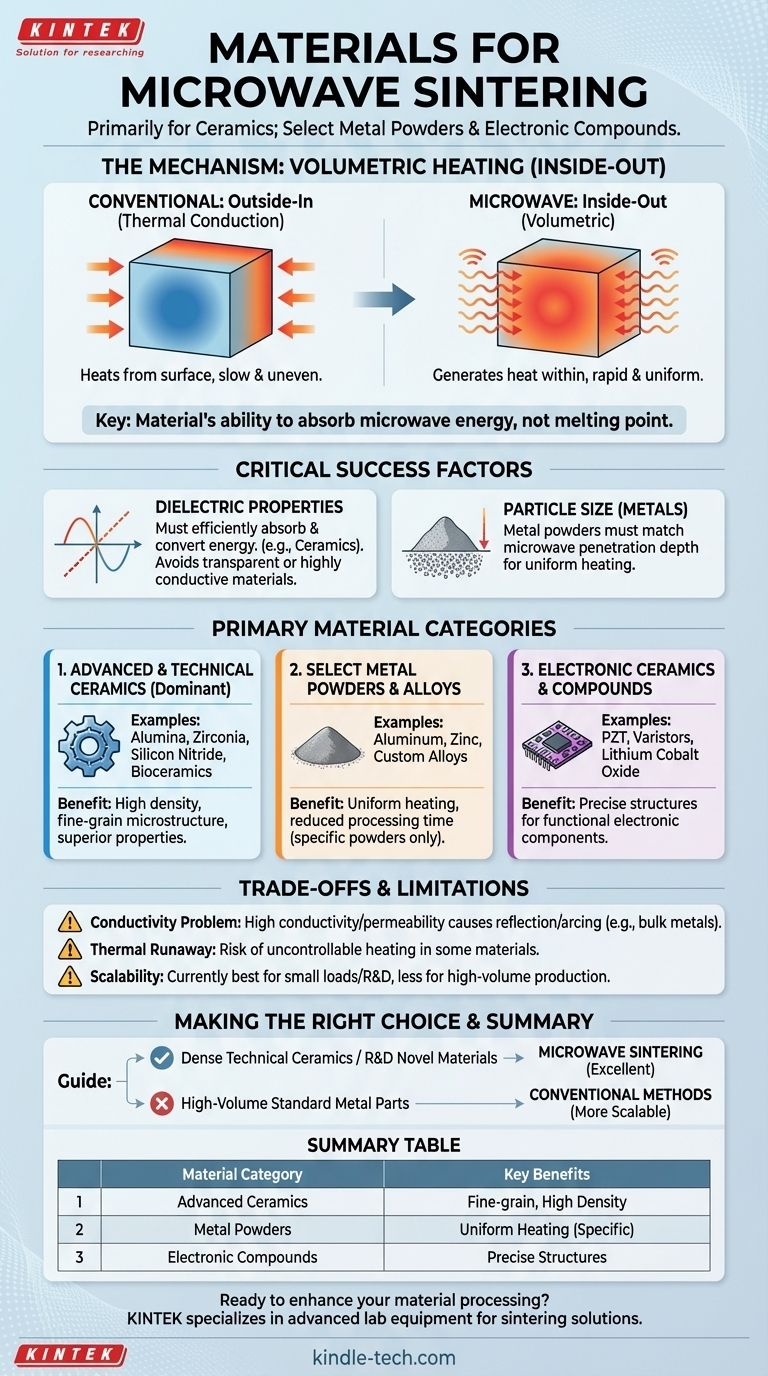

While conventional sintering heats materials from the outside-in, microwave sintering heats them volumetrically from the inside-out. This fundamental difference is why material selection is not about melting point, but about a material's ability to interact with and absorb microwave energy.

How the Process Dictates Material Choice

Microwave sintering is not a universal replacement for traditional methods. Its unique heating mechanism makes it highly suitable for some materials and impractical for others. The selection process is governed by physics, not just temperature.

The Principle of Volumetric Heating

Unlike a conventional furnace that relies on thermal conduction from external heating elements, microwave sintering uses microwave radiation to generate heat directly within the material.

This internal, or volumetric, heating leads to much faster and more uniform temperature distribution, provided the material is receptive to microwaves. This can significantly reduce processing time and energy consumption.

The Importance of Dielectric Properties

A material's suitability for microwave sintering depends on its dielectric properties—how it behaves in an electric field. Materials that can efficiently absorb microwave energy and convert it into heat are excellent candidates.

Conversely, materials that are transparent to microwaves (like some pure polymers) will not heat up, while materials that are highly conductive (like bulk metals) will reflect the microwaves, preventing them from penetrating and heating the core.

The Role of Particle Size

Microwaves can only penetrate a certain distance into a conductive material. For this reason, microwave sintering of metals requires powders with a particle size similar to the microwave penetration depth.

This ensures the energy can be absorbed throughout the powder compact rather than just at the surface, enabling uniform heating and successful densification.

Primary Material Categories for Microwave Sintering

Based on these principles, the materials prepared by microwave sintering fall into a few key categories.

Advanced and Technical Ceramics

This is the most common and successful application. The process is excellent for producing high-quality, dense ceramics with fine-grained microstructures, which enhances their mechanical properties.

Key examples include:

- Aluminum Oxide (Alumina)

- Zirconium Oxide (Zirconia)

- Silicon Nitride & Silicon Carbide

- Aluminum Nitride

- Bioceramics (where fine grain size is critical)

Select Metals and Alloys

While bulk metals are poor candidates, specific metal powders can be sintered effectively. Aluminum and zinc are notable examples. Unique alloys can also be created by mixing different metal powders.

The main challenge remains managing the high conductivity and avoiding microwave reflection.

Electronic Ceramics and Compounds

The precise and rapid heating of microwave sintering is ideal for creating functional electronic components where specific crystalline structures are essential.

Examples include:

- PZT (Lead Zirconate Titanate) piezoelectric ceramics

- Varistors

- Lithium Cobalt Oxide

- Vanadium Oxide

Understanding the Trade-offs and Limitations

While powerful, microwave sintering is not without its challenges. Understanding its limitations is crucial for successful application.

The Conductivity and Permeability Problem

As mentioned, materials with high electrical conductivity or high magnetic permeability are difficult to process. They tend to reflect microwaves, leading to inefficient heating or arcing. This is the primary reason why microwave sintering is not widely used for a broad range of metals.

Risk of Thermal Runaway

Some materials become significantly more absorbent of microwave energy as their temperature increases. This can create a feedback loop known as thermal runaway, where heating accelerates uncontrollably, potentially causing defects, melting, or damage to the equipment.

Throughput and Scalability

Most current microwave sintering systems are designed for small loads, often processing only one part at a time. This limits overall productivity and can make the process less economical for high-volume manufacturing compared to batch processing in conventional furnaces.

Making the Right Choice for Your Goal

Ultimately, the decision to use microwave sintering depends on your specific material and desired outcome.

- If your primary focus is creating dense, fine-grained technical ceramics: Microwave sintering is an excellent choice, offering superior speed and improved material properties.

- If your primary focus is high-volume production of standard metal parts: Conventional press-and-sinter or metal injection molding are almost always more scalable and cost-effective.

- If your primary focus is research and development of novel materials: The unique heating mechanism makes microwave sintering a powerful tool for processing materials that are difficult to densify with traditional methods.

Choosing the correct sintering method begins with understanding how the energy source interacts with your material.

Summary Table:

| Material Category | Key Examples | Primary Benefits |

|---|---|---|

| Advanced Ceramics | Alumina, Zirconia, Silicon Nitride | Fine-grained structure, superior density, enhanced mechanical properties |

| Metal Powders | Aluminum, Zinc, custom alloys | Uniform heating, reduced processing time for specific powders |

| Electronic Compounds | PZT, Varistors, Lithium Cobalt Oxide | Precise crystalline structures, ideal for functional electronic components |

Ready to enhance your material processing with microwave sintering?

KINTEK specializes in advanced lab equipment and consumables, including solutions for sintering advanced ceramics, metal powders, and electronic materials. Our expertise can help you achieve faster processing times, superior material density, and fine-grained microstructures.

Contact us today to discuss how our sintering solutions can meet your specific laboratory needs and drive your research or production forward.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the principle of muffle furnace in lab? Ensuring Sample Purity Through Complete Isolation

- How does a high-temperature muffle furnace contribute to the acid-thermal treatment process of carbon felt anodes?

- How does a high-temperature furnace contribute to the densification of LLZTO? Expert Sintering Guide

- Why must laboratory high-temperature sintering furnaces possess precise temperature control? Save Your Alumina Carriers

- What is the purpose of using a high-temperature annealing furnace for iron-chromium alloys? Ensure Data Accuracy

- How is a high-temperature muffle furnace utilized in RTAC for catalyst preparation? Master Thermal Shock Engineering

- What are the disadvantages of the tempering process? Understanding the Hardness vs. Toughness Trade-off

- Why is precise heating rate control critical for tungsten oxide annealing? Preserve Delicate Nanostructures