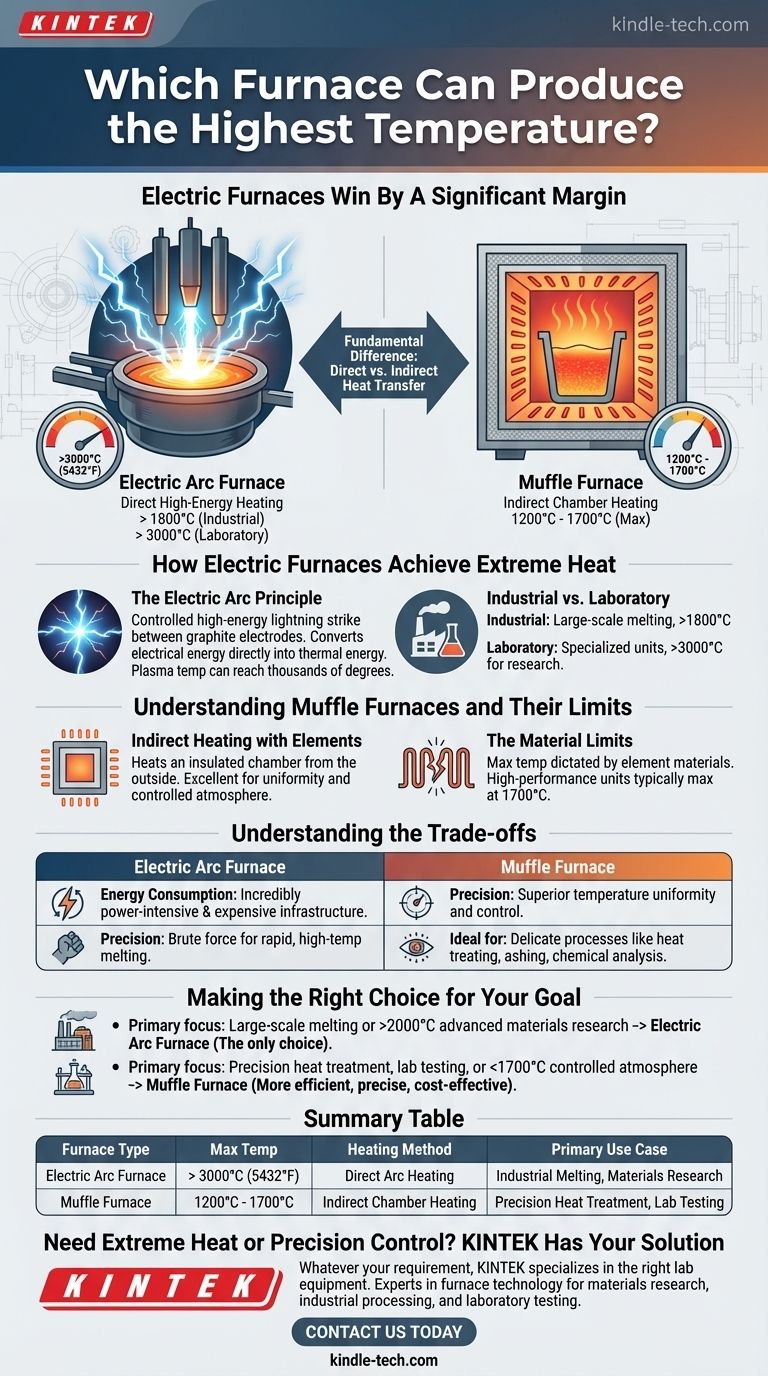

By a significant margin, the electric furnace generates the highest temperatures. Industrial electric arc furnaces routinely produce heat over 1800°C (3272°F), while specialized laboratory versions can exceed an incredible 3000°C (5432°F). This capability is rooted in its method of direct, high-energy heating.

The fundamental difference between furnaces is not just their power source, but how they transfer heat. An electric arc furnace applies energy directly to the target material, enabling vastly higher temperatures than muffle furnaces, which heat a chamber indirectly.

How Electric Furnaces Achieve Extreme Heat

The technology behind an electric furnace's immense heat is the electric arc. This is essentially a controlled, high-energy lightning strike between graphite electrodes.

The Principle of the Electric Arc

An electric arc is a plasma discharge that forms when a powerful electric current jumps a gap between two electrodes. This process converts enormous amounts of electrical energy directly into thermal energy.

The temperature within the arc itself can reach thousands of degrees Celsius, far hotter than any chemical flame. This intense heat is then transferred directly to the material being processed, such as scrap metal in a steel recycling plant.

Industrial vs. Laboratory Models

Industrial arc furnaces are designed for large-scale melting and can consistently operate above 1800°C.

Laboratory-grade arc furnaces are smaller, more specialized units. By concentrating immense power in a smaller space, they can achieve extreme temperatures exceeding 3000°C for materials research and testing.

Understanding Muffle Furnaces and Their Limits

Muffle furnaces are a cornerstone of laboratory and industrial work but operate on a completely different principle, which inherently limits their maximum temperature.

Indirect Heating with Elements

A muffle furnace works by heating a separate, insulated chamber (the "muffle") from the outside using heating elements. The heat radiates inward, creating a very uniform and controlled temperature environment.

This design is excellent for processes that require precision and a controlled atmosphere, free from contaminants produced by a direct flame or arc.

The Material Limits of Heating Elements

The maximum temperature of a muffle furnace is dictated by the materials used in its heating elements. While sources may vary, high-performance units typically max out between 1200°C and 1700°C.

The elements themselves must be rated for a higher temperature than the chamber's target. For instance, a furnace rated for 1700°C will use elements capable of withstanding 1800°C. This physical limitation of materials is the primary reason muffle furnaces cannot compete with the sheer energy of an electric arc.

Understanding the Trade-offs

Choosing a furnace is not simply about finding the highest possible temperature. The extreme heat of an electric arc furnace comes with significant operational considerations.

Energy Consumption and Cost

Electric arc furnaces are incredibly power-intensive. The infrastructure required to supply the massive electrical current they need is substantial, making them expensive to install and operate.

Precision vs. Brute Force

A muffle furnace offers superior temperature uniformity and control. Its indirect heating method is ideal for delicate processes like heat treating, ashing, or chemical analysis.

An electric arc furnace, by contrast, is a tool of brute force. Its primary goal is rapid, high-temperature melting, not subtle thermal processing.

Making the Right Choice for Your Goal

Selecting the correct furnace requires a clear understanding of your specific thermal requirements.

- If your primary focus is large-scale melting of metals or advanced materials research requiring over 2000°C: The electric arc furnace is the only technology capable of meeting these demands.

- If your primary focus is precision heat treatment, laboratory testing, or processes requiring a controlled atmosphere below 1700°C: A muffle furnace is the more efficient, precise, and cost-effective choice.

Ultimately, the best furnace is the one that provides the necessary heat for your specific application safely and efficiently.

Summary Table:

| Furnace Type | Maximum Temperature | Heating Method | Primary Use Case |

|---|---|---|---|

| Electric Arc Furnace | > 3000°C (5432°F) | Direct arc heating | Industrial melting, materials research |

| Muffle Furnace | 1200°C - 1700°C (2192°F - 3092°F) | Indirect chamber heating | Precision heat treatment, lab testing |

Need Extreme Heat or Precision Control? KINTEK Has Your Solution

Whether you require the brute-force melting power of an electric arc furnace or the precise thermal control of a muffle furnace, KINTEK specializes in providing the right lab equipment for your specific high-temperature applications. Our experts understand the critical differences in furnace technology and can help you select the perfect system for materials research, industrial processing, or laboratory testing.

Contact us today to discuss your project requirements and discover how KINTEK's furnace solutions can enhance your research capabilities and operational efficiency. Get in touch with our technical team now for personalized recommendations and pricing.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why Use a Quartz Tube Reactor for Y-Ti-O Phase Transformations? Achieve Absolute Purity and Precision Control

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.