For melting scrap metal, the most effective and modern solution is typically an electric induction furnace. This technology uses a high-frequency magnetic field to heat a graphite crucible, which then melts the metal quickly and cleanly. Its speed and efficiency surpass many traditional furnace types, making it the superior choice for a wide range of applications, from small-scale work to industrial processing.

The core decision is not about finding a single "best" furnace, but about understanding why the induction heating method is uniquely suited for scrap. It offers unparalleled speed, control, and efficiency by heating the container—the crucible—rather than relying on unpredictable heating of the scrap itself.

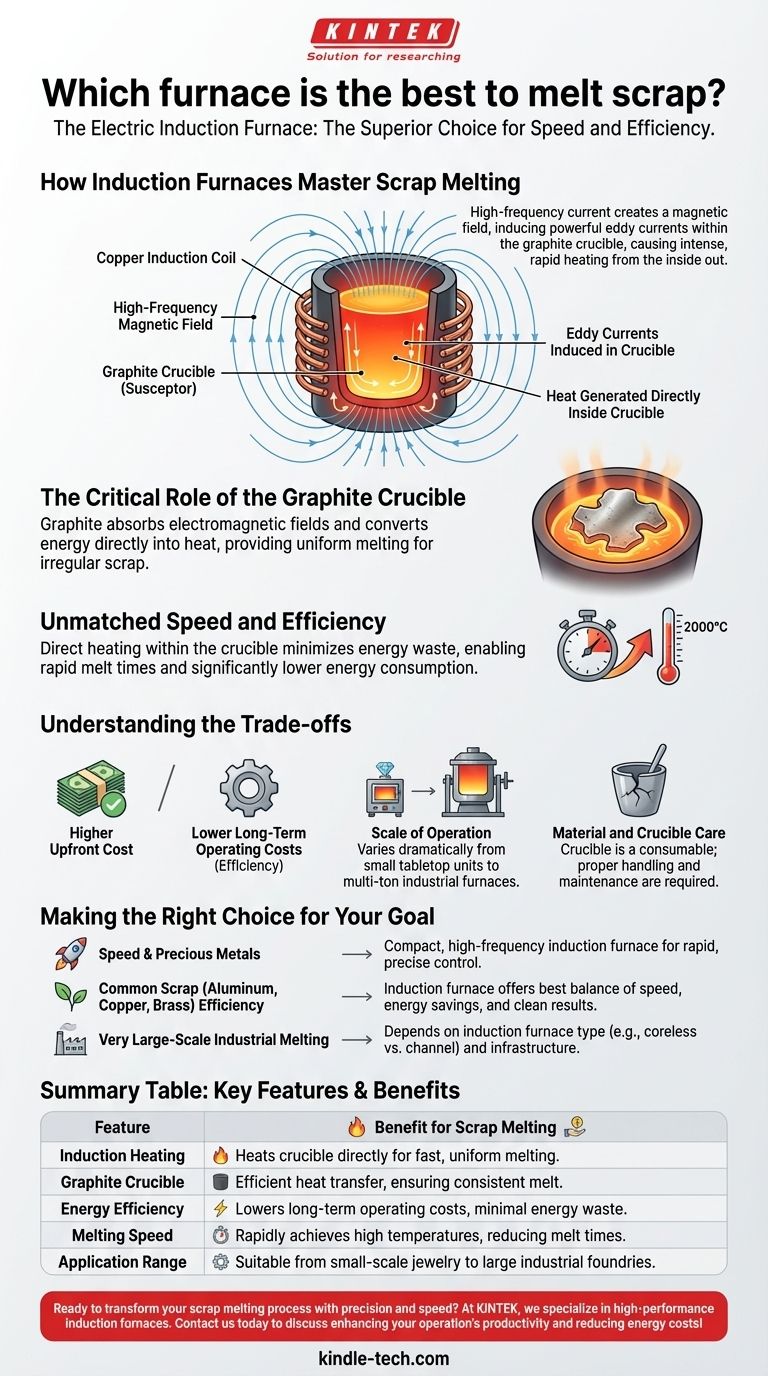

How Induction Furnaces Master Scrap Melting

To understand why induction furnaces are so effective, we must look at their core principle. They do not use external flames or heating elements that slowly transfer heat to the metal.

The Principle of Induction Heating

An induction furnace works by passing a high-frequency electric current through a copper coil. This generates a powerful and rapidly changing magnetic field around the coil.

When a graphite crucible is placed inside this field, the magnetic energy induces powerful electrical currents—known as eddy currents—within the graphite itself.

The graphite's natural resistance to these currents causes it to heat up intensely and rapidly. The heat is generated inside the crucible wall, not applied from the outside.

The Critical Role of the Graphite Crucible

The graphite crucible is the heart of the system. Graphite is an ideal material because it is a susceptor—it is excellent at absorbing electromagnetic fields and converting that energy directly into heat.

This method provides an enormous advantage for melting scrap. Irregularly shaped pieces or mixed metals often heat unevenly with other methods.

By heating the crucible, the system creates a uniformly hot container that melts the contents through direct contact and radiant heat. This ensures a smooth, controlled, and consistent melt regardless of the scrap's form.

Unmatched Speed and Efficiency

This direct method of generating heat within the crucible is incredibly efficient. Very little energy is wasted heating the surrounding air or the furnace body.

This is why some specialized units, like platinum melting furnaces, can reach extreme temperatures (over 2000°C) in just a few minutes. For common scrap metals like aluminum, brass, or steel, this translates to significantly faster melt times and lower energy consumption.

Understanding the Trade-offs

While highly effective, an induction furnace is not the only option, and it's essential to understand its context.

Upfront Cost vs. Operating Efficiency

Induction furnaces generally have a higher initial purchase price compared to simpler gas-fired or resistance furnaces.

However, their high energy efficiency and rapid melting cycles often result in lower long-term operating costs, especially in a production environment where time and energy consumption are critical factors.

Scale of Operation

The "best" furnace is highly dependent on your scale. A small tabletop induction furnace for a jeweler is a vastly different piece of equipment from a multi-ton induction furnace used in a foundry.

The core technology is the same, but the power supply, cooling systems, and material handling requirements scale dramatically.

Material and Crucible Care

The graphite crucible is a consumable item. It will degrade over time with repeated heating and cooling cycles and exposure to molten metal and oxygen.

Proper handling and maintenance are required, and the cost of crucible replacement should be factored into your operational budget. Using tools like a graphite stirring rod, as mentioned, helps preserve the crucible's integrity.

Making the Right Choice for Your Goal

To select the right furnace, align the technology's strengths with the specific demands of your task.

- If your primary focus is speed and precious metals: A compact, high-frequency electric induction furnace is unmatched for its rapid heating and precise temperature control.

- If your primary focus is melting common scrap (aluminum, copper, brass) with high efficiency: An induction furnace offers the best balance of speed, energy savings, and clean melting for consistent results.

- If your primary focus is very large-scale, industrial melting: The decision expands to different types of induction furnaces (e.g., coreless vs. channel), requiring a detailed analysis of power infrastructure and workflow.

By focusing on the clean efficiency of induction technology, you can select a furnace that delivers precise, rapid, and repeatable results for your scrap melting operation.

Summary Table:

| Feature | Benefit for Scrap Melting |

|---|---|

| Induction Heating | Heats the crucible directly for fast, uniform melting of irregular scrap. |

| Graphite Crucible | Acts as a susceptor for efficient heat transfer, ensuring a consistent melt. |

| Energy Efficiency | Lowers long-term operating costs with minimal energy waste. |

| Melting Speed | Achieves high temperatures rapidly, significantly reducing melt times. |

| Application Range | Suitable for small-scale jewelry work to large-scale industrial foundries. |

Ready to transform your scrap melting process with precision and speed?

At KINTEK, we specialize in providing high-performance lab equipment, including state-of-the-art induction furnaces designed for efficiency and reliability. Whether you're processing precious metals or common scrap like aluminum and brass, our solutions are tailored to meet your specific laboratory needs.

Contact us today to discuss how our induction furnaces can enhance your operation's productivity and reduce your energy costs!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys