For achieving the highest possible hardness in steel, the most effective process is quenching. This involves heating the steel to a very high temperature (typically over 900°C) and then cooling it with extreme rapidity. This rapid cooling, or quenching, traps the steel's internal structure in a very hard, brittle state.

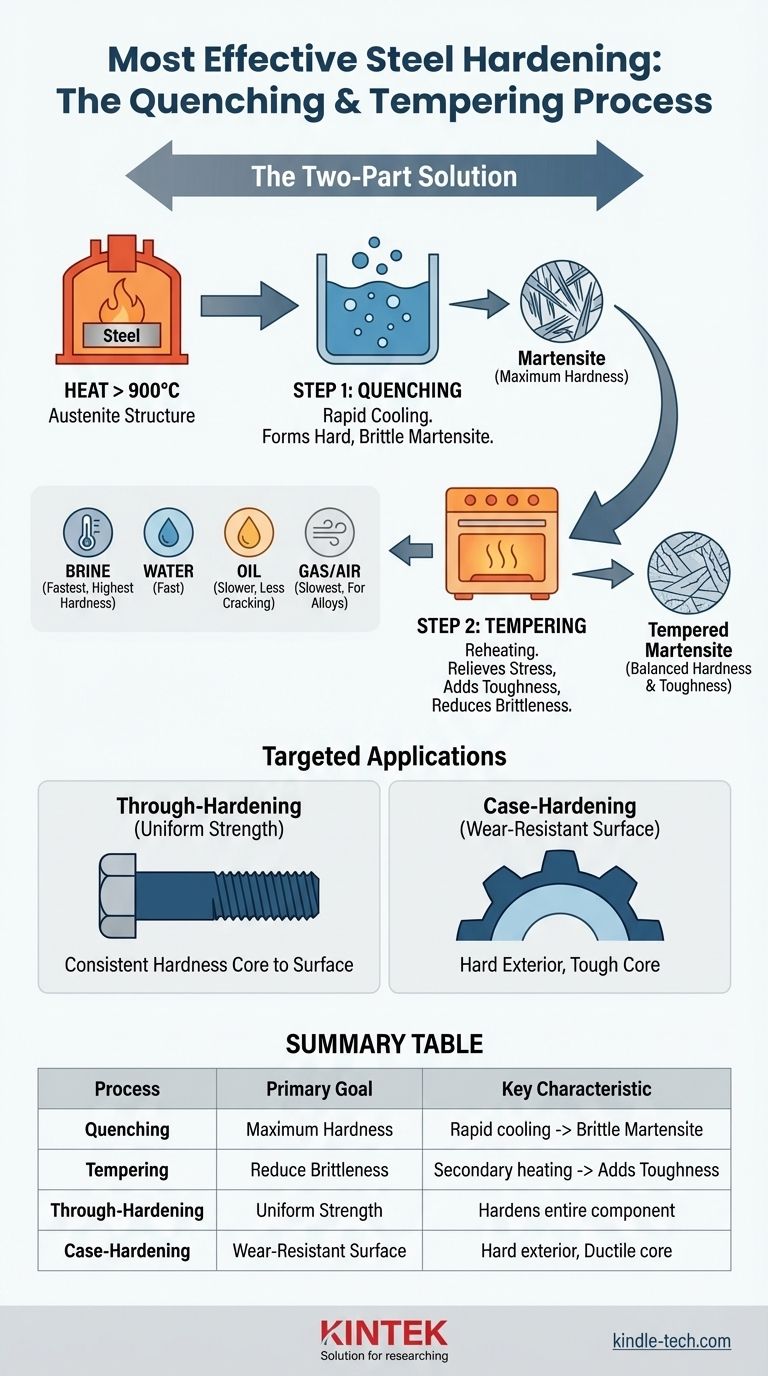

The most effective method for hardening steel isn't a single step, but a two-part process: quenching for maximum hardness, followed by tempering to reduce brittleness and add necessary toughness. The right approach depends entirely on whether you need the entire part to be hard or just the surface.

The Fundamental Principle: How Hardening Works

To understand hardening, you must see it as a process of controlled transformation. We are fundamentally changing the steel's internal crystalline structure to achieve desired mechanical properties.

The Critical Heating Phase

The journey to hardness begins with heat. The steel is heated above its "upper critical temperature," a point where its internal crystal structure changes into a form called austenite, which can dissolve carbon.

Without reaching this temperature, a full and uniform hardening is impossible to achieve.

The Quenching Transformation

Once the steel is fully austenitic, it is rapidly cooled or "quenched." This sudden temperature drop doesn't give the crystal structure time to revert to its softer, normal state.

Instead, it forces the carbon into a highly strained, needle-like structure called martensite. It is the formation of martensite that is directly responsible for the steel's dramatic increase in hardness and strength.

The Role of Quenching Media

The speed of cooling is the most critical variable in this process, and it is controlled by the quenching medium.

- Brine (salt water) offers the fastest cooling rate, leading to the highest potential hardness but also the greatest risk of distortion or cracking.

- Water is slightly less severe than brine but still provides a very rapid quench for high hardness.

- Oil cools much more slowly, reducing the risk of cracking and making it suitable for more complex shapes or certain alloy steels.

- Gas or air provides the slowest quench, typically used for specific high-alloy tool steels that harden effectively with less thermal shock.

Through-Hardening vs. Case-Hardening

While quenching is the core mechanism, its application can be targeted in two distinct ways, depending on the component's purpose.

Through-Hardening: Uniform Strength

Through-hardening, often called "neutral hardening," applies the quench and temper process to the entire component.

The goal is to achieve a consistent level of hardness and strength from the surface all the way to the core. This is essential for parts that experience high stress throughout their volume, such as structural bolts or springs.

Case-Hardening: A Wear-Resistant Surface

Case-hardening, which includes processes like carburising, is fundamentally different. It hardens only the outer surface, or "case," of the steel.

This creates a part with two distinct advantages: a very hard, wear-resistant exterior and a softer, more ductile, and tougher core. This is ideal for components like gears, which need to resist surface wear while also absorbing shock without fracturing.

Understanding the Critical Trade-offs

Achieving hardness is never without consequences. The most effective engineers and technicians understand the inherent compromises involved in heat treatment.

Hardness vs. Brittleness

The martensitic structure created by quenching is extremely hard, but it is also very brittle, much like glass. A fully quenched, untempered steel part is often too fragile for any practical application and can shatter under sharp impact.

The Necessity of Tempering

This is why quenching is almost always followed by tempering. Tempering is a secondary heating process, done at a much lower temperature, that relieves the internal stresses within the martensite.

This process reduces some of the hardness but, crucially, it removes the extreme brittleness and adds toughness—the ability to deform or absorb energy without fracturing. By carefully controlling the tempering temperature, a precise balance of hardness and toughness can be achieved.

The Risk of Distortion

Rapidly cooling a part from over 900°C is a violent thermal process. This shock can cause the component to warp, distort, or in the worst cases, crack. The choice of quenching medium and the geometry of the part are critical factors in managing this risk.

Making the Right Choice for Your Application

The "most effective" process is the one that best matches the final requirements of the component.

- If your primary focus is maximum strength and hardness throughout the entire component: A through-hardening process of quenching followed by a carefully controlled temper is the correct approach.

- If your primary focus is a wear-resistant surface with a shock-absorbent, tougher core: A case-hardening process is the superior and more effective choice.

Ultimately, selecting a heat treatment is about achieving the optimal balance of properties, transforming a simple piece of steel into a component engineered for performance.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Quenching | Maximum Hardness | Rapid cooling creates hard, brittle martensite. |

| Tempering | Reduce Brittleness | Secondary heating adds toughness and relieves stress. |

| Through-Hardening | Uniform Strength | Hardens the entire component for high-stress applications. |

| Case-Hardening | Wear-Resistant Surface | Hard exterior with a tough, ductile core (e.g., for gears). |

Ready to Harden Your Steel Components with Precision?

Choosing the right heat treatment is critical for performance and longevity. KINTEK specializes in lab equipment and consumables for material testing and analysis, helping you perfect processes like quenching and tempering. Our solutions ensure you achieve the perfect balance of hardness and toughness for your specific application.

Contact us today via our [#ContactForm] to discuss how we can support your laboratory's material science needs and help you engineer components for superior performance.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What materials are used in a vacuum furnace? Selecting the Right Hot Zone for Your Process

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing