The sintering process is defined by its remarkable material versatility. It is not limited to a single substance but is applied to a wide array of powdered materials, most commonly metals and ceramics. Key examples include metal powders like stainless steel, aluminum, copper, and titanium alloys, as well as ceramic powders such as aluminum oxide and zirconium oxide.

The crucial insight is that sintering is not defined by a specific material, but by a process that can fuse powdered particles of nearly any substance into a solid mass without fully melting them. This core principle is what makes it applicable to such a diverse range of materials.

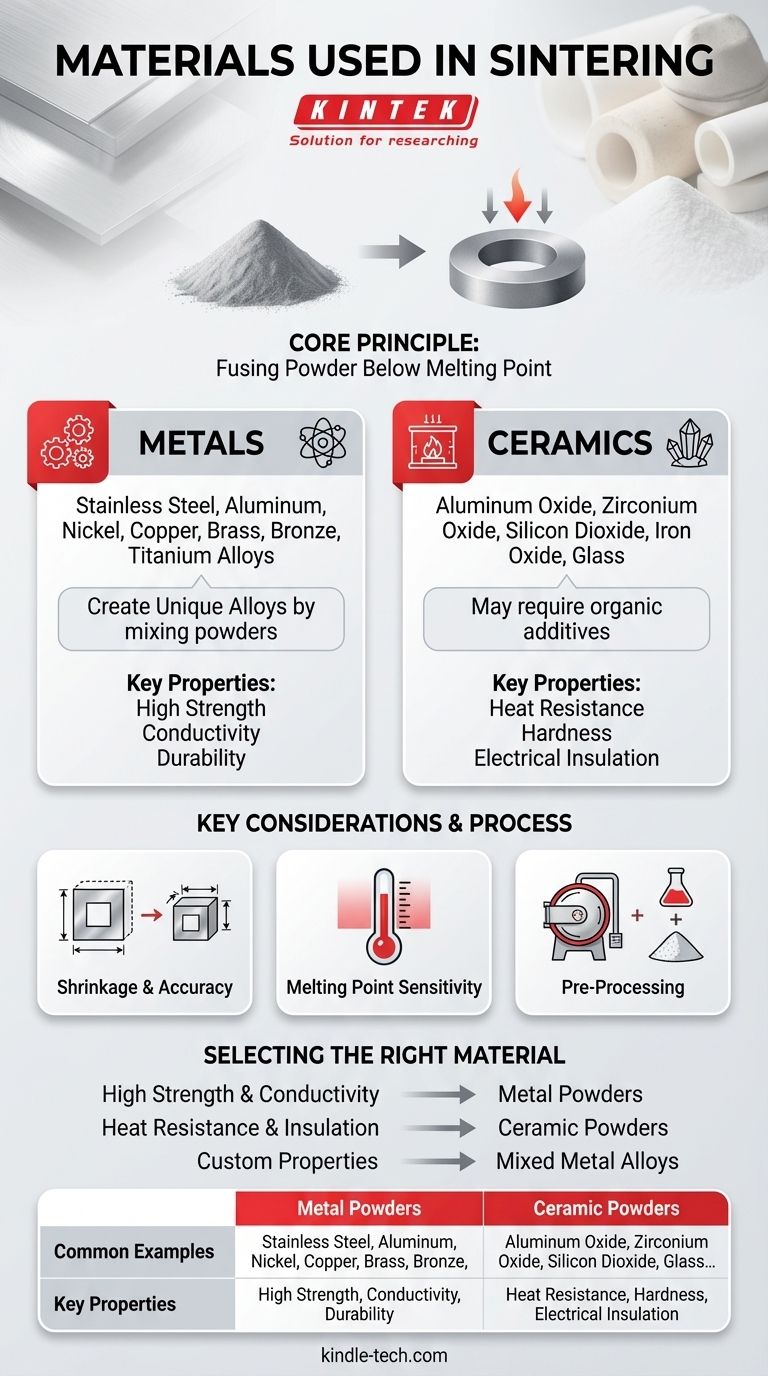

The Two Primary Material Families in Sintering

Sintering's flexibility stems from its ability to handle materials with vastly different properties, as long as they can be formed into a powder. The two dominant categories are metals and ceramics.

Metal Powders and Alloys

Metals are the most common materials used in sintering. This process is ideal for creating strong, complex metal parts with high consistency.

Commonly sintered metals include stainless steel, aluminum, nickel, copper, brass, bronze, and titanium alloys.

A significant advantage of sintering is the ability to mix different metal powders before the process begins. This allows for the creation of unique alloys with tailored properties that meet very specific engineering requirements.

Advanced Ceramic Powders

Sintering is also a fundamental process in the manufacturing of advanced ceramic components, which are valued for their hardness, heat resistance, and insulating properties.

Materials in this category include glass, aluminum oxide, zirconium oxide, silicon dioxide, and iron oxide.

Unlike metals, some ceramic raw materials may require the addition of organic additives or coupling agents in the pre-sintering stage to help the particles bond effectively.

How Sintering Accommodates Different Materials

The true power of sintering lies in its foundational process, which is adaptable to the unique characteristics of each material. It relies on a few universal principles.

The Core Principle: Fusing Below Melting Point

The defining step is heating the compressed powder to a temperature just below its melting point.

At this temperature, the atoms at the surface of the particles become mobile and diffuse across the boundaries of adjacent particles, creating solid bridges. This fuses the material into a single, densified mass without it ever becoming a liquid.

This principle is why materials with very different melting points, from aluminum to tungsten, can all be processed via sintering.

Powder as the Universal Starting Point

Regardless of the material, the process always begins with a powder. This powder is first placed into a mold or die.

It is then compacted under high pressure to form a "green part," which has the desired shape but is still fragile. This compressed shape is what goes into the furnace for heating.

Understanding the Trade-offs

While incredibly versatile, the sintering process has material-specific considerations that must be managed for a successful outcome.

Shrinkage and Dimensional Accuracy

As the powdered particles fuse and the gaps between them close, the part inevitably shrinks.

This shrinkage is predictable but must be carefully calculated and accounted for in the initial design of the mold and the green part to achieve the final desired dimensions.

Melting Point Sensitivity

The entire process hinges on precise temperature control.

Heating the material too little will result in a weak, porous part. Overheating, even slightly, can cause the material to melt, ruining the part and defeating the purpose of the process.

Pre-Processing Requirements

Not all powders are immediately ready for sintering. As noted with some ceramics, additives may be required to ensure proper binding.

Furthermore, many sintering processes must take place in a controlled atmosphere or vacuum furnace to prevent oxidation, especially when working with reactive metals like titanium.

Selecting the Right Material for Your Application

Your choice of material is dictated entirely by the final properties your component needs. The sintering process provides a reliable path to achieve those properties.

- If your primary focus is high strength and conductivity: Your best choice will be metal powders such as stainless steel, copper, bronze, or titanium alloys.

- If your primary focus is heat resistance and electrical insulation: You should select advanced ceramic powders like aluminum oxide or zirconium oxide.

- If your primary focus is creating custom properties: The best approach is to explore mixing different metal powders to create a unique alloy tailored to your specific performance needs.

Ultimately, the power of sintering lies in using a universal process to transform a vast range of powdered materials into precisely engineered components.

Summary Table:

| Material Category | Common Examples | Key Properties |

|---|---|---|

| Metal Powders | Stainless Steel, Aluminum, Copper, Titanium Alloys | High Strength, Conductivity, Durability |

| Ceramic Powders | Aluminum Oxide, Zirconium Oxide, Silicon Dioxide | Heat Resistance, Hardness, Electrical Insulation |

Ready to transform powdered materials into high-performance components? KINTEK specializes in providing the precise lab equipment and consumables needed for successful sintering processes. Whether you're working with advanced metals or technical ceramics, our expertise ensures you achieve the desired strength, density, and dimensional accuracy. Contact our experts today to discuss your specific material and application requirements!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the process of sputtering in a vacuum? A Guide to High-Purity Thin Film Deposition

- Should I get a single stage or two stage furnace? Make the Smart Choice for Your Home Comfort

- Does pressure depend on shape? Understanding When Shape Matters in Physics

- What is the principle of vacuum evaporation? Unlock Precise Coating and Purification

- Which of the following are methods used to deposit thin films? A Guide to PVD, CVD & More

- How is a crucible used in the crucible? Unpacking Arthur Miller's Powerful Metaphor

- What are the products of sintering? Achieve Durable, Complex Parts from Powder

- What is the physics of sputtering? A Guide to Thin Film Deposition by Momentum Transfer