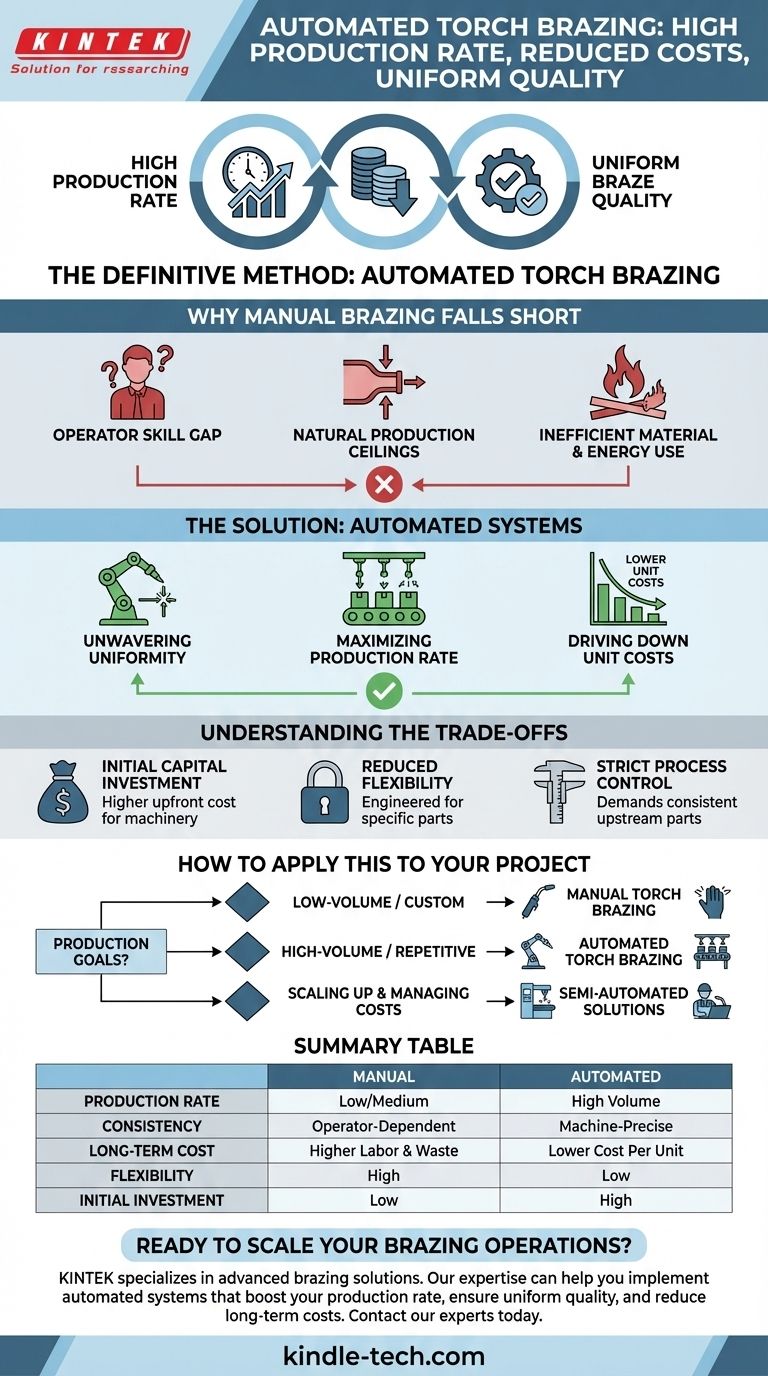

For torch brazing, the definitive method for achieving a high production rate, reduced costs, and uniform quality is automated torch brazing. This approach removes the variability and speed limitations of a human operator by using machinery to precisely control every step of the process, from part handling to heat application and filler metal dispensing.

The core challenge in scaling any brazing operation is overcoming the trade-off between speed and quality. Automated torch brazing resolves this by replacing operator-dependent skill with machine precision, making it the superior choice for high-volume manufacturing.

Why Manual Brazing Falls Short in High-Volume Production

While manual torch brazing is flexible and effective for repairs or small-batch work, it inherently struggles to meet the demands of modern manufacturing for three key reasons.

The Operator Skill Gap

The quality of a manual braze joint is entirely dependent on the skill and consistency of the operator. This introduces significant variability between different workers and even with the same worker over a long shift.

Natural Production Ceilings

A human operator can only work on one joint at a time. This creates a hard limit on throughput that cannot be overcome without adding more labor, which dramatically increases costs.

Inefficient Material and Energy Use

Manual heating can be inconsistent, leading to part overheating, distortion, or an incomplete braze. Likewise, manual application of filler metal often results in waste and requires more extensive post-braze cleaning, adding to the cost per part.

The Solution: Automated Torch Brazing Systems

Automated systems integrate the brazing process into a production line, often using a rotary indexing table or a conveyor. This systematic approach is what unlocks superior performance.

Achieving Unwavering Uniformity

Automation ensures every single part is subjected to the exact same process. Torches are fixed in optimal positions, heat is applied for a precise duration, and a metered amount of filler metal is dispensed every time, resulting in highly uniform, repeatable joints.

Maximizing Production Rate

An automated system can be designed with multiple stations to heat, braze, and cool parts simultaneously. By moving parts continuously through this cycle, production rates can be increased by an order of magnitude compared to manual methods.

Driving Down Unit Costs

While the initial investment is higher, automation reduces costs significantly over the long term. This is achieved through lower labor costs, a dramatic reduction in rejected parts, more efficient use of filler metal and fuel gas, and higher overall throughput.

Understanding the Trade-offs

Adopting automation is a strategic decision that involves clear trade-offs. It is not the right solution for every scenario.

The Initial Capital Investment

The primary barrier to automation is the upfront cost of designing, building, and integrating the machinery. This investment is typically only justifiable for high-volume production where the return can be realized.

Reduced Flexibility for Part Design

Automated systems are often engineered to produce a specific part or a family of very similar parts. Changing the part design may require significant and costly retooling, whereas a manual operator can adapt almost instantly.

The Need for Strict Process Control

Automation demands consistency in the parts being fed into it. The system is calibrated for specific joint clearances, surface cleanliness, and part dimensions. Any deviation in these upstream processes can compromise the quality of the automated braze.

How to Apply This to Your Project

Choosing the right approach requires aligning your method with your specific production goals.

- If your primary focus is low-volume production or custom fabrication: Manual torch brazing remains the most practical and cost-effective choice due to its flexibility and low initial cost.

- If your primary focus is high-volume, repetitive manufacturing: Automated torch brazing is the only method that can simultaneously deliver high speed, exceptional uniformity, and the lowest long-term cost per unit.

- If you are scaling up but need to manage costs: Consider semi-automated solutions where an operator loads parts into a machine that then performs a repeatable, automated heating cycle.

By correctly matching your brazing technology to your production volume, you can build a process that is both efficient and reliable.

Summary Table:

| Feature | Manual Torch Brazing | Automated Torch Brazing |

|---|---|---|

| Production Rate | Low to Medium | High Volume |

| Consistency | Operator-Dependent | Machine-Precise |

| Long-Term Cost | Higher Labor & Waste | Lower Cost Per Unit |

| Flexibility | High (Ideal for Repairs) | Low (Fixed Part Designs) |

| Initial Investment | Low | High |

Ready to scale your brazing operations with precision and efficiency? KINTEK specializes in laboratory and production equipment, including advanced brazing solutions. Our expertise can help you implement automated systems that boost your production rate, ensure uniform braze quality, and reduce long-term costs. Contact our experts today to discuss how we can tailor a solution for your high-volume manufacturing needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam