Hydraulic presses are foundational tools across countless industries, utilized by anyone needing to generate immense force in a controlled manner. From industrial manufacturing and metalworking shops to scientific laboratories and recycling plants, their applications are centered on shaping, molding, compressing, and assembling materials that would be impossible to manage by other means.

At its core, a hydraulic press is the go-to solution for any operation requiring massive, controllable force in a compact and cost-effective package. Its power comes not from complex gearing but from a simple physics principle, making it uniquely suited for shaping, molding, and compressing the toughest materials.

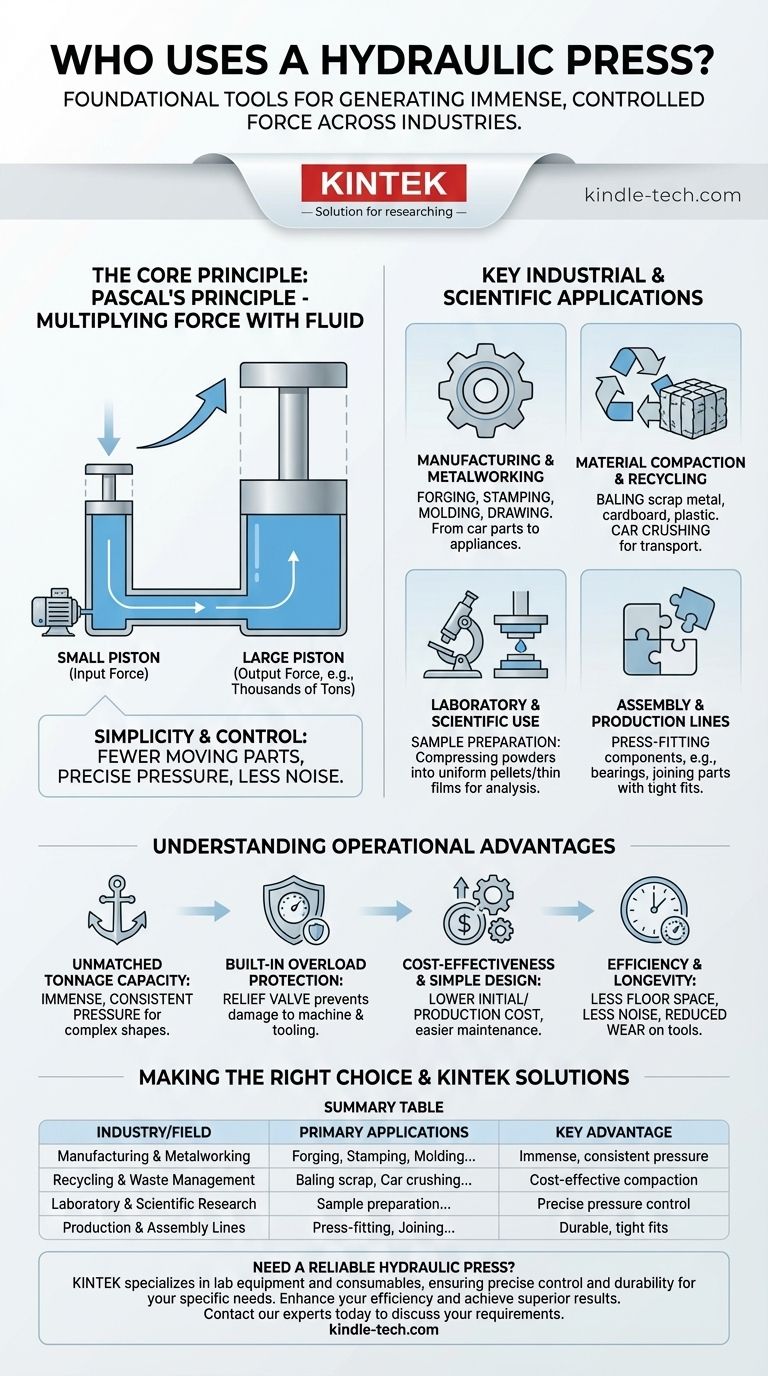

The Core Principle: Why a Hydraulic Press is So Powerful

To understand who uses a hydraulic press, you must first understand why it's so effective. The machine's power is derived from a concept known as Pascal's Principle.

Multiplying Force with Fluid

A hydraulic press uses a liquid (typically oil) to transmit force. A small amount of pressure applied to a small piston in a sealed system is transferred through the incompressible fluid, where it acts on a much larger piston.

This process multiplies the initial force exponentially, allowing a small motor to generate thousands of tons of pressure.

Simplicity and Control

Unlike mechanical presses that rely on flywheels and clutches, a hydraulic press has a relatively simple design with fewer moving parts. This results in a machine that is easier to maintain, less noisy, and offers precise control over the amount of pressure applied.

Key Industrial and Scientific Applications

The ability to generate and control massive force makes the hydraulic press indispensable across a wide range of fields.

Manufacturing and Metalworking

This is the most common domain for hydraulic presses. They are used for forging, stamping, molding, and drawing metal into specific shapes. Operations from car part manufacturing (body panels, brake pads) to appliance production rely on them.

Material Compaction and Recycling

Waste management and recycling facilities use large-scale hydraulic presses for baling materials like scrap metal, cardboard, and plastic. This also includes "scrapping" operations, such as crushing junked cars to a fraction of their original size for easier transport and processing.

Laboratory and Scientific Use

In a more precise application, laboratories use hydraulic presses for sample preparation. As noted in research and quality control, a press is used to compress powdered materials into uniform pellets or thin films, which are essential for various types of analytical testing.

Assembly and Production Lines

Many production lines use smaller hydraulic presses for press-fitting components together. This includes tasks like inserting bearings into housings or joining parts with an extremely tight, durable fit.

Understanding the Operational Advantages

The choice to use a hydraulic press over other types, like a mechanical press, comes down to a clear set of operational and financial benefits.

Unmatched Tonnage Capacity

The primary advantage is the ability to generate immense, consistent pressure. The force is applied evenly throughout the entire piston stroke, which is critical for forming complex shapes or working with high-strength materials.

Built-in Overload Protection

Because pressure is managed by a relief valve, a hydraulic press has built-in overload protection. If the force exceeds a set limit, the valve opens, preventing damage to the machine and the tooling. This is a significant safety and maintenance advantage.

Cost-Effectiveness and Simple Design

Hydraulic presses generally have a lower initial and production cost compared to mechanical presses of similar tonnage. Their design is simpler with fewer parts, which also leads to reduced mold costs and easier maintenance over the machine's lifespan.

Efficiency and Longevity

These presses require less floor space than their mechanical counterparts and operate with significantly less noise. The smooth, controlled application of force also reduces wear and tear, contributing to a longer lifespan for the tools and dies being used.

Making the Right Choice for Your Goal

Understanding these applications and benefits helps clarify when a hydraulic press is the correct tool for the job.

- If your primary focus is maximum force and precise control: A hydraulic press is the superior choice for high-tonnage applications like deep-drawing metal, forging, or complex molding.

- If your primary focus is high-speed, repetitive stamping: A mechanical press might be more suitable, as it often provides faster cycle times for simpler, high-volume production runs.

- If your primary focus is preparing consistent scientific samples: A specialized, low-tonnage laboratory hydraulic press offers the exact pressure control needed for reliable analytical results.

Ultimately, the hydraulic press is a testament to how a simple physical principle can be leveraged to achieve extraordinary industrial and scientific power.

Summary Table:

| Industry/Field | Primary Applications | Key Advantage |

|---|---|---|

| Manufacturing & Metalworking | Forging, Stamping, Molding, Drawing | Immense, consistent pressure for shaping metal |

| Recycling & Waste Management | Baling scrap metal, cardboard, plastic; Car crushing | Cost-effective compaction for transport |

| Laboratory & Scientific Research | Sample preparation (pellets, thin films) | Precise pressure control for analytical testing |

| Production & Assembly Lines | Press-fitting bearings, joining components | Durable, tight fits with controlled force |

Need a Reliable Hydraulic Press for Your Operations?

Whether you are shaping metal in a manufacturing plant, compacting materials in a recycling facility, or preparing precise samples in a laboratory, the right hydraulic press is critical to your success.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise ensures you get a hydraulic press that delivers the precise control, immense force, and durability your specific application demands.

Let us help you enhance your efficiency and achieve superior results.

Contact our experts today to discuss your requirements and find the perfect hydraulic press solution for your laboratory or industrial process.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples