To achieve a high-performance coating, you must first create an environment of near-perfect emptiness. A vacuum is essential for coating processes because it removes air and other gas particles from the chamber. These particles would otherwise interfere with the coating process, colliding with the coating material and preventing it from forming a pure, dense, and strongly bonded layer on the target surface.

The fundamental purpose of a vacuum in coating is not just to remove air, but to create an ultra-clean, controlled pathway. This ensures the coating material travels from its source to the substrate without collision or contamination, which is the secret to achieving superior adhesion, purity, and performance.

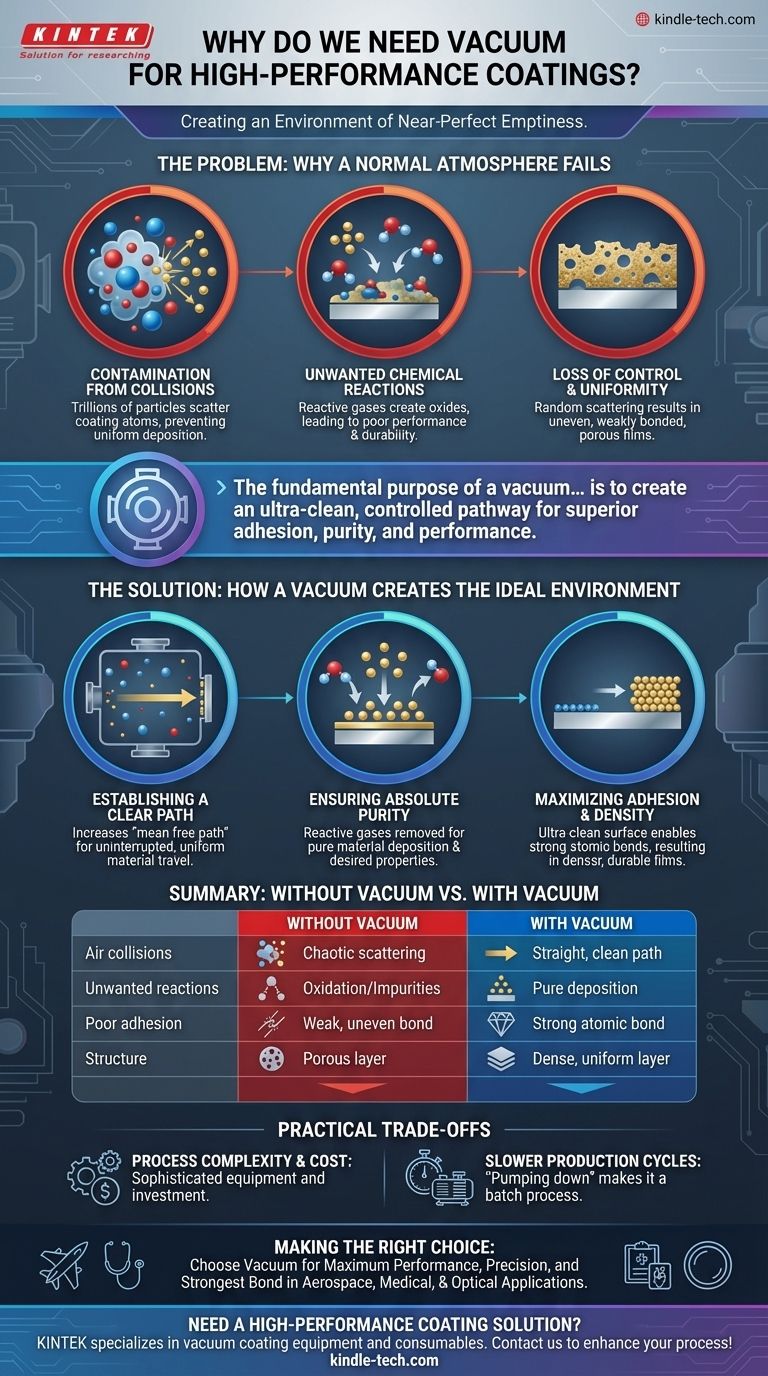

The Problem with Air: Why a Normal Atmosphere Fails

Coating at the nanoscale is a process of precision. Attempting this in a normal atmospheric environment introduces uncontrollable variables that actively work against the goal of a perfect finish.

Contamination from Collisions

In a standard atmosphere, a chamber is filled with trillions of particles per cubic centimeter, primarily nitrogen, oxygen, and water vapor. When the coating material is vaporized, its atoms travel towards the target surface, or substrate.

Without a vacuum, these coating atoms would immediately collide with air particles, scattering them and preventing them from reaching the substrate in a uniform way.

Unwanted Chemical Reactions

Those collisions are not just physical obstructions. The highly energized coating atoms can react with gases like oxygen or water vapor.

This creates unwanted compounds, such as oxides, within the coating layer. The final film is no longer pure, leading to dramatically reduced performance, poor durability, and unpredictable properties.

Loss of Control and Uniformity

The goal of advanced coating is often to create an extremely thin, perfectly uniform film. In the presence of air, the random scattering and reactions make this level of control impossible.

The coating would be uneven, porous, and weakly bonded to the surface because a layer of air and contaminants would always remain on the substrate, preventing a direct atomic bond.

How a Vacuum Creates the Ideal Environment

By removing almost all the particles from the chamber, a vacuum transforms the environment from chaotic and reactive to clean and predictable. This allows for a fundamentally superior deposition process.

Establishing a Clear Path

Creating a vacuum drastically reduces the number of particles in the chamber. This increases the "mean free path"—the average distance a particle can travel before colliding with another one.

In a high vacuum, this path becomes longer than the chamber itself. This guarantees that coating atoms travel in a straight, uninterrupted line from the source to the substrate, ensuring uniform coverage.

Ensuring Absolute Purity

With reactive gases like oxygen removed, the coating material deposits in its pure form. The material that vaporizes from the source is the same material that arrives on the substrate.

This purity is critical for achieving the desired properties, whether it's the hardness of titanium nitride or the optical clarity of an anti-reflective coating.

Maximizing Adhesion and Density

Before the coating process begins, the vacuum helps remove residual contaminants and moisture from the substrate's surface.

When the pure stream of coating material arrives at this ultra-clean surface, it can form a much stronger, direct atomic bond. This results in a denser, less porous film that adheres far better and provides superior protection against wear and corrosion.

Understanding the Practical Trade-offs

While vacuum coating delivers exceptional results, it is a more complex and demanding process than applying a simple paint or dip. Understanding its limitations is key to using it effectively.

Process Complexity and Cost

Vacuum coating systems require sophisticated equipment, including sealed chambers, powerful pumps, and precise monitoring gauges. This represents a significant investment in both capital and operational expertise.

Slower Production Cycles

Achieving a high vacuum is not instantaneous. A significant portion of the process time is dedicated to "pumping down" the chamber to the required pressure level. This makes it a batch process, which can be slower than continuous, atmospheric coating methods.

Material Suitability

The process relies on either evaporating a material with heat or sputtering it with ions. Some complex materials or alloys may decompose or change their chemical structure under these conditions, making them unsuitable for standard vacuum deposition techniques.

Making the Right Choice for Your Goal

Deciding to use a vacuum coating process depends entirely on the performance you require from the final product.

- If your primary focus is maximum performance and durability: Vacuum coating is essential for creating the hard, wear-resistant, and corrosion-resistant surfaces demanded by aerospace, medical, and high-end tooling applications.

- If your primary focus is precision and optical clarity: For products like lenses, sensors, or microelectronics, the nanometer-level control and purity offered by vacuum deposition is non-negotiable.

- If your primary focus is the strongest possible bond: The ultra-clean environment of a vacuum is the only way to guarantee a dense, powerful, and uncontaminated bond between the coating and the substrate.

Ultimately, using a vacuum is about achieving total control over the coating environment, which is the foundation for creating high-performance, precision-engineered surfaces.

Summary Table:

| Problem Without Vacuum | Benefit With Vacuum |

|---|---|

| Contamination from air particle collisions | Pure, uninterrupted material deposition |

| Unwanted chemical reactions (e.g., oxidation) | Clean, predictable coating properties |

| Poor adhesion and uneven coverage | Strong atomic bond and uniform film |

| Uncontrolled, porous layers | Dense, high-performance coatings |

Need a high-performance coating solution for your lab? KINTEK specializes in vacuum coating equipment and consumables, delivering the precision and purity required for aerospace, medical, and optical applications. Contact us today to discuss how our solutions can enhance your coating process and product performance!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications