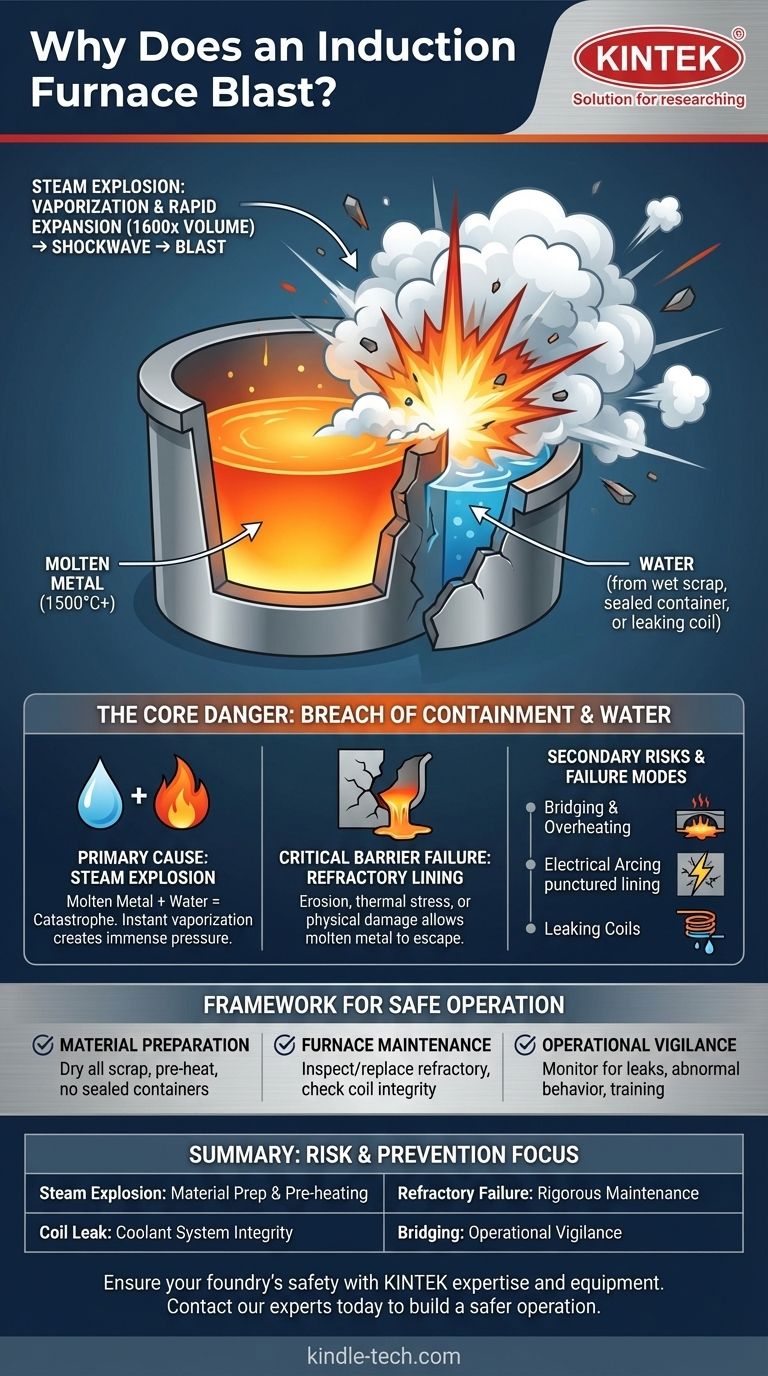

At its core, an induction furnace "blasts" or explodes due to a catastrophic and near-instantaneous pressure event. The most common and violent cause is not an electrical failure, but a steam explosion, which occurs when superheated molten metal makes contact with water. This contact instantly vaporizes the water, causing it to expand to over 1,600 times its original volume, creating a shockwave that destroys the furnace structure.

The fundamental danger in an induction furnace is not the induction process itself, but a breach of containment. When the protective refractory lining fails, it allows molten metal to interact with external elements—most dangerously, water—leading to a violent physical reaction, not a chemical or electrical one.

How an Induction Furnace Sets the Stage

To understand the failure, we must first understand the normal operation. An induction furnace is an incredibly powerful tool that uses fundamental physics to melt metal without direct flame.

The Principle of Induction

A large, water-cooled copper coil surrounds a non-conductive container, called a crucible. When a powerful alternating current is passed through this coil, it generates a strong, rapidly changing magnetic field. This magnetic field induces powerful electrical currents (eddy currents) within the metal scrap inside the crucible. The metal's natural resistance to these currents generates immense heat, causing it to melt.

The Crucible: The Critical Barrier

The crucible, which holds the molten metal, is made of a refractory material. This material is designed to be a poor electrical conductor while being able to withstand extreme temperatures. It is the single most important safety barrier, keeping the superheated, liquid metal separated from the outside world, especially the water-cooled induction coils.

The Primary Cause of Explosions: Water

The vast majority of violent furnace incidents are steam explosions. The energy released is immense and occurs faster than any system can handle.

Molten Metal + Water = Catastrophe

Water boils at 100°C (212°F). Molten steel or iron is often above 1,500°C (2,750°F). When this incredibly hot liquid envelops a small amount of water, it transfers its thermal energy almost instantly. The water doesn't boil; it flashes into steam in a fraction of a second.

The Physics of a Steam Explosion

This rapid phase change from liquid to gas creates a massive increase in volume. A single liter of water can expand into over 1,600 liters of steam. When this happens in a confined or semi-confined space, it generates a pressure wave identical to a conventional explosion, ejecting molten metal and destroying equipment.

Common Sources of Water Contamination

Preventing an explosion is about controlling water. The most common sources include:

- Wet Scrap: Scrap metal stored outdoors can contain rain, snow, or ice.

- Sealed Containers: Sealed pipes or hollow vessels in the scrap can contain trapped moisture, turning them into literal bombs when heated.

- Leaking Coils: The induction coils themselves are cooled by circulating water. A small leak from a coil can introduce water directly into a compromised crucible, creating the most dangerous scenario possible.

Understanding the Secondary Risks and Failure Modes

While steam is the primary culprit, other factors can lead to furnace failure, often by creating the conditions for a steam explosion.

Refractory Lining Failure

The crucible's refractory lining is the furnace's weak point. It erodes over time due to thermal stress, chemical reactions with the melt, and physical abrasion. If it is not monitored and replaced, a crack or full breach can occur. This allows molten metal to escape the crucible and contact the water-cooled copper coils, triggering a guaranteed steam explosion.

Bridging and Overheating

If scrap metal forms a "bridge" over the molten bath below, the lower portion can overheat significantly while the top remains solid. When the bridge finally collapses, it can cause a violent splash of superheated metal, which can damage the refractory and potentially find a path to water.

Electrical Arcing

A severe electrical fault, such as an arc from the coil to the metal charge, can puncture the refractory lining. This provides a direct path for molten metal to escape, leading to the same catastrophic outcome if it finds water.

A Framework for Safe Operation

Understanding these failure modes is the key to prevention. The focus must always be on maintaining containment and eliminating water.

- If your primary focus is material preparation: Your absolute priority is ensuring all scrap is dry. Implement mandatory pre-heating protocols to drive off any moisture before charging the furnace.

- If your primary focus is furnace maintenance: Your goal is to guarantee crucible integrity. Adhere to a strict schedule for inspecting, patching, and replacing the refractory lining and for checking the coolant coils for any signs of leaks.

- If your primary focus is day-to-day operations: Your responsibility is vigilance. Never charge sealed containers, and always be trained to recognize the signs of a water leak or abnormal furnace behavior.

By treating the induction furnace as a system where containment is paramount, you can mitigate the risks and operate it with confidence.

Summary Table:

| Primary Cause of Blast | Key Risk Factors | Critical Prevention Focus |

|---|---|---|

| Steam Explosion | Wet Scrap, Sealed Containers | Material Preparation & Pre-heating |

| Refractory Lining Failure | Lining Erosion, Cracks | Rigorous Maintenance & Inspection Schedule |

| Water-Cooled Coil Leak | Coil Damage, Corrosion | Coolant System Integrity Checks |

| Bridging & Overheating | Poor Scrap Charging Practices | Operational Vigilance & Training |

Ensure your foundry's safety and operational integrity. The catastrophic failure of an induction furnace is preventable with the right expertise and equipment. KINTEK specializes in lab and foundry equipment, offering crucibles, refractory materials, and safety solutions designed for extreme temperatures and demanding environments. Our products help you maintain the critical barrier between molten metal and hazards, protecting your personnel and investment. Don't compromise on safety—contact our experts today to discuss your specific furnace requirements and build a safer, more reliable operation.

Visual Guide

Related Products

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- What are the different melting methods? A Guide to Choosing the Right Industrial Furnace

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab