Fundamentally, a vacuum environment is essential for Physical Vapor Deposition (PVD) because it creates the pristine, controlled conditions necessary for the process to work. Without a vacuum, the vaporized coating material would collide with billions of air particles, never reaching the target substrate, and any film that did form would be hopelessly contaminated by atmospheric gases, rendering it useless.

The core purpose of the vacuum in PVD is twofold: it ensures that coating particles have a clear, unobstructed path from the source to the substrate, and it eliminates atmospheric gases that would otherwise contaminate and ruin the chemical and structural integrity of the final coating.

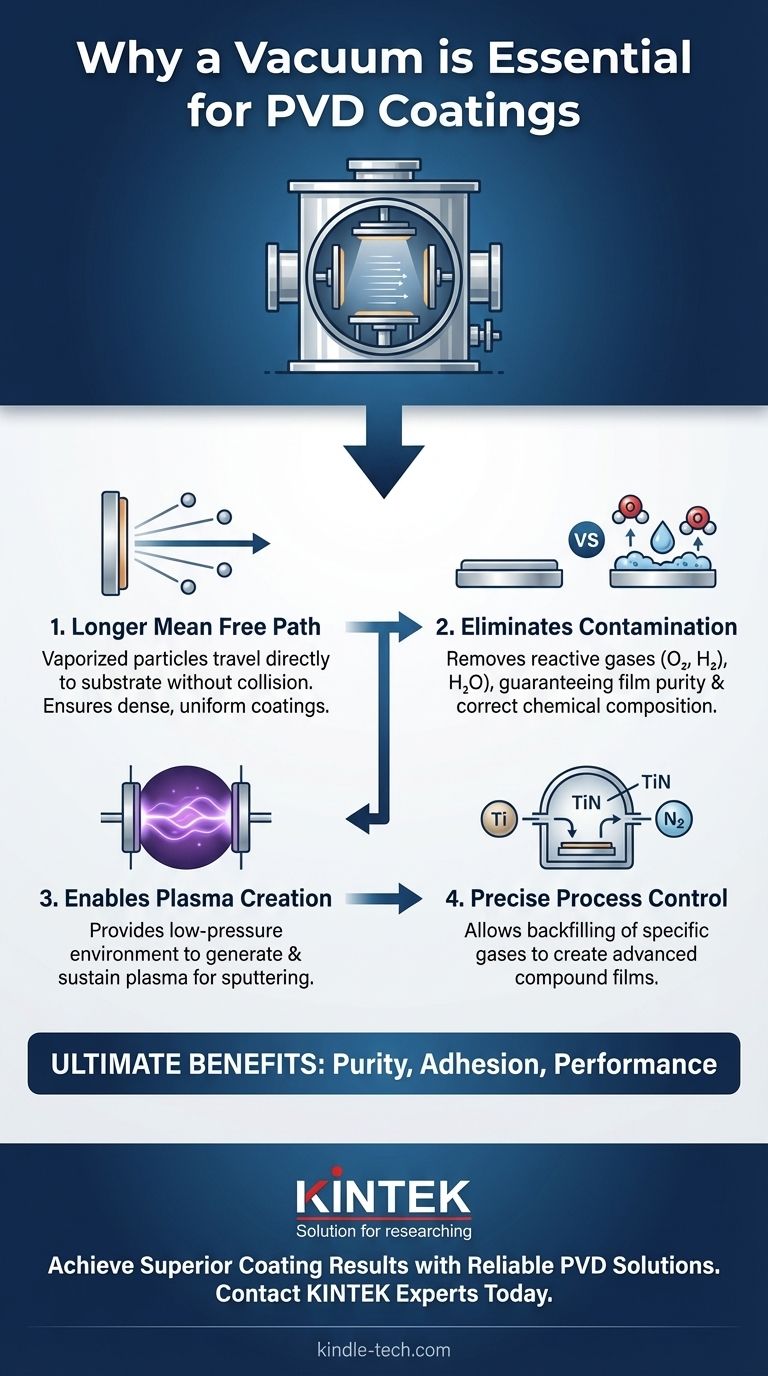

Why a Vacuum is Non-Negotiable for Quality Coatings

To understand PVD is to understand the physics of a vacuum. The process involves creating a vapor of a material and having it condense on a part to form a high-performance coating. This entire journey, from vapor creation to condensation, must be meticulously controlled.

The "Mean Free Path": Ensuring a Direct Flight

In a PVD chamber, we are moving individual atoms or molecules from a source (the "target") to the substrate (the part being coated). The mean free path is the average distance a particle can travel before colliding with another particle.

At atmospheric pressure, the air is dense with nitrogen, oxygen, and other gas molecules. The mean free path is incredibly short—on the scale of nanometers. Vaporized coating atoms would collide almost instantly, scattering in random directions and losing energy.

By pumping the chamber down to a high vacuum, we remove the vast majority of these air molecules. This dramatically increases the mean free path, allowing the coating atoms to travel in a straight line-of-sight path from the source to the substrate, much like a ball thrown in an empty room versus one thrown in a room full of obstacles.

Purity is Paramount: Removing Unwanted Contaminants

The atmosphere is highly reactive. Gases like oxygen and water vapor are aggressive contaminants that will readily react with the hot, energetic coating atoms and the clean substrate surface.

This contamination leads to poor film adhesion, incorrect chemical composition, and undesirable properties like reduced hardness or increased friction. For example, if you are depositing a pure titanium film, any oxygen present will create titanium oxide, changing the coating entirely.

A vacuum environment effectively removes these reactive contaminants, ensuring the deposited film is as pure as the source material.

Enabling the Plasma Environment

Many PVD processes, such as sputtering, use a low-pressure plasma (an ionized gas, typically Argon) to bombard the source material and eject atoms.

A vacuum is a prerequisite for creating and sustaining this controlled plasma. It's impossible to generate a stable, low-pressure plasma at atmospheric pressure. The vacuum allows for precise control over the pressure and composition of the specific gases (like Argon) needed to drive the process.

Total Control Over the Process Atmosphere

Sometimes, we intentionally introduce a specific gas into the vacuum chamber to create a desired compound. This is called reactive PVD.

For example, to create a hard, gold-colored Titanium Nitride (TiN) coating, we vaporize titanium in a vacuum environment where we have precisely backfilled a small, controlled amount of nitrogen gas. The vacuum allows us to control the exact ratio of reactive gas to vaporized metal, giving us precise control over the final coating's stoichiometry and properties.

The Practical Costs of a Perfect Environment

While essential, creating and maintaining a vacuum is the primary source of complexity and cost in PVD. It is not a trivial undertaking.

Equipment and Maintenance Costs

High-vacuum pumps (like turbo-molecular and cryogenic pumps), chamber hardware, and the associated gauges and controllers are expensive. They require regular, specialized maintenance to ensure they operate correctly and do not develop leaks.

Increased Process Time

Before the coating process can even begin, the chamber must be pumped down to the target vacuum level. This "pump-down" time can range from minutes to hours, depending on the chamber size and pump performance, which directly impacts throughput and operational efficiency.

Process Complexity

Operating a vacuum system requires a skilled technician. Monitoring for leaks, managing pump cycles, and troubleshooting pressure issues are critical tasks that demand expertise. An undetected leak can compromise an entire batch of coated parts.

Linking Vacuum Principles to Your Coating Goals

Understanding why a vacuum is necessary allows you to appreciate what makes a PVD coating successful. The level of vacuum directly correlates with the final quality of the product.

- If your primary focus is film purity and chemical accuracy: The vacuum's role in eliminating reactive atmospheric contaminants is the most critical factor for your success.

- If your primary focus is a dense, adherent, and uniform coating: The vacuum's ability to ensure a long mean free path is paramount, as it allows high-energy atoms to reach the substrate without scattering.

- If your primary focus is creating advanced compound films (e.g., nitrides, oxides): The vacuum's function as a blank slate, allowing precise backfilling of specific reactive gases, is the key enabler of your process.

Ultimately, the vacuum is not just a peripheral requirement; it is the foundational element that makes modern, high-performance thin-film deposition possible.

Summary Table:

| Key Reason | Impact on PVD Coating |

|---|---|

| Longer Mean Free Path | Allows vaporized particles to travel directly to the substrate, ensuring dense, uniform coatings. |

| Eliminates Contamination | Removes reactive gases like oxygen and water vapor, guaranteeing film purity and correct chemical composition. |

| Enables Plasma Creation | Provides the controlled low-pressure environment needed to generate and sustain the plasma used in sputtering. |

| Precise Process Control | Acts as a blank slate for introducing specific reactive gases to create advanced compound films like TiN. |

Ready to achieve superior coating results with a reliable PVD system? KINTEK specializes in high-performance lab equipment, including vacuum solutions for Physical Vapor Deposition. Our expertise ensures your process delivers the purity, adhesion, and performance your applications demand. Contact our experts today to discuss how we can support your laboratory's coating needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications