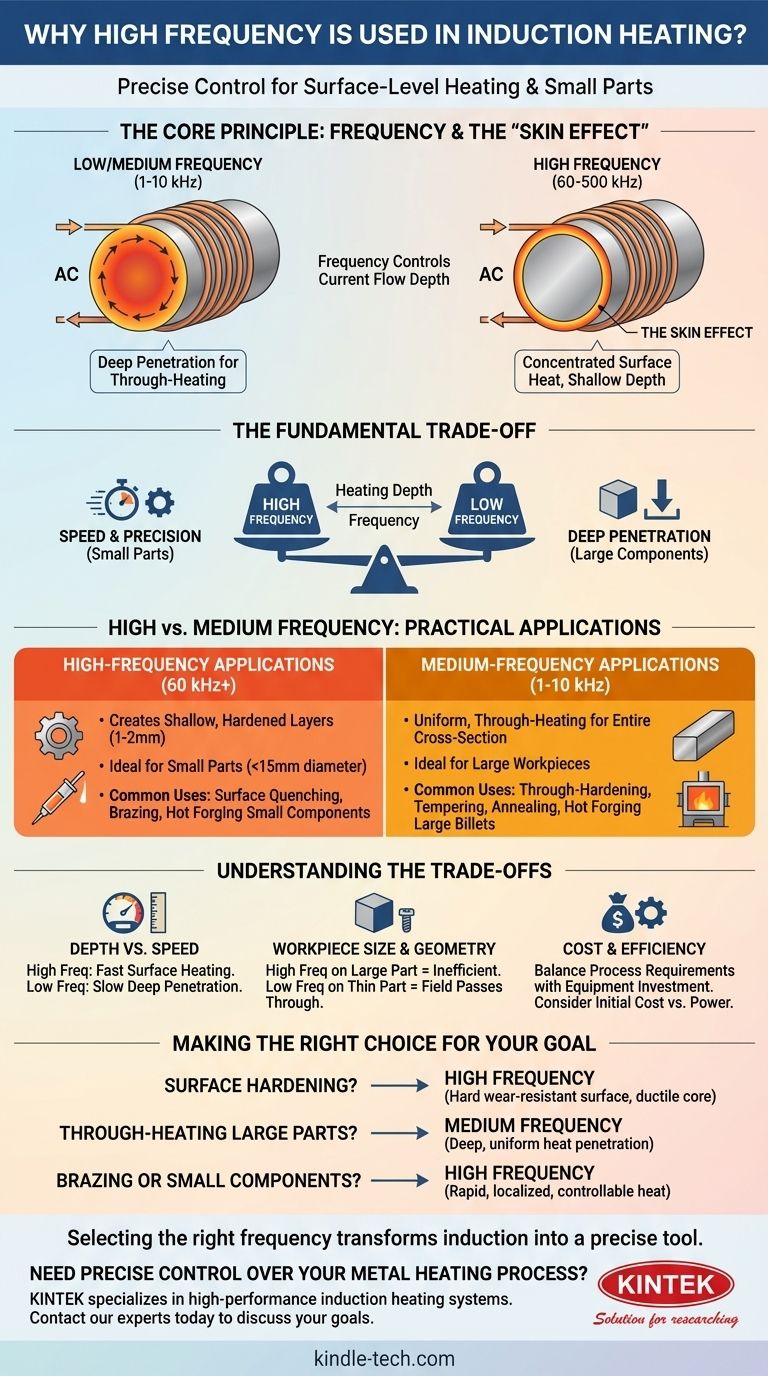

In induction heating, high frequency is used to precisely control and concentrate heat near the surface of a workpiece. This effect is essential for processes like surface hardening, brazing, or heating small, thin parts where deep heat penetration is unnecessary or undesirable. The higher the frequency, the shallower the heat penetration, allowing for rapid and efficient surface-level heating.

The fundamental trade-off in induction heating is between heating depth and frequency. High frequency confines energy to the surface for fast, precise work on smaller parts, while low frequency drives heat deep into larger components for through-hardening or forging.

The Core Principle: Frequency and the "Skin Effect"

What is the Skin Effect?

Induction heating works by inducing an electrical current within a metal part. The "skin effect" is a natural phenomenon where this alternating current (AC) tends to flow in a thin layer, or "skin," near the object's surface.

The resistance of the metal to this current flow is what generates the heat. By controlling where the current flows, you can control precisely where the heating occurs.

How Frequency Controls Heating Depth

The frequency of the alternating current is the primary tool for controlling the thickness of this skin.

A high-frequency current (typically 60 kHz to 500 kHz) reverses direction very rapidly, forcing the electrical current into a much thinner layer. This concentrates an immense amount of heating energy directly at the surface.

A low or medium-frequency current (1 kHz to 10 kHz) allows the current to penetrate much deeper into the part, resulting in more uniform, through-heating. The depth of this heated layer is often called the electrical reference depth.

High vs. Medium Frequency: A Practical Comparison

The choice of frequency is dictated entirely by the material, the size of the part, and the desired outcome of the heating process.

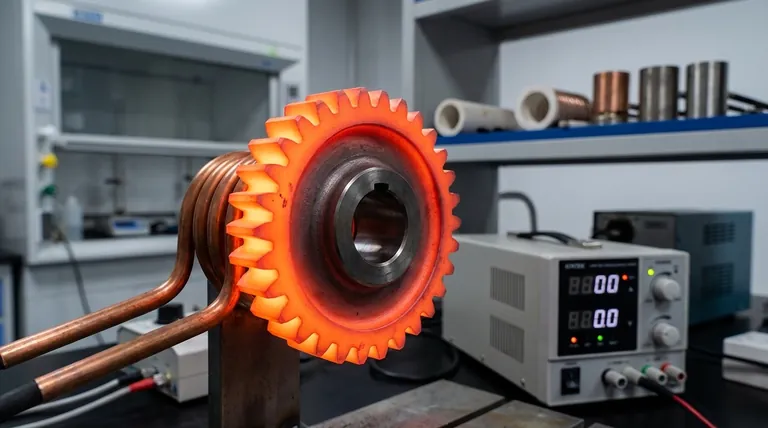

High-Frequency Applications (60 kHz+)

High-frequency systems excel at heating small parts or creating shallow, hardened layers. The heat is generated quickly and precisely on the surface, often creating a hardened case of just 1-2mm deep.

Common uses include surface quenching, brazing, hot forging small components, and any process involving parts smaller than approximately 15mm in diameter.

Medium-Frequency Applications (1 kHz - 10 kHz)

Medium-frequency systems are the solution for heating large workpieces that require deep heat penetration. They are ideal for applications where the entire cross-section of a part needs to be heated uniformly.

Typical uses include the through-hardening, tempering, annealing, and hot forging of large metal billets or components.

Understanding the Trade-offs

Choosing the wrong frequency leads to inefficiency, poor results, and wasted energy. The decision involves balancing several key factors.

Depth vs. Speed

High frequency heats the surface layer extremely fast but is inefficient for heating the core of a large part. Conversely, low frequency penetrates deeply but takes longer to bring the entire mass up to temperature.

Workpiece Size and Geometry

The size of the part is critical. Using a high frequency on a very large workpiece is like trying to cook a turkey with a small torch—only the skin will heat up. Using a low frequency on a very thin part is inefficient, as the heating field may pass right through it.

Cost and Efficiency

The choice also has financial implications. For some workpieces, a lower-power high-frequency machine might achieve the same result as a higher-power medium-frequency machine, but at a lower initial cost. The decision must balance process requirements with equipment investment.

Making the Right Choice for Your Goal

Ultimately, the optimal frequency is determined by the specific metallurgical goal for your workpiece.

- If your primary focus is surface hardening or case hardening: High frequency is the correct choice to create a hard, wear-resistant surface while leaving the core ductile.

- If your primary focus is through-heating a large part for forging or tempering: Medium frequency is required to ensure deep and uniform heat penetration.

- If your primary focus is brazing or heating very small components: High frequency provides the rapid, localized, and controllable heat needed for these precise applications.

Selecting the right frequency transforms induction from a simple heating method into a precise tool for engineering specific material properties.

Summary Table:

| Frequency Range | Primary Use Case | Heating Depth | Ideal For |

|---|---|---|---|

| High (60 kHz+) | Surface Heating | Shallow (1-2mm) | Surface hardening, brazing, small/thin parts |

| Medium (1-10 kHz) | Deep Penetration | Deep & Uniform | Through-hardening, annealing, large billets |

Need precise control over your metal heating process?

KINTEK specializes in high-performance induction heating systems for laboratories and industrial applications. Whether you require high-frequency precision for surface hardening or medium-frequency power for deep penetration, our equipment ensures efficiency, repeatability, and superior results.

Contact our experts today to discuss your specific material, part size, and metallurgical goals. We'll help you select the ideal frequency and system to enhance your lab's capabilities and productivity.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Double Plate Heating Press Mold for Lab

- Vacuum Cold Trap Direct Cold Trap Chiller

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is SiC elements? The Ultimate High-Temperature Heating Solution

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes