In short, hydrogen is used in sintering furnaces to create a powerful reducing atmosphere. This atmosphere is critical because it actively prevents the metal powders from oxidizing at high temperatures and chemically strips away existing surface oxides and other impurities, resulting in parts with superior purity, mechanical strength, and a bright finish.

A sintering furnace's atmosphere is not just a passive shield; it is an active chemical agent. Using hydrogen transforms the furnace environment from a potential source of contamination (oxygen) into an active purification system, which is essential for high-performance materials.

The Role of a Reducing Atmosphere in Sintering

Sintering involves bonding material powders together using heat, just below their melting point. At these high temperatures, most metals are extremely reactive with oxygen. Using hydrogen directly addresses this fundamental challenge.

What is a Reducing Atmosphere?

A reducing atmosphere is an environment that is intentionally starved of oxygen and rich in a reducing agent, in this case, hydrogen (H₂).

This type of atmosphere actively works to remove oxygen by reacting with it to form water vapor (H₂O), which is then flushed from the furnace.

Preventing Oxidation During the Process

The primary job of the hydrogen atmosphere is preventing oxidation. Without it, oxygen in the air would rapidly form oxide layers on the surfaces of the metal powder particles.

These oxide layers act as a barrier, inhibiting the particles from properly bonding together. This leads to parts with poor density, reduced strength, and compromised mechanical properties.

Actively Cleaning the Material

Beyond just preventing new oxides, hydrogen's high reactivity at sintering temperatures allows it to strip away pre-existing oxides and other impurities from the powder surfaces.

For instance, it can effectively reduce silica impurities, pulling oxygen atoms away from the material and ensuring a cleaner, more chemically pure bond between particles.

The Result: Superior Part Quality

This active chemical purification directly translates to a higher quality final product.

Parts sintered in hydrogen typically exhibit a bright, clean surface finish, a higher aggregation ratio (better bonding), and significantly improved mechanical qualities like strength and ductility.

What Materials Require Hydrogen Sintering?

The need for a hydrogen atmosphere is dictated by the material's sensitivity to oxygen and the desired final properties.

High-Performance and Refractory Metals

Materials like tungsten and molybdenum have very high melting points and are highly susceptible to oxidation at sintering temperatures. Hydrogen sintering is standard practice for producing dense, pure parts from these metals.

Stainless Steels and Specialty Alloys

Many stainless steels, tungsten carbide, and other high-performance alloys are sintered in hydrogen to achieve the highest possible density and strength while maintaining a clean, bright surface without post-processing.

Advanced Cermets

Certain ceramic-metallic compositions (cermets) rely on hydrogen sintering to create specialized parts. The reducing atmosphere ensures a strong bond between the dissimilar materials, which is critical for achieving unique physical properties.

Understanding the Trade-offs and Risks

While highly effective, using hydrogen is a significant operational decision with clear trade-offs. It is not a universally superior solution for all sintering applications.

The Critical Risk of Explosion

Hydrogen is highly flammable and can form an explosive mixture with air. This is the single most significant risk and requires robust safety protocols, specialized furnace designs with purge cycles, and continuous atmosphere monitoring to prevent catastrophic failure.

Component Degradation and Furnace Design

Even within the reducing atmosphere, certain furnace components like electrical heating elements can become brittle over time.

Furthermore, the furnace itself must be constructed with specific refractory materials, such as high-purity alumina, that will not react with the hydrogen at extreme temperatures. This increases the cost and complexity of the equipment.

Sourcing and Logistics

Unlike nitrogen or argon, obtaining and storing the required volume of high-purity hydrogen can be a logistical challenge, adding to the operational complexity and cost of the process.

Making the Right Choice for Your Process

Choosing the right furnace atmosphere depends entirely on your material, safety requirements, and production goals. For many applications, a vacuum furnace provides an alternative path to achieving clean parts.

- If your primary focus is maximum purity for oxygen-sensitive materials: Hydrogen sintering is the ideal choice for its active chemical cleaning and oxide-reducing capabilities.

- If your primary focus is safety, versatility, and lower complexity: A vacuum furnace, which removes air mechanically, is an excellent alternative that produces clean, bright parts without the risks associated with a flammable gas.

- If your primary focus is sintering tungsten, molybdenum, or specific carbides: A hydrogen atmosphere is often the industry-standard requirement to achieve the necessary part density and purity.

Ultimately, selecting the right atmosphere is a critical engineering decision that directly impacts part quality, operational safety, and overall cost.

Summary Table:

| Key Function | Benefit |

|---|---|

| Prevents Oxidation | Ensures strong particle bonding for high density and strength |

| Removes Impurities | Chemically strips oxides for superior purity and bright finish |

| Ideal for Refractory Metals | Essential for sintering tungsten, molybdenum, and carbides |

| Critical Safety Consideration | Requires specialized furnace design and safety protocols |

Achieve maximum purity and strength in your sintered parts with KINTEK.

Our expertise in lab equipment and consumables means we understand the critical role of furnace atmosphere in your process. Whether you are sintering high-performance metals, stainless steels, or advanced alloys, the right equipment is key to success and safety.

Let our specialists help you select the perfect sintering solution for your laboratory's specific needs. Contact KINTEK today to discuss how we can enhance your sintering process and results.

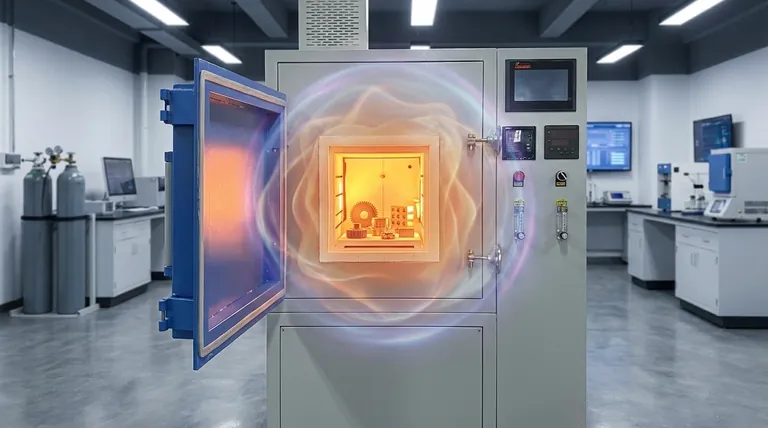

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are hydrogen furnaces used for? Achieve Purity and Speed in High-Temperature Processing

- Why must a hydrogen-reducing atmosphere be maintained for tungsten annealing? Ensure Purity in High-Temp Processing

- What is hydrogen atmosphere heat treatment? Achieve Superior Surface Purity & Brightness

- What is hydrogen annealing? Achieve Superior Material Properties with Bright Annealing

- When would you need to use a controlled atmosphere? Prevent Contamination and Control Reactions