In short, Chemical Vapor Deposition (CVD) is performed at low pressures to achieve superior film quality. Lowering the pressure fundamentally changes how precursor gas molecules travel and react, resulting in films with significantly better uniformity and the ability to coat complex, three-dimensional surfaces evenly.

The central concept to grasp is that pressure is not just a background condition; it is the primary control knob for the gas transport mechanism. Shifting from atmospheric to low pressure changes the process from being limited by gas diffusion to being limited by the surface reaction rate, which is the key to producing high-performance, conformal thin films.

The Fundamental Role of Pressure in CVD

To understand the benefits of low pressure, we must first examine how pressure affects the behavior of gas molecules inside a deposition chamber. The entire process hinges on controlling the path these molecules take from the gas inlet to the substrate surface.

Gas Density and Mean Free Path

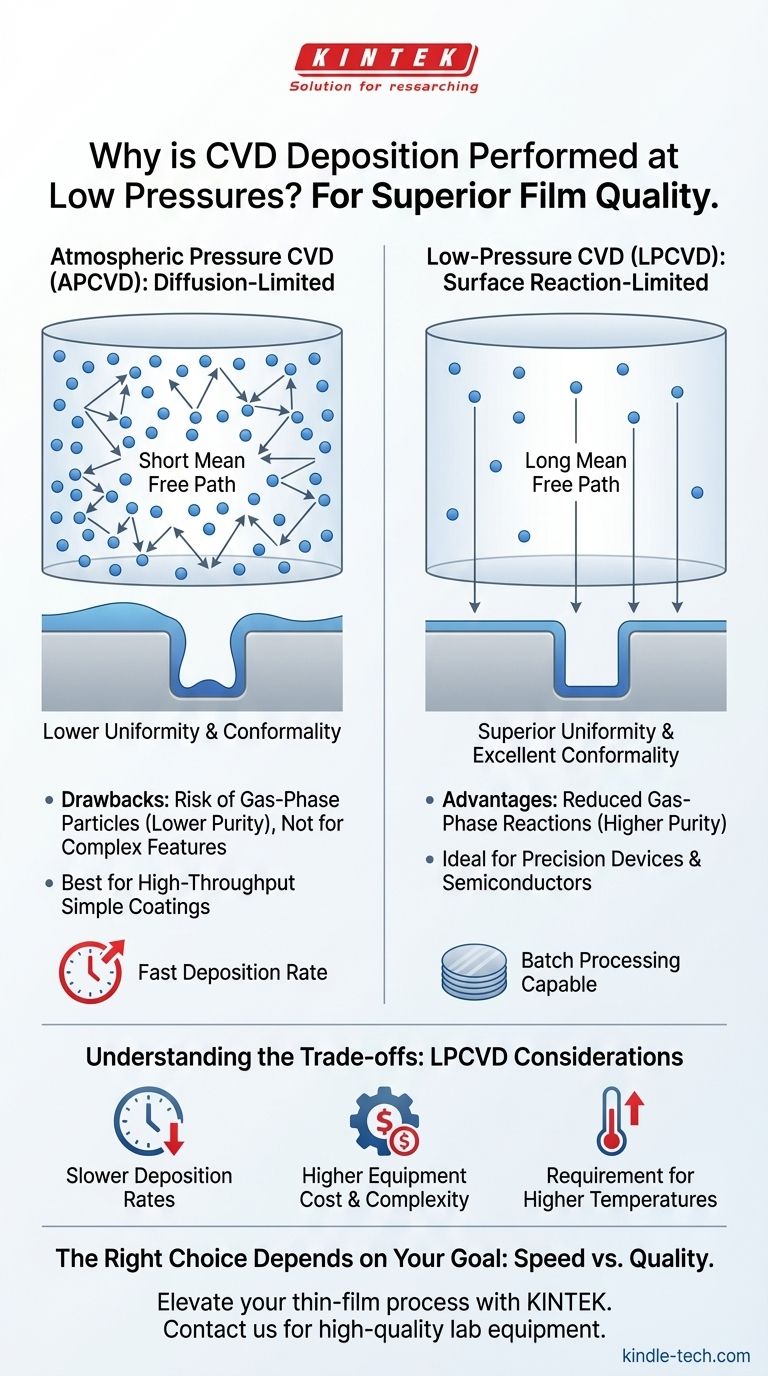

At atmospheric pressure, the CVD chamber is crowded with gas molecules. This high density means that precursor molecules are constantly colliding with each other. The average distance a molecule can travel before a collision, known as the mean free path, is very short.

By pumping the chamber down to a low pressure (LPCVD), we dramatically reduce the number of gas molecules. This significantly increases the mean free path, allowing molecules to travel much farther in straight lines before being deflected.

Shifting from Diffusion to Surface Reaction Control

This change in mean free path creates two distinct deposition regimes.

At atmospheric pressure (APCVD), the process is diffusion-limited. Precursor molecules undergo a random walk of countless collisions to reach the substrate. This can lead to depletion of the gas near the surface, causing the film to grow thicker at the edges of the wafer and thinner in the center.

At low pressure (LPCVD), the process becomes surface reaction rate-limited. With a long mean free path, molecules can travel directly to the substrate from all directions. The film growth is no longer limited by gas transport but by the speed of the chemical reaction on the hot surface itself, which is far more uniform across the entire substrate.

Key Advantages of Low-Pressure CVD (LPCVD)

The shift to a surface-reaction-limited regime provides several critical advantages, particularly for demanding applications like semiconductor manufacturing.

Superior Film Uniformity

Because the deposition rate is governed by the surface temperature and chemistry—which are uniform across the substrate—the resulting film thickness is extremely consistent. This uniformity allows for batch processing where many wafers can be stacked vertically in a furnace, as the gas can easily penetrate and coat them all evenly.

Excellent Conformality

Conformality is the ability of a film to evenly coat complex topography, such as deep trenches or steps on a microchip. The long mean free path in LPCVD means precursor molecules arrive at the surface from a wide range of angles, ensuring that sidewalls and bottoms of features are coated just as thickly as the top surfaces.

Reduced Gas-Phase Reactions

The frequent collisions in APCVD can cause chemical reactions to occur in the gas phase before the precursors even reach the substrate. This can form particles that fall onto the surface, creating defects and impurities in the film. The reduced molecular density in LPCVD suppresses these unwanted gas-phase reactions, leading to higher purity films.

Understanding the Trade-offs: Why Not Always Use Low Pressure?

While LPCVD offers superior quality, it is not the ideal choice for every application. Atmospheric pressure CVD retains its place due to a different set of priorities.

Slower Deposition Rates

The primary drawback of LPCVD is a significantly lower deposition rate. With fewer precursor molecules in the chamber, fewer are available to react on the surface per unit of time. For applications where film quality is less critical than high throughput, this can be a major disadvantage.

Higher Equipment Cost and Complexity

Operating at low pressure requires a vacuum system, including robust vacuum pumps and more complex reactor designs to maintain a seal. This makes LPCVD systems more expensive to purchase and operate than their simpler atmospheric pressure counterparts.

Requirement for Higher Temperatures

To achieve a reasonable chemical reaction rate on the surface with a lower concentration of precursors, LPCVD processes often require higher substrate temperatures than APCVD. This can be a limitation for substrates or underlying device structures that are sensitive to heat.

Choosing the Right Pressure for Your Application

The decision between atmospheric and low-pressure CVD is a classic engineering trade-off between speed and quality. Your ultimate goal determines the correct approach.

- If your primary focus is high-volume throughput for simple coatings: APCVD is often the better choice due to its high deposition rates and lower equipment cost.

- If your primary focus is precision and film quality for complex devices: LPCVD is the necessary choice for its superior uniformity, conformality, and purity.

Ultimately, controlling the pressure in a CVD system is the most powerful method for controlling the quality and fundamental character of the final material.

Summary Table:

| Feature | Atmospheric Pressure CVD (APCVD) | Low-Pressure CVD (LPCVD) |

|---|---|---|

| Process Control | Diffusion-Limited | Surface Reaction-Limited |

| Film Uniformity | Lower (thicker at edges) | Superior (highly uniform) |

| Conformality | Poor for complex features | Excellent (coats trenches evenly) |

| Deposition Rate | High | Slower |

| Film Purity | Lower (risk of gas-phase particles) | Higher (reduced gas-phase reactions) |

| Typical Application | High-throughput, simple coatings | Precision devices, semiconductors |

Ready to elevate your thin-film deposition process? The choice between APCVD and LPCVD is critical for achieving your specific performance goals. KINTEK specializes in providing high-quality lab equipment and consumables for all your laboratory needs. Our experts can help you select the ideal CVD solution for superior film quality, uniformity, and conformality. Contact us today to discuss how we can support your research and production with the right technology!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the key functions of the high-temperature vacuum or atmosphere reaction retort? Maximize CVD Coating Success

- What is the thin film deposition method? A Guide to PVD & CVD Techniques

- What is the pressure to create synthetic diamonds? HPHT vs. CVD Methods Explained

- How do you deposit thin film? PVD vs. CVD Methods for Precision Coating

- What is CVD in MEMS? The Foundational Process for Building Micro-Scale Devices

- What is chemical vapor deposition for CNT? The Leading Method for Scalable Carbon Nanotube Synthesis

- What is the process of deposition in a wafer? A Guide to CVD and PVD Methods

- What is the chemical deposition technique? A Guide to Building High-Performance Thin Films