In short, high frequency is used for induction heating because it allows for precise control over where the heat is generated. A higher frequency concentrates the heating effect on the surface of a metal part, making it ideal for applications like surface hardening, brazing, or heating small components quickly and efficiently.

The core principle to understand is that frequency acts as the primary control for heating depth. Higher frequencies create shallow, precise heat near the surface, while lower frequencies penetrate deeper into the workpiece.

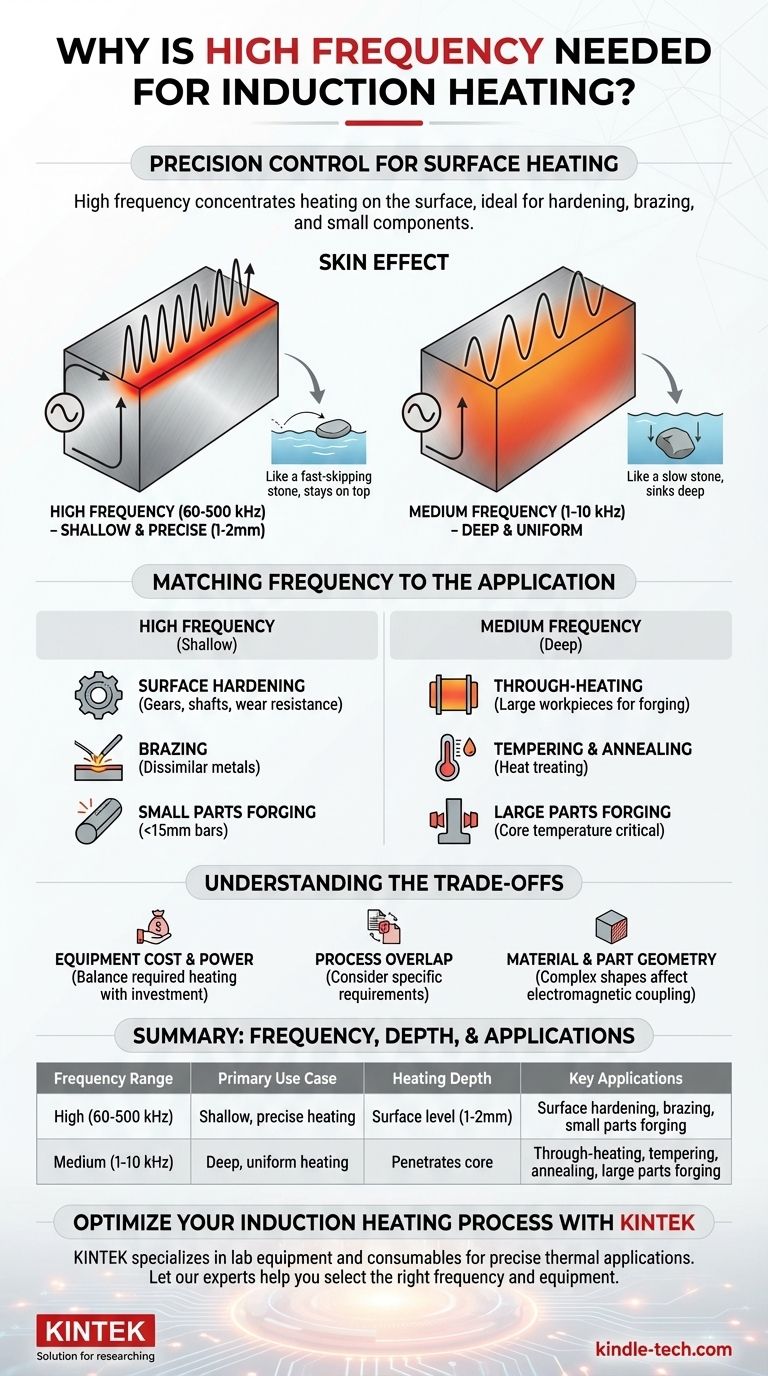

The Fundamental Principle: The "Skin Effect"

The relationship between frequency and heating depth is governed by a physical principle known as the "skin effect." Understanding this concept is key to mastering induction heating.

What is the Skin Effect?

When an alternating current (AC) flows through a conductor, it tends to distribute itself unevenly. More of the current flows near the outer surface, or "skin," of the conductor.

This effect becomes more pronounced as the frequency of the current increases.

How Frequency Controls Heating Depth

A high-frequency current stays tightly confined to the surface, generating intense heat in a very thin layer. Think of it like a fast-skipping stone that only interacts with the very top of the water.

A low or medium-frequency current penetrates much deeper into the material before generating heat. This is like a slow-moving stone that sinks deep below the surface.

The Result: Precise, Surface-Level Heat

By using high frequencies, engineers can heat just the surface of a gear tooth to harden it, leaving the core tough and ductile. This precision is impossible to achieve with lower frequencies, which would heat the entire gear.

Matching Frequency to the Application

The choice between high and medium frequency is dictated entirely by the size of the part and the desired outcome of the heating process.

High Frequency (Typically 60 kHz - 500 kHz)

High-frequency induction is the tool of choice for shallow and precise heating tasks.

Its primary applications include surface hardening (quenching) where only a thin layer of 1-2mm needs to be heated, brazing dissimilar metals, and the rapid hot forging of very small parts, like bars under 15mm in diameter.

Medium Frequency (Typically 1 kHz - 10 kHz)

Medium-frequency induction is used when heat needs to penetrate deep into a part or heat a large mass uniformly.

This makes it ideal for through-heating large workpieces for forging, tempering, annealing, and any process where the core temperature of the part is just as important as the surface temperature.

Understanding the Trade-offs

Selecting the right frequency is not just a technical decision; it also involves practical and economic considerations.

Equipment Cost and Power

Generally, the equipment required to generate different frequencies comes with different costs and power capabilities. The decision must balance the required heating effect with the capital investment.

Process Overlap

For some workpieces, the lines can blur. A higher-power medium-frequency machine might achieve a similar heating effect as a lower-power high-frequency machine, so the specific process requirements must be carefully considered.

Material and Part Geometry

The material of the workpiece and its specific shape also influence how the electromagnetic field couples with it. What works for a simple steel rod may need to be adjusted for a complex gear with fine teeth.

Making the Right Choice for Your Goal

The optimal frequency is the one that best serves the engineering goal for a specific part and process.

- If your primary focus is surface hardening, brazing, or heating small parts: High-frequency induction provides the necessary precision and speed.

- If your primary focus is through-heating, tempering, or forging large parts: Medium-frequency induction ensures the heat penetrates deeply and uniformly.

- If your primary focus is achieving a specific hardness depth on a complex part: You must balance frequency, power, and heating time to hit the precise target.

Ultimately, selecting the correct frequency is the most critical factor in achieving efficient, repeatable, and successful induction heating results.

Summary Table:

| Frequency Range | Primary Use Case | Heating Depth | Key Applications |

|---|---|---|---|

| High (60-500 kHz) | Shallow, precise heating | Surface level (1-2mm) | Surface hardening, brazing, small parts forging |

| Medium (1-10 kHz) | Deep, uniform heating | Penetrates core | Through-heating, tempering, annealing, large parts forging |

Ready to optimize your induction heating process? KINTEK specializes in lab equipment and consumables, providing tailored solutions for precise thermal applications like surface hardening and brazing. Let our experts help you select the right frequency and equipment for your specific needs. Contact us today to enhance your lab's efficiency and achieve repeatable, high-quality results!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- Why is heating rate control essential for LOCA simulation tests? Ensure Precision in Nuclear Safety Research

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- How does a vacuum hot press furnace address structural defects in as-cast CoCrPtB alloy ingots? Optimize Your Density

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- Why is it necessary to maintain a high-vacuum environment within a vacuum hot press furnace? Optimize Cu-SiC Sintering