In almost all cases, a hydraulic press fails to hold pressure because hydraulic fluid is escaping its intended path. This loss can be traced to either an obvious external leak from a failed seal or fitting, or a more subtle internal leak within a component like a valve or the main cylinder.

A hydraulic press is a closed-loop system; pressure is simply force applied over an area. If that pressure cannot be maintained, it means the fluid that transmits the force is leaking, either externally where you can see it, or internally where you cannot. Your task is to systematically trace the fluid's path to find that leak.

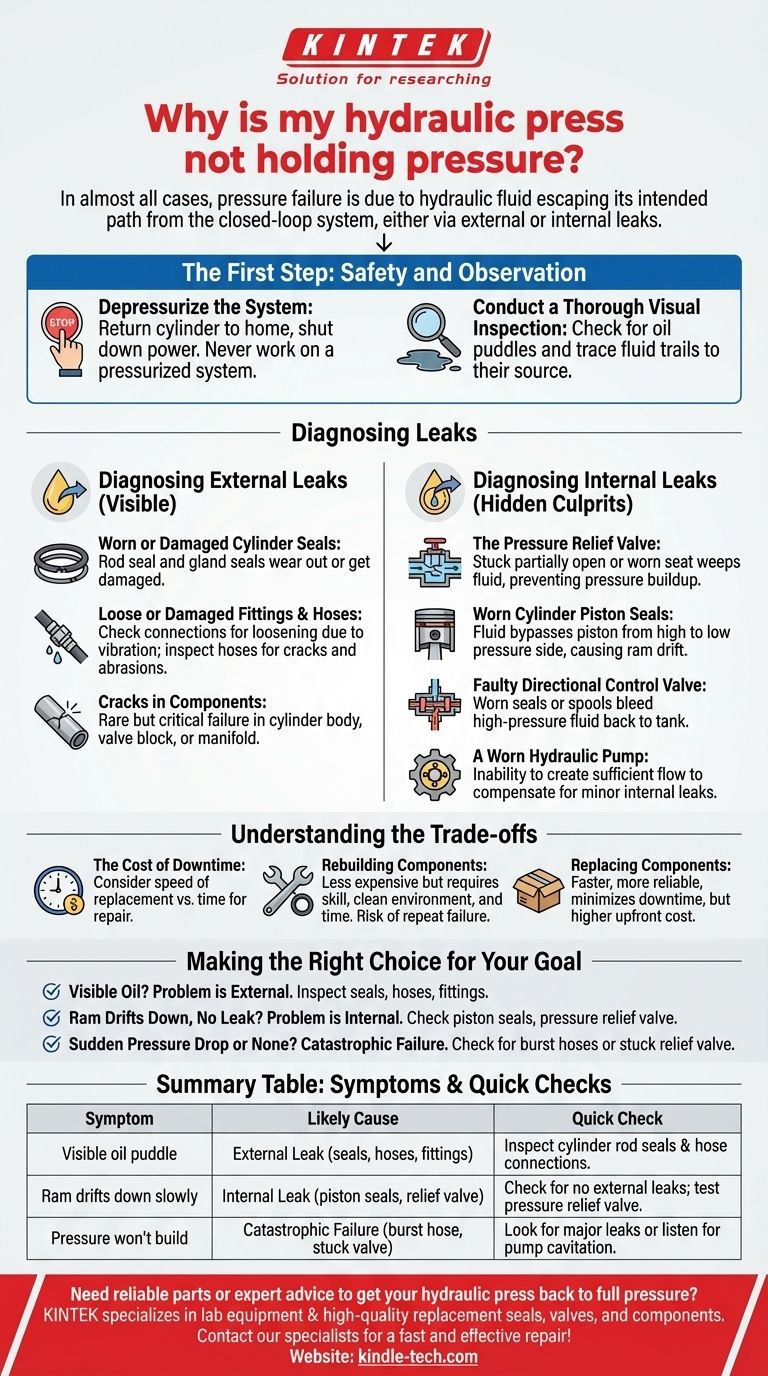

The First Step: Safety and Observation

Before you begin any diagnosis, you must ensure the situation is safe. Hydraulic systems store immense energy, and a sudden release can be extremely dangerous.

Depressurize the System

Always begin by completely depressurizing the system according to the manufacturer's instructions. This typically involves returning the cylinder to its home position and shutting down the power unit. Never work on a pressurized system.

Conduct a Thorough Visual Inspection

With the system off, carefully inspect the entire press. Look for puddles of hydraulic oil on the machine or the floor. Follow the fluid trails back to their source. The most obvious problem is often the correct one.

Diagnosing External Leaks

External leaks are the most common and easiest type of pressure loss to diagnose. The evidence is the leaking fluid itself.

Worn or Damaged Cylinder Seals

The seals around the cylinder rod (rod seal) and within the cylinder gland (gland seals) are primary suspects. Over time, these seals wear out, harden, or get damaged by contaminants, allowing fluid to seep out.

Loose or Damaged Fittings and Hoses

Vibration and pressure cycles can cause hydraulic fittings to loosen over time. Inspect every connection point. Hoses can also degrade, developing cracks or abrasions that result in leaks, especially where they flex or rub against the machine frame.

Cracks in Components

While less common, a crack in the cylinder body, a valve block, or a manifold will cause a significant leak and a major loss of pressure. This represents a critical component failure.

Diagnosing Internal Leaks (The Hidden Culprits)

If you see no external evidence of a leak but the press ram slowly "drifts" down or loses pressure under load, the leak is internal. Fluid is bypassing its correct path inside a component.

The Pressure Relief Valve

The pressure relief valve is a safety device designed to protect the system from over-pressurization by shunting excess flow back to the tank. If this valve is stuck partially open or its seat is worn, it will constantly "weep" fluid, preventing the system from reaching or holding its set pressure.

Worn Cylinder Piston Seals

The piston seal is what allows pressure to build on one side of the cylinder piston. If this seal is worn, fluid will leak from the high-pressure side to the low-pressure side inside the cylinder. This causes the ram to drift down under load with no external signs of a leak.

Faulty Directional Control Valve

The directional control valve directs fluid to extend or retract the cylinder. If the internal seals or spools within this valve are worn, they can allow high-pressure fluid to leak directly back to the tank or to the opposite side of the circuit, bleeding off system pressure.

A Worn Hydraulic Pump

A worn pump cannot create sufficient flow to compensate for even minor internal leaks. While the pump doesn't "hold" pressure (that's the job of the valves and seals), its inability to deliver required flow can manifest as an inability for the system to build or maintain pressure.

Understanding the Trade-offs

Once you've identified the faulty component, you must decide whether to repair or replace it. This decision is not just about cost.

The Cost of Downtime

The primary consideration is often the cost of having the machine out of service. A quick replacement gets you running faster, while a repair may take longer.

Rebuilding Components

Rebuilding a cylinder or valve with a seal kit is often less expensive in terms of parts. However, it requires a clean environment, specialized knowledge, and time. An incorrect rebuild will fail again quickly.

Replacing Components

Replacing a component entirely with a new or remanufactured one is faster and generally more reliable. It costs more upfront but minimizes downtime and the risk of a repeat failure due to workmanship errors.

Making the Right Choice for Your Goal

Your diagnostic path should be guided by the symptoms you observe.

- If your primary symptom is visible oil: Your problem is an external leak. Start by inspecting all seals, hoses, and fittings for the source.

- If the press ram drifts down with no visible leak: Your problem is an internal leak. Suspect the cylinder's piston seals or a leaking pressure relief valve first.

- If pressure drops suddenly or won't build at all: Check for a catastrophic failure like a burst hose or a pressure relief valve that is stuck wide open.

A systematic approach to troubleshooting is the key to a fast, safe, and effective repair.

Summary Table:

| Symptom | Likely Cause | Quick Check |

|---|---|---|

| Visible oil puddle | External Leak (seals, hoses, fittings) | Inspect cylinder rod seals and hose connections. |

| Ram drifts down slowly | Internal Leak (piston seals, relief valve) | Check for no external leaks; test pressure relief valve. |

| Pressure won't build | Catastrophic Failure (burst hose, stuck valve) | Look for major leaks or listen for pump cavitation. |

Need reliable parts or expert advice to get your hydraulic press back to full pressure? KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-quality replacement seals, valves, and components. Our team can help you diagnose the issue accurately and provide the right solution to minimize your downtime. Contact our hydraulic specialists today for a fast and effective repair!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy