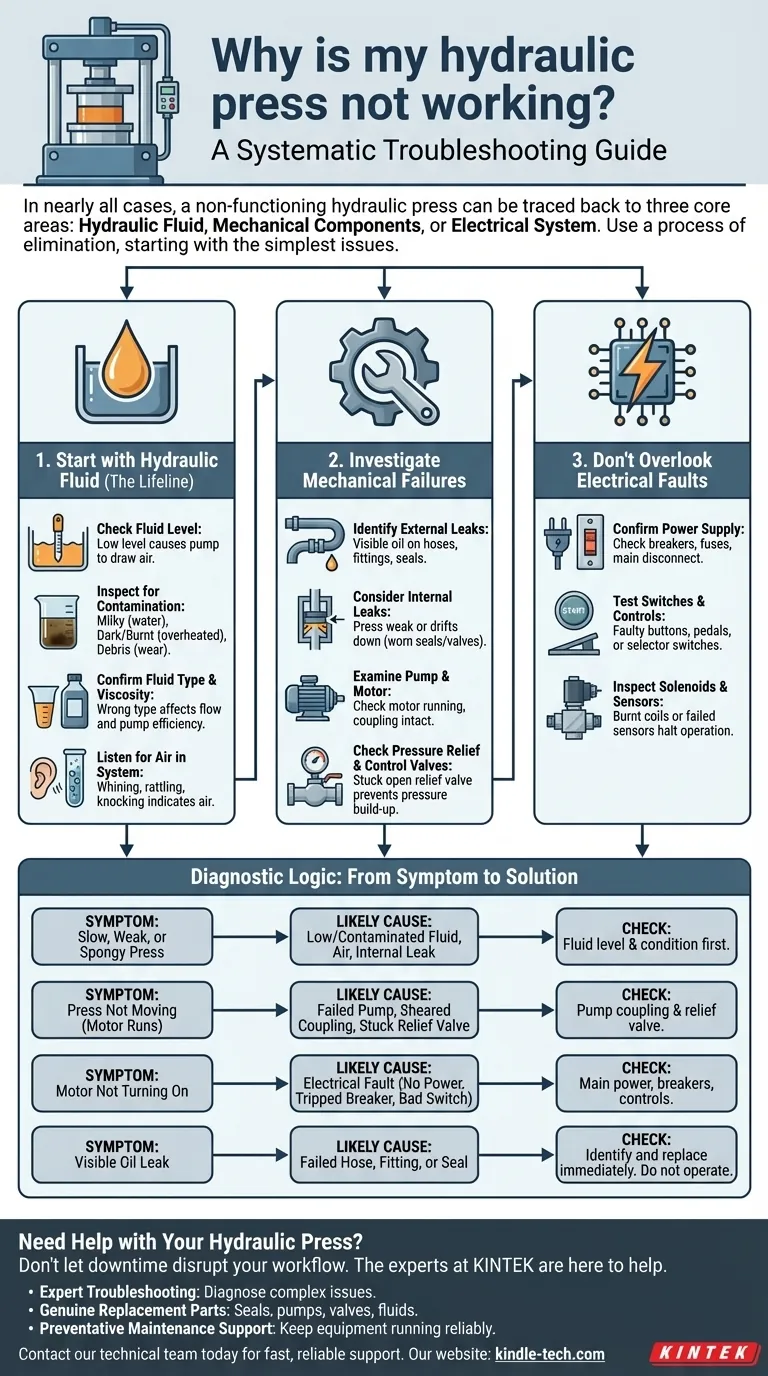

In nearly all cases, a non-functioning hydraulic press can be traced back to one of three core areas: the hydraulic fluid itself, a mechanical component failure, or an electrical system fault. While issues like fluid leaks are common culprits, a systematic process of elimination is the most effective way to pinpoint the exact cause of the failure and restore operation.

When a hydraulic press fails, the problem is rarely a complete mystery. By methodically checking the system's fluid, mechanical components, and electrical inputs—starting with the simplest and most common issues first—you can efficiently diagnose the root cause.

A Systematic Approach to Diagnosis

A hydraulic press is a powerful but straightforward machine. Its failure points are well-understood. Resist the urge to disassemble major components and instead begin with simple, external observations.

Start with the Hydraulic Fluid: The System's Lifeline

The fluid is the most critical and often most neglected part of the system. Problems here are the leading cause of poor performance and outright failure.

Check the Fluid Level

The most common cause of a press not working is a low hydraulic fluid level in the reservoir. A low level can cause the pump to draw in air instead of oil, preventing it from building pressure.

Inspect for Contamination

Look at the fluid's condition. If it appears milky, it likely has water contamination. If it's dark and smells burnt, it has overheated and degraded. Debris or particles indicate internal component wear or a failing filter. Contaminated fluid can clog valves and damage pumps.

Confirm Fluid Type and Viscosity

Using the wrong type of hydraulic fluid can drastically affect performance. Fluid that is too thick (high viscosity) may not flow properly, especially when cold, while fluid that is too thin (low viscosity) can reduce pump efficiency and increase wear.

Listen for Air in the System

If the pump makes a loud whining, rattling, or knocking noise, you likely have air in the system. This can be caused by a low fluid level or a leak on the pump's suction side. Air in the fluid (aeration or cavitation) prevents the system from building a solid, steady pressure.

Investigating Mechanical Failures

If the fluid appears to be in good condition, the next step is to inspect the physical components of the press for damage or wear.

Identify External Leaks

A visible pool of oil on the floor is an obvious sign of trouble. Carefully inspect all hoses, fittings, and seals around the cylinder and pump. A significant leak will prevent the system from reaching its required operating pressure.

Consider Internal Leaks

A press can be weak or drift down under load even with no visible leaks. This often points to an internal leak, typically caused by worn seals inside the main cylinder or a malfunctioning control valve that is allowing fluid to bypass its intended path.

Examine the Pump and Motor

Ensure the electric motor is running and that the coupling between the motor and the hydraulic pump is intact. A sheared coupling or a failed pump will result in a complete loss of function, even if the motor is humming.

Check Pressure Relief and Control Valves

The pressure relief valve is a safety device that can sometimes get stuck open, constantly dumping fluid back to the tank and preventing any pressure from building. Similarly, a directional control valve could be stuck or failing to shift, preventing fluid from reaching the cylinder.

Don't Overlook Electrical Faults

Before assuming a major mechanical failure, always verify the electrical system that controls the hydraulics.

Confirm Power Supply

This is the simplest check. Ensure the machine has power, check for tripped circuit breakers or blown fuses, and verify that the main power disconnect is switched on.

Test Switches and Controls

Operator controls like push-buttons, foot pedals, and selector switches can wear out over time. A faulty "start" button or a broken wire can make the machine appear completely dead.

Inspect Solenoids and Sensors

Modern presses use electric solenoids to actuate the hydraulic valves. If a solenoid coil burns out or its connection is loose, the valve it controls will not function. Likewise, failed pressure switches or position sensors can halt the machine's operation.

Understanding the Key Trade-offs

The inherent characteristics of hydraulic systems directly relate to their common failure modes. Understanding these helps in preventative maintenance.

The High Cost of Neglected Maintenance

Hydraulic systems require consistent upkeep. Because they rely on clean fluid and tight seals, neglecting filter changes and fluid analysis inevitably leads to component wear, leaks, and eventual failure. This need for maintenance is a primary "disadvantage" that becomes a reality when ignored.

The Inevitability of Fluid Leakage

The potential for fluid leaks is an accepted reality of high-pressure hydraulics. Seals, O-rings, and hoses are consumable parts that degrade over time. Proactive inspection for small seeps and weeps is critical to preventing the large-scale leaks that shut a press down.

Pressure Regulation as a Diagnostic Clue

Every hydraulic press has its pressure regulated by a relief valve. While this limits the machine's maximum force, a failure to reach any pressure often points directly to this valve being stuck open or set incorrectly. It becomes a key diagnostic checkpoint.

Making the Right Diagnosis

Use this logic to narrow down the problem based on the symptoms your press is exhibiting.

- If your primary symptom is a slow, weak, or spongy press: Your first suspect is the fluid. Check the fluid level, look for signs of air (foaming, noisy pump), and inspect for internal leaks.

- If your primary symptom is the press not moving at all (but the motor runs): Your focus should be on the pump, the coupling between the motor and pump, or a primary pressure relief valve that is stuck wide open.

- If your primary symptom is the motor not turning on at all: You have an electrical problem. Start with the main power supply, breakers, and operator controls before inspecting internal wiring or components.

- If your primary symptom is a visible oil leak: Do not operate the press. Your immediate priority is to identify the source of the leak and replace the failed hose, fitting, or seal.

By approaching the problem methodically, you can move from symptom to solution with confidence and precision.

Summary Table:

| Symptom | Likely Cause | First Thing to Check |

|---|---|---|

| Slow, Weak, or Spongy Press | Low/Contaminated Fluid, Air in System, Internal Leak | Hydraulic fluid level and condition |

| Press Not Moving (Motor Runs) | Failed Pump, Sheared Coupling, Stuck Relief Valve | Pump coupling and pressure relief valve |

| Motor Not Turning On | Electrical Fault (No Power, Tripped Breaker, Bad Switch) | Main power supply, circuit breakers, and operator controls |

| Visible Oil Leak | Failed Hose, Fitting, or Seal | Identify and replace the leaking component immediately |

Need Help with Your Hydraulic Press?

Don't let equipment downtime disrupt your workflow. The experts at KINTEK are here to help you get back to full production quickly.

We provide:

- Expert Troubleshooting: Our team can help diagnose complex hydraulic issues.

- Genuine Replacement Parts: We supply high-quality seals, pumps, valves, and fluids to ensure a lasting repair.

- Preventative Maintenance Support: Keep your lab equipment running reliably with our maintenance solutions and consumables.

KINTEK specializes in lab equipment and consumables, serving all your laboratory needs.

Contact our technical team today for fast, reliable support and keep your lab operating at peak performance.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis