In short, sintering is easier in the presence of a liquid phase because the liquid acts as a transport medium and lubricant at the atomic level. It allows solid particles to rearrange into a denser configuration, dissolves material from high-pressure contact points, and redeposits it into the gaps between particles, drastically accelerating densification and lowering the required process temperature.

The fundamental advantage of liquid phase sintering is its efficiency. By introducing a small amount of a liquid that wets the solid particles, you create a superhighway for material transport, enabling densification processes that are exceptionally slow and energy-intensive in a purely solid state.

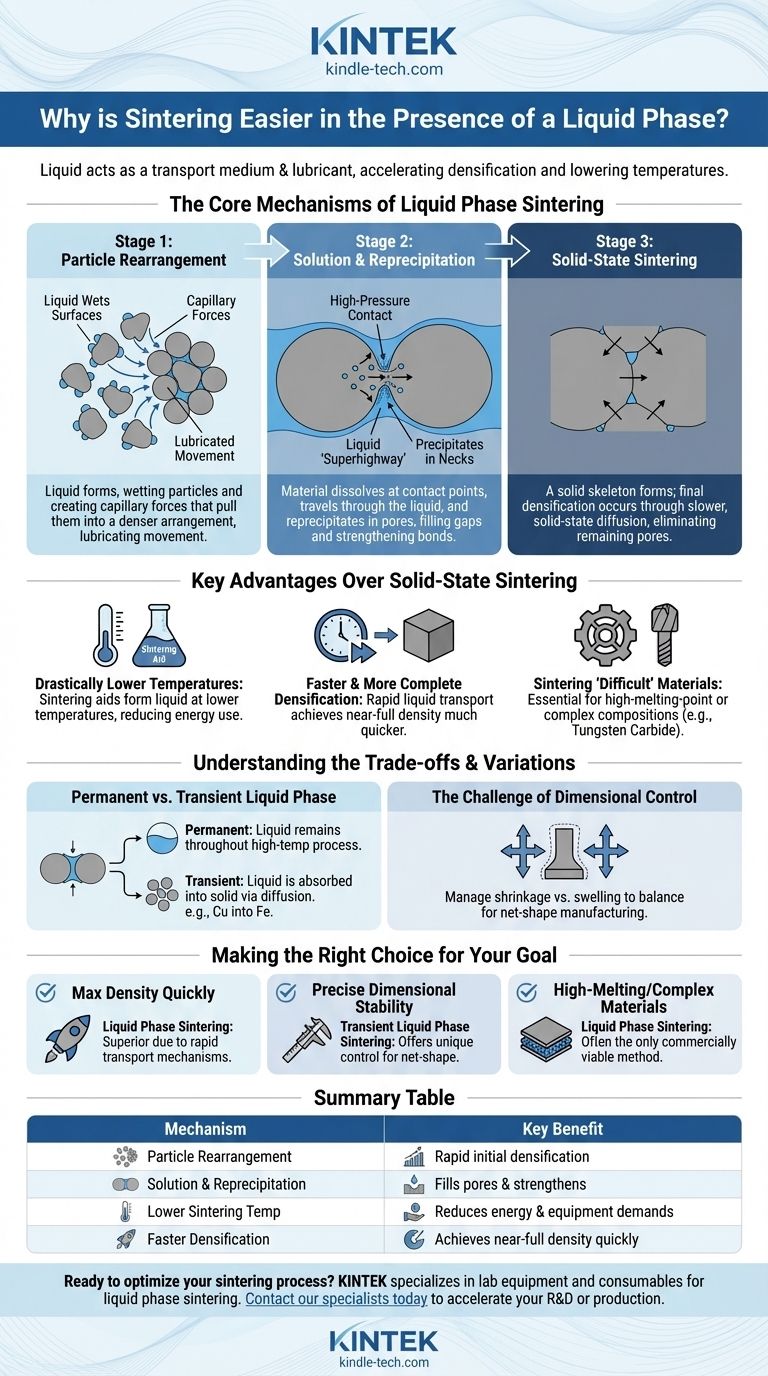

The Core Mechanisms of Liquid Phase Sintering

To understand why this process is so effective, we need to break down the stages that occur once the liquid forms at the sintering temperature.

Stage 1: Particle Rearrangement

The initial formation of a liquid has an immediate and powerful effect. The liquid wets the surfaces of the solid powder particles, creating powerful capillary forces.

These forces pull the particles together, essentially lubricating their movement. The solid grains slide and repack into a much denser arrangement than what could be achieved with dry powder, significantly reducing the porosity of the material right from the start.

Stage 2: Solution and Reprecipitation

This is the most critical stage for achieving full density. The solid material has some solubility in the liquid phase, especially at the high-pressure contact points between particles.

Material dissolves from these contact points and enters the liquid. It then travels through the liquid "superhighway" and precipitates (re-solidifies) in the low-pressure areas, specifically in the "necks" or gaps forming between adjacent particles. This process directly fills the pores, strengthens the bonds between particles, and shrinks the component.

Stage 3: Solid-State Sintering

In the final stage, a solid skeleton has formed, and most of the pore space has been eliminated. Any remaining densification occurs through slower, solid-state diffusion mechanisms, similar to conventional sintering, but the bulk of the work has already been done by the liquid.

Key Advantages Over Solid-State Sintering

The mechanisms above deliver several clear, practical benefits that make the process "easier" from an engineering perspective.

Drastically Lower Sintering Temperatures

By adding a small amount of a sintering aid—an additive with a lower melting point than the primary material—a liquid can be formed at temperatures far below the melting point of the main powder. This reduces energy consumption and allows for the use of less demanding furnace equipment.

Faster and More Complete Densification

Material transport through a liquid is orders of magnitude faster than through a solid lattice. This means that liquid phase sintering can achieve near-full density in a much shorter time compared to solid-state methods, improving throughput and process efficiency.

Sintering "Difficult" Materials

The process is indispensable for materials that are very difficult to sinter conventionally. This includes materials with extremely high melting points (like tungsten carbide) or complex multi-material compositions where solid-state diffusion is ineffective.

Understanding the Trade-offs and Variations

While powerful, liquid phase sintering is not a universal solution and requires careful control.

Permanent vs. Transient Liquid Phase

There are two primary modes. In permanent liquid phase sintering, a liquid is present throughout the high-temperature portion of the process.

In transient liquid phase sintering, the liquid forms initially but is then absorbed into the solid particles through diffusion. A classic example is adding copper powder to iron. The copper melts, facilitates rearrangement, and then diffuses into the iron, providing solid solution strengthening.

The Challenge of Dimensional Control

The material transport and densification inherent to the process cause the part to shrink. However, some systems, like the iron-copper example, can also cause swelling as the liquid diffuses into the solid.

This effect can be a challenge to manage, but it can also be expertly manipulated. By carefully selecting the composition, engineers can balance the natural shrinkage with this swelling to produce parts with near-zero dimensional change during sintering.

Making the Right Choice for Your Goal

Selecting the right sintering approach depends entirely on your material system and desired outcome.

- If your primary focus is achieving maximum density quickly: Liquid phase sintering is almost always the superior choice due to its rapid material transport mechanisms.

- If your primary focus is precise dimensional stability: Transient liquid phase sintering offers unique control, allowing you to balance shrinkage and swelling for net-shape manufacturing.

- If your primary focus is processing high-melting-point or complex materials: Liquid phase sintering is often the only commercially viable method to achieve the required density and properties.

Ultimately, using a liquid phase transforms sintering from a slow, solid-state crawl into a rapid, highly effective manufacturing process.

Summary Table:

| Mechanism | Key Benefit |

|---|---|

| Particle Rearrangement | Rapid initial densification via capillary forces. |

| Solution & Reprecipitation | Fills pores and strengthens bonds quickly. |

| Lower Sintering Temperature | Reduces energy consumption and equipment demands. |

| Faster Densification | Achieves near-full density in a shorter time. |

Ready to optimize your sintering process?

Liquid phase sintering is a powerful technique for achieving high-density components from hard-to-sinter materials like tungsten carbide or complex multi-material compositions. At KINTEK, we specialize in providing the precise lab equipment and consumables needed to master this process, from furnaces that maintain exact thermal profiles to the right sintering aids.

Our experts can help you select the ideal setup to leverage the benefits of liquid phase sintering—whether your goal is maximum density, precise dimensional control, or processing challenging materials.

Contact our sintering specialists today to discuss how we can enhance your laboratory's capabilities and accelerate your R&D or production.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the challenges of biomass production? Overcoming High Costs, Logistics, and Sustainability

- What is the purpose of reactive sputtering? Synthesize High-Performance Compound Thin Films

- What are the safety precautions for a water bath? Essential Guidelines for Lab Safety and Efficiency

- Is pyrolysis oil a biofuel? Understanding Its Potential as a Renewable Energy Source

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is the role of stirring equipment in the sol-gel coating process? Ensure Perfect Core-Shell Structures

- Which is a disadvantage of the carburizing process? High Costs, Complex Control, and Post-Processing Demands

- How is hot forging different from cold forging? Key Differences in Strength, Cost & Applications