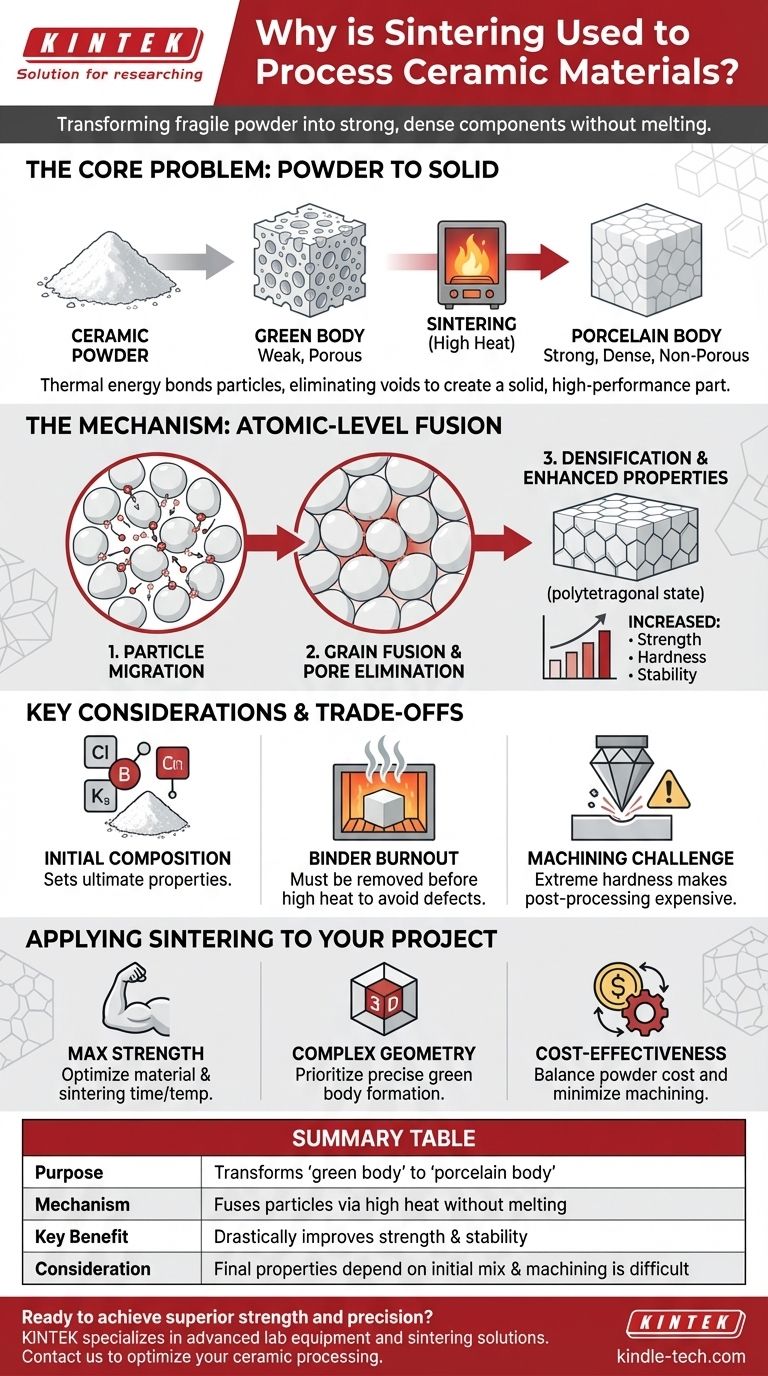

In short, sintering is the essential process used to transform a fragile object made of compressed ceramic powder into a hard, dense, and strong final part. This is achieved by applying high heat—without melting the material—which causes the individual ceramic particles to fuse together, eliminating the empty spaces between them and fundamentally enhancing the material's properties.

Sintering solves the core challenge of ceramics manufacturing: how to create a solid, high-performance component from a loose powder. It uses thermal energy to bond particles and drastically reduce porosity, which is the primary mechanism for developing the strength, hardness, and stability that make ceramics so valuable.

The Core Problem: Turning Powder into a Solid Component

Ceramics do not start as a liquid that can be poured into a mold. They begin as a fine powder, presenting a fundamental manufacturing challenge. Sintering is the bridge from that powdered state to a functional, solid object.

The Starting Point: The "Green Body"

First, the ceramic powder is mixed with binders and water to form a slurry, which is then dried and pressed into a desired shape. This initial, fragile piece is known as a "green body."

While it has the correct shape, the green body is mechanically weak and highly porous, held together only by the compaction force and temporary binders. It has none of the properties of a finished ceramic part.

The End Goal: A Dense, Strong "Porcelain Body"

The objective is to convert the porous green body into a dense, non-porous, and strong final piece, often called a "porcelain body." This densification is the single most important outcome of the sintering process and is directly responsible for the material's final strength.

The Mechanism: How Heat Creates Structure Without Melting

Sintering is a process of atomic-level fusion. Unlike melting, it works by encouraging solid particles to bond together through carefully controlled heat, often just below the material's melting point.

Activating Particle Migration

When the green body is heated to high temperatures, the atoms at the contact points between ceramic particles gain enough energy to move. This phenomenon is called material migration.

The atoms rearrange themselves to minimize surface energy, causing the boundaries between individual particles (or "grains") to merge. The particles essentially begin to fuse into one another.

Fusing Grains and Eliminating Pores

As the grains fuse, the small voids or pores between them are gradually filled in and closed off. This process of densification reduces the overall porosity of the object, making it much more solid and compact.

For some materials like zirconia, this transformation is dramatic. Sintering changes its crystalline structure from a monoclinic state to an extremely hard and dense polytetragonal state, unlocking its exceptional performance characteristics.

Enhancing Material Properties

Reducing porosity is directly linked to improved mechanical properties. A dense, sintered ceramic part is significantly stronger, harder, and more chemically stable than its unsintered counterpart. Properties like optical translucency can also be improved as internal voids that scatter light are removed.

Understanding the Trade-offs and Key Considerations

While powerful, the sintering process involves critical choices and constraints that dictate the success and cost of manufacturing a ceramic part.

The Initial Powder Composition is Critical

The final properties of the sintered part—its strength, hardness, and thermal stability—are determined by the initial mix of powdered materials. The chemistry of the starting powder sets the ultimate potential of the finished component.

The Process Is More Than Just Heat

Sintering is the final, crucial step in a multi-stage process. It includes preparing the slurry, forming the green body, and, critically, a lower-temperature heating cycle to burn off the temporary binders. If binders are not fully removed before high-temperature sintering, they can cause defects in the final part.

The Challenge of Post-Sintering Machining

The extreme hardness of a finished ceramic part is a major advantage in its final application but a significant challenge in manufacturing.

Once sintered, the part is so hard that it can typically only be machined or finished using specialized, costly methods like diamond tools or ultrasonic drilling. This makes dimensional accuracy in the "green" stage highly important to minimize expensive post-processing.

Applying This to Your Project

Your approach to ceramic sintering should be guided by your primary design goal.

- If your primary focus is maximal strength and hardness: Prioritize material selection (e.g., zirconia) and achieving near-full densification by optimizing the sintering temperature and time.

- If your primary focus is creating complex geometries: Pay close attention to the green body formation process (pressing, molding) to get as close to the final shape as possible, as post-sintering machining is difficult and expensive.

- If your primary focus is cost-effectiveness: Balance the cost of the raw ceramic powder with the required final properties, and design the part to minimize the need for post-sintering grinding or machining.

Ultimately, understanding sintering is understanding how to unlock the inherent potential of ceramic materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | Transforms fragile 'green body' into a dense, strong 'porcelain body' |

| Mechanism | Applies high heat to fuse ceramic particles without melting, reducing porosity |

| Key Benefit | Drastically improves strength, hardness, and chemical stability |

| Consideration | Final properties depend on initial powder; post-sintering machining is difficult |

Ready to achieve superior strength and precision in your ceramic components?

KINTEK specializes in advanced lab equipment and consumables for ceramic processing, including sintering solutions. Our expertise ensures you get the right tools to optimize material selection, green body formation, and sintering parameters for your specific project—whether your goal is maximum strength, complex geometries, or cost-effectiveness.

Contact us today to discuss how KINTEK can support your laboratory's ceramic manufacturing needs and help you unlock the full potential of your materials.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the uses of silicon carbide ceramics in different industries? Master Extreme Performance in Aerospace, Semiconductors & More

- What is another name for dental ceramic? Discover the Porcelain & Modern Material Options

- What is the application of SiC for energy? Revolutionizing Power Electronics for Maximum Efficiency

- What is zirconia in biomedical applications? A High-Strength, Biocompatible Ceramic for Implants

- What is the use of SiC semiconductor? Unlock Higher Efficiency for EVs and Power Systems

- Why is silicon carbide more efficient? Unlock Higher Power Density with SiC's Superior Material Properties

- What are the useful applications of ceramics? Unlock High-Performance Solutions for Your Industry

- What is the purpose of sintering ceramics? Transform Powder into Durable, High-Performance Parts