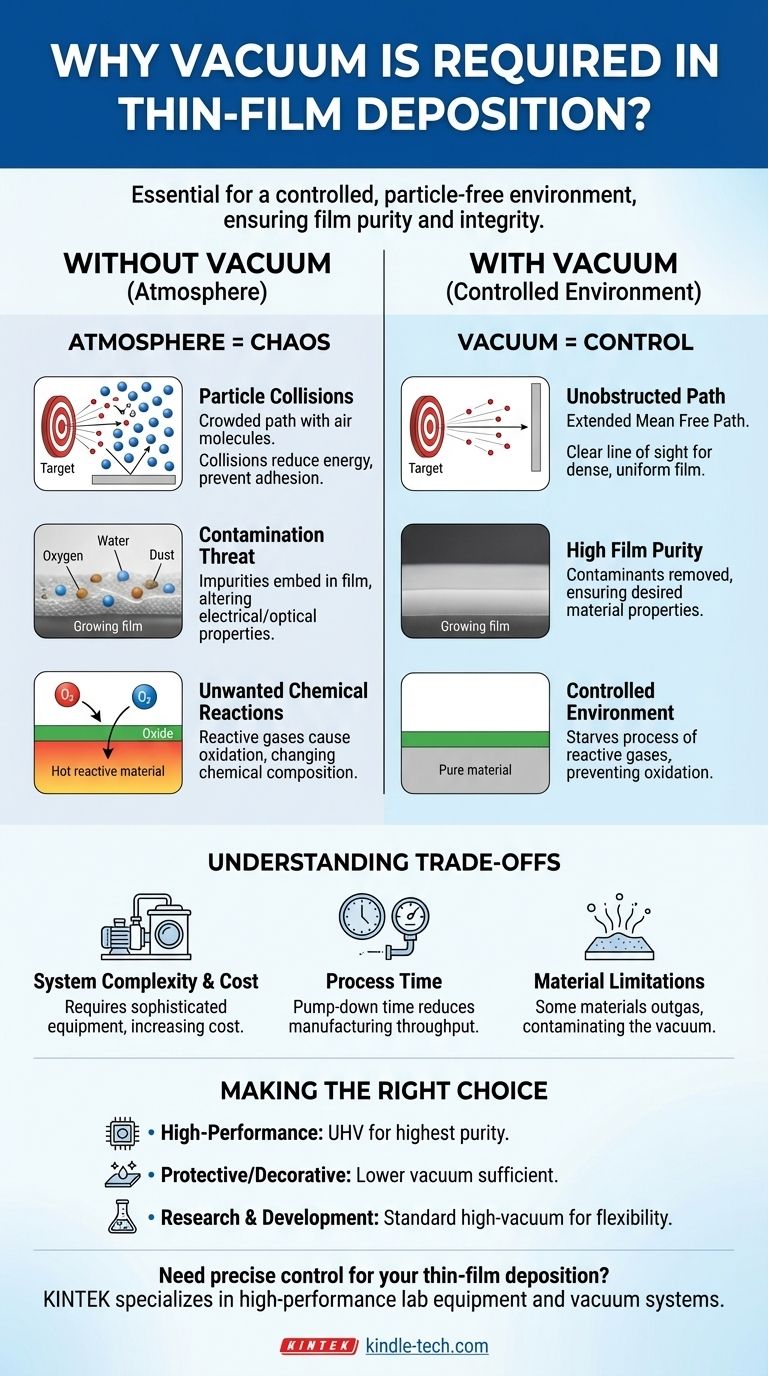

In thin-film deposition, a vacuum is essential to create a highly controlled, particle-free environment inside a deposition chamber. This is not an optional step but a fundamental requirement. The vacuum ensures that particles of the desired material can travel from their source to the substrate without colliding with or reacting to atoms from the air, guaranteeing the purity and structural integrity of the resulting film.

The core purpose of a vacuum is not merely to remove air, but to gain absolute control over the process environment. This control is what enables the creation of pure, dense, and predictable thin films with the specific electrical, optical, or mechanical properties required for advanced devices.

Why an Atmosphere Prevents Quality Film Growth

To understand the need for a vacuum, we must first recognize that our normal atmosphere is a dense, reactive soup of particles. For a process occurring at the nanometer scale, this atmospheric environment is chaotic and completely unsuitable for precision work.

The Problem of Particle Collisions

Deposited particles must travel from a source (the "target") to a destination (the "substrate"). In a standard atmosphere, this path is crowded with billions of nitrogen, oxygen, and water molecules.

The material particles ejected from the source will inevitably collide with these atmospheric gas molecules. Each collision deflects the particle and reduces its energy, preventing it from reaching the substrate or arriving with insufficient energy to form a dense, well-adhered film.

This concept is defined by the mean free path—the average distance a particle can travel before hitting another particle. In a vacuum, the mean free path is extended from nanometers to many meters, creating a clear, unobstructed "line of sight" from the source to the substrate.

The Threat of Contamination

Thin films are defined by their purity. Even minuscule amounts of unintended materials can drastically alter their performance.

Atmospheric air contains oxygen, water vapor, nitrogen, and dust. If these particles are present during deposition, they will become embedded in the growing film.

This contamination can ruin the film's desired properties. For example, an unintended oxygen atom in a conductive film can decrease its conductivity, while impurities in an optical coating can reduce its transparency. Achieving high film purity is impossible without first removing these atmospheric contaminants.

The Risk of Unwanted Chemical Reactions

Many materials used in thin-film deposition are highly reactive, especially when heated to the high temperatures common in these processes.

The most common and detrimental reaction is oxidation. If oxygen is present in the chamber, it will readily react with the hot deposition material, forming an unintended oxide layer instead of the pure material intended.

This fundamentally changes the chemical composition of your film, turning a pure metal layer, for example, into a less conductive or even insulating metal oxide. A vacuum environment starves the process of these reactive gases.

Understanding the Trade-offs of a Vacuum Environment

While essential, creating and maintaining a vacuum is not without its challenges. Recognizing these trade-offs is key to understanding process design and manufacturing limitations.

System Complexity and Cost

Achieving a high vacuum requires sophisticated and expensive equipment. This includes a sealed chamber and a series of pumps, such as a mechanical "roughing" pump to remove the bulk of the air and a high-vacuum pump (like a turbomolecular or cryogenic pump) to remove the remaining molecules. This adds significant cost and complexity to any deposition system.

Process Time and Throughput

Reaching the required vacuum level is not instantaneous. The time it takes to pump the chamber down to the target pressure is known as the pump-down time.

For ultra-high vacuum (UHV) systems, this can take several hours. This non-productive time directly impacts manufacturing throughput, creating a bottleneck in high-volume production environments.

Material Limitations

Not all materials are suitable for high-vacuum environments. Some materials, particularly polymers or those with high vapor pressure, can "outgas," releasing trapped gases when placed under vacuum. This can contaminate the process and make it difficult to reach the desired vacuum level.

Making the Right Choice for Your Goal

The required level of vacuum is directly tied to the acceptable level of impurity for your final application. A more demanding application requires a better (lower pressure) vacuum.

- If your primary focus is high-performance electronics or optics: You must use a high or ultra-high vacuum (UHV) to guarantee the highest film purity and prevent any performance degradation.

- If your primary focus is protective or decorative coatings: A lower-quality vacuum may be sufficient, as microscopic impurities are less likely to affect the bulk mechanical or aesthetic properties.

- If your primary focus is research and development: A standard high-vacuum system offers the best balance of cleanliness, flexibility, and operational cost for experimenting with new materials and processes.

Ultimately, the vacuum is the invisible foundation upon which the quality and reliability of any advanced thin-film device are built.

Summary Table:

| Aspect | Without Vacuum | With Vacuum |

|---|---|---|

| Particle Travel | Collisions with air molecules | Unobstructed path to substrate |

| Film Purity | Contaminated by oxygen, water, dust | High purity, minimal impurities |

| Chemical Reactions | Unwanted oxidation and reactions | Controlled, reaction-free environment |

| Film Properties | Unpredictable, degraded performance | Consistent electrical, optical, mechanical properties |

Need precise control over your thin-film deposition process? At KINTEK, we specialize in high-performance lab equipment, including vacuum systems tailored for thin-film deposition. Whether you're in R&D or manufacturing, our solutions ensure the purity, density, and reliability your applications demand. Contact us today to discuss how we can optimize your deposition environment for superior results!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method