Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

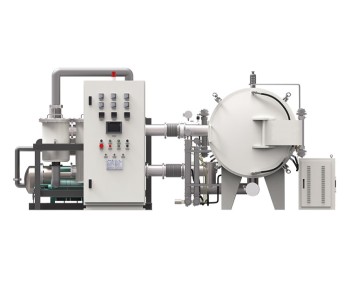

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Custom PTFE Teflon Parts Manufacturer for F4 PTFE Volumetric Bottle

Item Number : PTFE-25

Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

Item Number : KM-P03

High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

Item Number : KM-P02

Custom PTFE Teflon Parts Manufacturer for Microwave Digestion Tank

Item Number : PTFE-37

Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

Item Number : PTFE-36

Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

Item Number : PTFE-35

Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

Item Number : PTFE-34

Custom PTFE Teflon Parts Manufacturer Grinding Bowl

Item Number : PTFE-33

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

Item Number : PTFE-32

Custom PTFE Teflon Parts Manufacturer F4 Conical Flask Triangular Flask 50 100 250ml

Item Number : PTFE-31

Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

Item Number : PTFE-30

Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

Item Number : PTFE-29

Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

Item Number : PTFE-28

Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

Item Number : PTFE-27

Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

Item Number : PTFE-26

Custom CVD Diamond Coating for Lab Applications

Item Number : cvdm-05

Custom PTFE Teflon Parts Manufacturer Laboratory High Temperature Mixing Paddle Mixer

Item Number : PTFE-23

Custom PTFE Teflon Parts Manufacturer for Sampling Solution Sample and Dry Powder Spoons

Item Number : PTFE-22

Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

Item Number : PTFE-21

Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

Item Number : PTFE-20

Versatile PTFE Solutions for Semiconductor and Medical Wafer Processing

Item Number : PTFE-18

Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

Item Number : PTFE-16

Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

Item Number : PTFE-14

CVD Diamond Optical Windows for Lab Applications

Item Number : cvdm-08

Laboratory CVD Boron Doped Diamond Materials

Item Number : cvdm-07

CVD Diamond Domes for Industrial and Scientific Applications

Item Number : cvdm-06

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Silent Vessel: Why the Material of Your Furnace Tube Defines Your Science

The tube furnace tube is not just a container; it is a boundary condition. Learn how choosing between ceramic, quartz, and metal defines your experimental limits.

The Geometry of Cleanliness: Why Surface Integrity Defines Electrochemical Success

Master the art of electrolytic cell maintenance. Discover how a tiered cleaning protocol prevents contamination and ensures experimental reproducibility.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

The Art of the Finish: Why the Most Critical Moment Happens After the Data is Collected

The experiment isn't over when the data is saved. Learn the psychological and technical art of shutting down and cleaning optical electrolytic cells.

The Architecture of Certainty: Mastering Control in Multifunctional Electrolytic Cells

Precision in electrochemistry isn't about guesswork; it's about hardware architecture. Learn how the three-electrode system isolates variables for true control.

The Architecture of Isolation: Anatomy of a Tube Furnace

Explore the layered engineering of a tube furnace. From alumina insulation to quartz reactors, understand how this "thermal sleeve" achieves precise isolation.

The Hidden Life of Lab Equipment: Preserving the Integrity of the Electrolytic Cell

Proper storage is an active defense against entropy. Learn the protocols for maintaining electrolytic cells to ensure data fidelity and equipment longevity.

The Silent Interface: Mastery Over Electrode Decay

Electrode failure is rarely sudden; it is the compound interest of neglect. Learn the disciplined maintenance protocols that preserve accuracy and longevity.

The Silent Partner: Why Material Choice in Electrochemistry is a Matter of Trust

Discover why high borosilicate glass and PTFE are the non-negotiable standards for electrolytic cells. A deep dive into material science for precise data.

The Art of the Non-Spontaneous: Precision in Electrolytic Circuits

Mastering the electrolytic cell setup requires more than connecting wires. It demands a systematic approach to polarity, purity, and power control.

The Invisible Geography of Heat: Why "Max Temperature" is a Trap

In thermal processing, maximum temperature is often a vanity metric. Discover why the "Uniform Heated Zone" is the true architect of repeatability.

Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

Frustrated by failed experiments? Learn why your furnace tube material—not your process settings—is the critical variable causing inconsistent results.

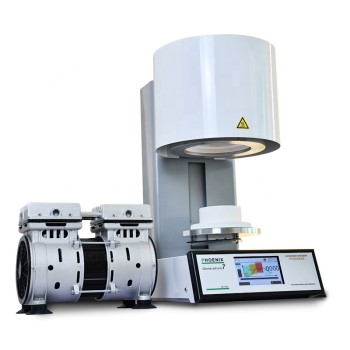

How to Select the Right Oil-Free Diaphragm Pump for Your Lab or Industrial Needs

Learn how to choose the right oil-free diaphragm pump for your lab or industry—balancing specs, chemical resistance, and lifetime costs.

How to Choose Laboratory Vacuum Pumps for Maximum Efficiency and Cost Savings

Learn how to choose the right lab vacuum pump for efficiency & cost savings. Compare oil-sealed vs. oil-free pumps & future-proof your investment.

Water Circulating Vacuum Pumps: A Practical Guide for Laboratory Applications

Discover the benefits of water circulating vacuum pumps for labs: chemical safety, low maintenance, and explosion-proof operation. Ideal for sensitive applications.

How to Choose Crucible Materials That Prevent Chemical Degradation in Vacuum Induction Melting

Learn how to choose crucible materials for vacuum induction melting to prevent chemical degradation and optimize alloy purity. Essential guide for industrial applications.

How ULT Freezers Protect Scientific Discoveries in Genetics and Drug Development

ULT freezers safeguard genetic and pharmaceutical research by maintaining -80°C storage for DNA, proteins, and cell lines—preventing sample degradation and ensuring research validity.

Preserving the Irreplaceable: How ULT Freezers Protect Critical Samples Across Industries

ULT freezers at -80°C protect biological samples, vaccines, and research materials from degradation, ensuring long-term viability across industries.

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

Explore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.

Performance and application of polytetrafluoroethylene (PTFE) in high temperature environment