Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

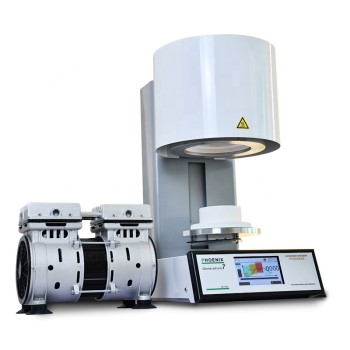

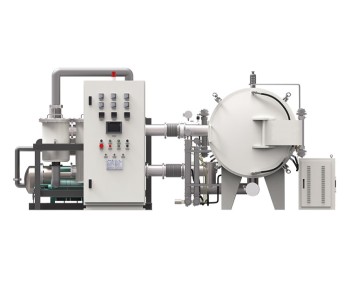

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

High Purity Zinc Foil for Battery Lab Applications

Item Number : BC-15

CVD Diamond Cutting Tool Blanks for Precision Machining

Item Number : cvdm-04

CVD Diamond Wire Drawing Die Blanks for Precision Applications

Item Number : cvdm-03

CVD Diamond for Thermal Management Applications

Item Number : cvdm-02

CVD Diamond Dressing Tools for Precision Applications

Item Number : cvdm-01

Nickel Foam for Industrial and Laboratory Applications

Item Number : BC-24

Iridium Dioxide IrO2 for Water Electrolysis

Item Number : BC-22

Anion Exchange Membrane for Laboratory Use

Item Number : BC-21

Proton Exchange Membrane for Batteries Lab Applications

Item Number : BC-20

Lithium Battery Tab Tape for Battery Lab Applications

Item Number : BC-19

Polyethylene Separator for Lithium Battery

Item Number : BC-18

High-Purity Titanium Foil and Sheet for Industrial Applications

Item Number : BC-17

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Item Number : BC-16

Custom PTFE Teflon Parts Manufacturer for Air Valve Applications

Item Number : PTFE-08

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

Item Number : BC-14

Aluminum Foil Current Collector for Lithium Battery

Item Number : BC-13

Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

Item Number : BC-12

Nickel Aluminum Tabs for Soft Pack Lithium Batteries

Item Number : BC-11

Button Battery Storage Box for Battery Lab

Item Number : BC-10

Platinum Sheet Electrode for Battery Lab Applications

Item Number : BC-09

Li-Air Battery Case for Battery Lab Applications

Item Number : BC-04

Cylindrical Battery Steel Case for Battery Lab

Item Number : BC-03

Button Battery Case Gasket for Battery Lab Applications

Item Number : BC-02

Button Battery Case for Battery Lab Applications

Item Number : BC-01

Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

Item Number : PTFE-12

Custom PTFE Teflon Parts Manufacturer for PTFE Containers

Item Number : PTFE-11

Custom PTFE Teflon Parts Manufacturer for Sampling Filters

Item Number : PTFE-10

Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

Item Number : PTFE-09

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

The Geometry of Cleanliness: Why Surface Integrity Defines Electrochemical Success

Master the art of electrolytic cell maintenance. Discover how a tiered cleaning protocol prevents contamination and ensures experimental reproducibility.

The Thermodynamics of Patience: Preventing Electrolytic Cell Overload

Overloading an electrolytic cell isn't just an error; it's a systemic failure. Learn the physics of safety, the risks of excess energy, and how to maintain control.

The Real Reason Your Sintered Parts Crack (And It’s Not the Furnace)

Stop blaming the furnace. Discover the hidden flaw in powder pressing that causes parts to crack and learn how Cold Isostatic Pressing (CIP) offers a permanent fix.

The Silent Interface: Mastery Over Electrode Decay

Electrode failure is rarely sudden; it is the compound interest of neglect. Learn the disciplined maintenance protocols that preserve accuracy and longevity.

The Silence of the Seal: Why Electrochemical Precision is a Battle Against the Atmosphere

Precision in electrochemistry isn't just about voltage; it's about isolation. Discover how super-sealed cells defeat contamination and define reproducibility.

The Silent Partner: Why Material Choice in Electrochemistry is a Matter of Trust

Discover why high borosilicate glass and PTFE are the non-negotiable standards for electrolytic cells. A deep dive into material science for precise data.

The Architecture of Control: Why Thermal Stability Defines Electrolysis Success

Discover how double-layer water-bath electrolytic cells eliminate thermal variables, ensuring accuracy and reproducibility in electrochemical research.

Why Your High-Temperature Furnace Elements Keep Failing (And How to Stop It)

Discover the hidden causes of MoSi2 heating element failure, like pesting and chemical attack, and learn how to achieve reliable, repeatable results.

Why Your High-Temperature Furnace Elements Fail: The Critical Difference in Silicon Carbide

Furnace downtime from failing SiC heating elements costs time and money. Discover the critical material difference that ensures reliability in extreme applications.

How to Select the Right Oil-Free Diaphragm Pump for Your Lab or Industrial Needs

Learn how to choose the right oil-free diaphragm pump for your lab or industry—balancing specs, chemical resistance, and lifetime costs.

Preserving the Irreplaceable: How ULT Freezers Protect Critical Samples Across Industries

ULT freezers at -80°C protect biological samples, vaccines, and research materials from degradation, ensuring long-term viability across industries.

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

Explore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.

Performance and application of polytetrafluoroethylene (PTFE) in high temperature environment

PTFE seals: the invisible guardian of industrial leakage prevention

PTFE Seals are used to prevent liquid or gas leakage and are widely used in valves, pumps, and piping systems.

PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

The unique advantages of polytetrafluoroethylene (PTFE) in high temperature and corrosion resistance analyze why it has become an indispensable material in industry, especially in applications in harsh environments.

Innovative Application of PTFE in Mechanical Seals

PTFE has become one of the core materials in the field of mechanical seals due to its unique chemical stability, low friction coefficient (0.04-0.15), wide temperature range (-268°C to +315°C) and excellent corrosion resistance (pH 0-14).

The key role of PTFE in semiconductor manufacturing: from gas pipelines to electrical insulation

From high-purity gas delivery pipelines to precision electrical insulation components, the multi-faceted application of PTFE in the semiconductor industry chain provides important guarantees for the purity, stability and reliability of the manufacturing process.

How to use PTFE to improve the working efficiency of pumps and valves

Polytetrafluoroethylene (PTFE) has become a key material for improving the efficiency of pumps and valves due to its unique physical and chemical properties.

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.