Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

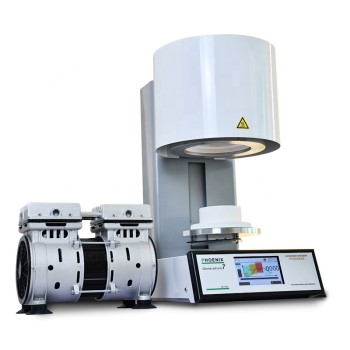

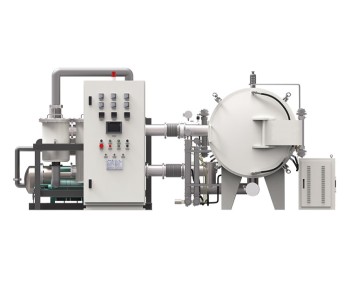

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

Item Number : PTFE-07

Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

Item Number : PTFE-06

Custom PTFE Teflon Parts Manufacturer for Gaskets and More

Item Number : PTFE-05

Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

Item Number : PTFE-04

Custom PTFE Teflon Parts Manufacturer for Conductive Glass Substrate Cleaning Rack

Item Number : PTFE-03

Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

Item Number : KME01-2

Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

Item Number : KM-DG05

Silicon Carbide (SIC) Ceramic Plate for Engineering Advanced Fine Ceramics

Item Number : KM-DG03

Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

Item Number : KM-DG02

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Item Number : KM-G04

Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

Item Number : KM-G03

Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

Item Number : KM-P01

Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

Item Number : KM-C013

Wall Mounted Water Distillation Unit

Item Number : KT-C01

High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

Item Number : KM-C06

Advanced Engineering Fine Ceramics Alumina Ceramic Saggar for Fine Corundum

Item Number : KM-C05

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

The Art of Nothing: Why Critical Engineering Demands Vacuum Brazing

Discover how vacuum furnace brazing eliminates oxidation for superior joint integrity, the physics of vapor pressure, and why material selection dictates the process.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

The Art of the Finish: Why the Most Critical Moment Happens After the Data is Collected

The experiment isn't over when the data is saved. Learn the psychological and technical art of shutting down and cleaning optical electrolytic cells.

The Architecture of Isolation: Anatomy of a Tube Furnace

Explore the layered engineering of a tube furnace. From alumina insulation to quartz reactors, understand how this "thermal sleeve" achieves precise isolation.

Why Your Heat-Treated Parts Are Failing: The Hidden Enemy in Your Furnace

Seeing inconsistent results from your furnace? Learn why air is the real culprit in heat treatment and how to get perfect, oxide-free parts every time.

The Hidden Life of Lab Equipment: Preserving the Integrity of the Electrolytic Cell

Proper storage is an active defense against entropy. Learn the protocols for maintaining electrolytic cells to ensure data fidelity and equipment longevity.

Why Your Brazed Joints Fail: The Truth About Furnace Temperature and How to Master It

Discover the root cause of inconsistent brazing results. It's not the furnace, but a misunderstanding of how temperature relates to filler metals.

The Architecture of Control: Why Thermal Stability Defines Electrochemical Precision

Master electrochemical accuracy by understanding the interplay between three-electrode systems and thermal regulation. Eliminate variables to ensure reproducibility.

The Architecture of Invisible Containment: Why Material Choice Defines Electrochemical Precision

Explore the strategic engineering behind High Borosilicate Glass and PTFE in electrolytic cells—balancing visibility with absolute chemical inertness.

The Thermodynamics of Precision: Mastering the Double-Layer Electrolytic Cell

Precision isn't accidental. Discover the methodical operation of double-layer electrolytic cells, where thermal stability and rigid setup define success.

Inconsistent Melts? The Problem Isn't Your Furnace, It's the Physics.

Struggling with inconsistent alloy quality and high costs? Discover the hidden reason and learn how to choose the right furnace for perfect results.

Your Induction Furnace Is Failing You. The Reason Isn't What You Think.

Struggling with inconsistent melts or high costs? The problem may be a fundamental mismatch in your induction furnace type. Learn to fix it.

The Architecture of Control: Why Thermal Stability Defines Electrolysis Success

Discover how double-layer water-bath electrolytic cells eliminate thermal variables, ensuring accuracy and reproducibility in electrochemical research.

Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

Tired of failed experiments from cracked ceramic tubes? Learn the real reason it happens and how to select the correct material (Alumina, Quartz) for your lab.

Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

Frustrated by failed experiments? Learn why your furnace tube material—not your process settings—is the critical variable causing inconsistent results.

Furnace Contamination: The Hidden Saboteur Ruining Your High-Value Parts

Discover why your heat-treating process fails on high-value parts. The issue isn't your settings—it's hidden furnace contamination. Learn the fix.

Why Your High-Temperature Furnace Elements Fail: The Critical Difference in Silicon Carbide

Furnace downtime from failing SiC heating elements costs time and money. Discover the critical material difference that ensures reliability in extreme applications.

How to Select the Right Oil-Free Diaphragm Pump for Your Lab or Industrial Needs

Learn how to choose the right oil-free diaphragm pump for your lab or industry—balancing specs, chemical resistance, and lifetime costs.

How to Choose Laboratory Vacuum Pumps for Maximum Efficiency and Cost Savings

Learn how to choose the right lab vacuum pump for efficiency & cost savings. Compare oil-sealed vs. oil-free pumps & future-proof your investment.