Toggle Categories

Get Instant Support

Choose your preferred way to connect with our team

-

Get Free Quote Fill out form for detailed pricing

-

Send Email Detailed inquiry support

-

WhatsApp Quick mobile chat

Response Time

Within 8 hours on working days, 24 hours on holidays

Sample Preparation

KinTek sample preparation equipment includes sample crushing,milling, as while as while sieving equipment, hydraulic press equipment includes manual press, electric press, isostatic press, hot press and press filtering machine.

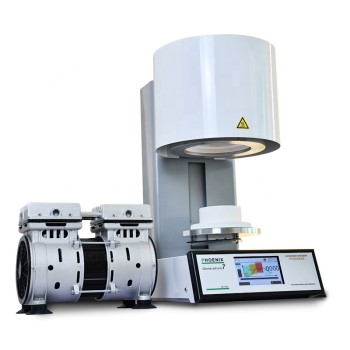

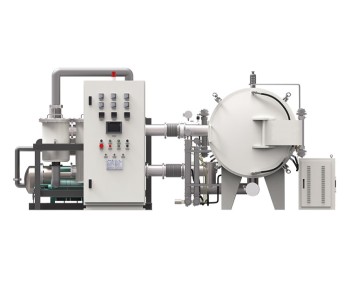

Thermal Equipment

KinTek supplies a broad range of high-temperature furnaces, including lab, pilot production, and industrial production furnaces, with a temperature range of up to 3000 ℃. One of KinTek's advantages is the ability to create custom-made furnaces tailored to specific functions, such as different heating methods and speeds, extra high and dynamic vacuums, controlled atmospheres and gas circuits, automated mechanical structures, and software and hardware development.

Lab Consumables & Materials

KinTek offers a range of lab consumables and materials, including evaporation materials, targets, metals, electrochemistry parts, as well as powders, pellets, wires, strips, foils, plates, and more.

Bio-Chem Equipment

KinTek bio-chem equipment comprises rotary evaporators, glass and stainless steel reactors, distillation systems, circulating heaters and chillers, as well as vacuum equipment.

Products

Infrared High Resistance Single Crystal Silicon Lens

Item Number : KTOM-HBS

Carbon Graphite Plate Manufactured by Isostatic Pressing Method

Item Number : KM-D11

Carbon Graphite Boat -Laboratory Tube Furnace with Cover

Item Number : KM-D10

Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

Item Number : KM-D9

Custom Boron Nitride (BN) Ceramic Parts

Item Number : KM-D8

Boron Nitride (BN) Ceramic Plate

Item Number : KM-D7

Boron Nitride (BN) Ceramic Tube

Item Number : KM-D5

Hexagonal Boron Nitride HBN Thermocouple Protection Tube

Item Number : KM-D02

400-700nm Wavelength Anti Reflective AR Coating Glass

Item Number : KTOM-ARG

Optical Window Glass Substrate Wafer Sheets Zinc Sulfide ZnS Window

Item Number : KTOM-ZSS

Infrared Thermal Imaging Temperature Measurement Double-Sided Coated Germanium Ge Lens

Item Number : KTOM-CGL

Infrared Transmission Coating Sapphire Sheet Substrate Window

Item Number : KTOM-ISS

Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

Item Number : KTOM-ZSW

High Purity Pure Graphite Crucible for Electron Beam Evaporation

Item Number : KMS02

Shortpass Filters for Optical Applications

Item Number : KTOM-SLS

XRD Sample Holder X-ray Diffractometer Powder Slide

Item Number : KTOM-XRD

Longpass Highpass Filters for Optical Applications

Item Number : KTOM-LHF

Narrow Band Pass Filters for Precision Applications

Item Number : KTOM-NBF

MgF2 Magnesium Fluoride Crystal Substrate Window for Optical Applications

Item Number : KTOM-MFS

Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

Item Number : KTOM-CFW

Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

Item Number : KME09

Optical Window Glass Substrate Wafer Barium Fluoride BaF2 Substrate Window

Item Number : KTOM-BFS

Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

Item Number : KTOM-CGS

Thermally Evaporated Tungsten Wire for High Temperature Applications

Item Number : KME08

Zooplankton Plankton Counting Chamber for Plankton Eggs and Ascaris Eggs

Item Number : KTOM-PAE

Float Soda-Lime Optical Glass for Laboratory Use

Item Number : KTOM-FSO

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Articles

The Fragile Intersection: Mastering the Side-Window Optical Electrolytic Cell

Spectroelectrochemistry combines chemical, electrical, and optical hazards in a delicate vessel. Here is how to master the safety and precision of this complex system.

The Ceramic Paradox: Why the Best Way to Clean an Alumina Tube is Not to Clean It

Deep cleaning is often a symptom of process failure. Discover the engineering protocols to maintain alumina tubes, prevent thermal shock, and ensure longevity.

The Silent Vessel: Why the Material of Your Furnace Tube Defines Your Science

The tube furnace tube is not just a container; it is a boundary condition. Learn how choosing between ceramic, quartz, and metal defines your experimental limits.

The Thermal Ceiling: Pushing 2200°C in Vacuum Environments

Discover how specialized vacuum furnaces achieve 2200°C+ through advanced graphite and tungsten elements. A deep dive into thermal engineering and material limits.

Entropy and the Alumina Tube: The Art of Precision Maintenance

Discover the disciplined approach to cleaning alumina furnace tubes. Learn how to prevent thermal shock, remove residue with acid, and extend equipment life.

The Architecture of Certainty: Mastering Control in Multifunctional Electrolytic Cells

Precision in electrochemistry isn't about guesswork; it's about hardware architecture. Learn how the three-electrode system isolates variables for true control.

The Geometry of Truth: Why the Maintenance of Your Optical Electrolytic Cell Defines Your Data

Great data isn't just about the experiment; it's about the vessel. Learn the rigorous maintenance protocols for side-window optical electrolytic cells.

The Silent Partner: Why Material Choice in Electrochemistry is a Matter of Trust

Discover why high borosilicate glass and PTFE are the non-negotiable standards for electrolytic cells. A deep dive into material science for precise data.

Why Your Ceramic Furnace Tubes Keep Cracking—And How to Choose the Right One

Tired of failed experiments from cracked ceramic tubes? Learn the real reason it happens and how to select the correct material (Alumina, Quartz) for your lab.

Cracked Tubes, Contaminated Samples? Your Furnace Tube Is The Hidden Culprit

Frustrated by failed experiments? Learn why your furnace tube material—not your process settings—is the critical variable causing inconsistent results.

Water Circulating Vacuum Pumps: A Practical Guide for Laboratory Applications

Discover the benefits of water circulating vacuum pumps for labs: chemical safety, low maintenance, and explosion-proof operation. Ideal for sensitive applications.

How to Choose Crucible Materials That Prevent Chemical Degradation in Vacuum Induction Melting

Learn how to choose crucible materials for vacuum induction melting to prevent chemical degradation and optimize alloy purity. Essential guide for industrial applications.

How Cascade Refrigeration Powers Ultra-Low Temperature Freezers Beyond Single-Stage Limits

Learn how cascade refrigeration enables ultra-low temperature freezers to reach -80°C and beyond, overcoming single-stage system limitations for critical sample storage.

Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

Explore the unique advantages of polytetrafluoroethylene (PTFE)'s low coefficient of friction and analyze how it promotes progress and innovation in industrial technology in terms of reducing wear and improving equipment efficiency.

PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

The unique advantages of polytetrafluoroethylene (PTFE) in high temperature and corrosion resistance analyze why it has become an indispensable material in industry, especially in applications in harsh environments.

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

Precision Ceramic Materials for Energy Conversion Applications

Overview of various ceramic materials used in energy conversion technologies, including heaters, piezoelectric ceramics, and solid oxide fuel cells.

Advanced Technologies for Precision Ceramics

Explores key technologies and preparation methods for precision ceramic components, highlighting their applications and challenges.

Precision Ceramics in Semiconductor Applications

Exploring the use of precision ceramics in semiconductor equipment, their properties, and manufacturing processes.

The 5 Hottest Advanced Ceramic Powders Currently Available!

An overview of the top 5 advanced ceramic powders: High Purity Aluminum Oxide, Boehmite, Aluminum Nitride, Silicon Nitride, and Spherical Alumina, highlighting their applications and market trends.