Evaporation Coating Technology

Resistance Evaporation

Resistance evaporation is a straightforward and cost-effective method for vaporizing materials with relatively low melting points, such as aluminum, gold, and silver. This technique leverages the principle of resistance heating, where an electric current is passed through a resistive element to generate heat, which in turn vaporizes the target material. The simplicity of this process is one of its primary advantages, making it accessible for various applications where high throughput is not a critical requirement.

However, resistance evaporation is not without its limitations. One significant drawback is its inability to efficiently vaporize materials with high melting points. This constraint arises because the heat generated by resistance heating may not be sufficient to melt and vaporize such materials, leading to inefficient processes and potentially incomplete coatings. Additionally, the evaporation rates in this method are generally lower compared to other advanced techniques, which can be a limiting factor in industrial applications requiring rapid deposition of coatings.

Despite these limitations, resistance evaporation remains a valuable tool in specific scenarios, particularly where the simplicity and cost-effectiveness of the process outweigh the need for high-speed or high-melting point material processing.

Electron Beam Evaporation

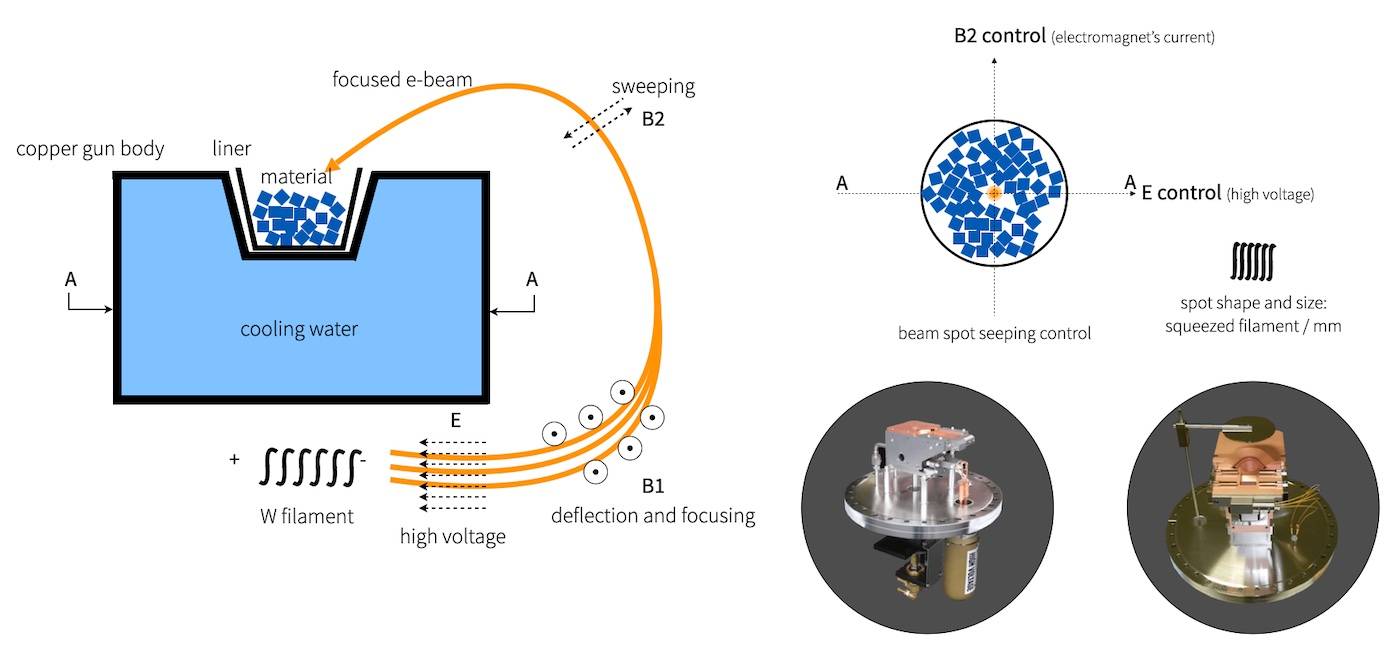

Electron beam evaporation utilizes a focused beam of high-energy electrons to directly heat and vaporize materials with high melting points, such as tungsten and germanium. This method employs an electron beam that is typically accelerated by a 100 kV DC voltage source, reaching temperatures around 3000 °C. The electrons are directed towards the target material, where they lose their kinetic energy rapidly upon impact, converting it into thermal energy that heats the material's surface. This localized heating ensures minimal contamination from the crucible, thereby maintaining high film purity.

The process involves the electrons being emitted from a filament, often positioned below the water-cooled copper hearth, and then accelerated through an extraction grid. The beam is bent through 270° before striking the melt, allowing for precise and localized heating. This method is particularly advantageous for materials that require extremely high temperatures for vaporization, as it is not limited by the melting point of the heating element.

However, electron beam evaporation is not without its challenges. The technology requires complex and costly drive electronics, which can limit its scalability compared to simpler methods like resistive evaporation. Despite these complexities, electron beam evaporation remains a powerful and controllable technology, particularly favored in applications such as ophthalmic coatings where high film purity and thermal efficiency are critical.

Induction Heating Evaporation

Induction heating evaporation is a sophisticated method that leverages high-frequency electromagnetic fields to induce currents within the source material. These induced currents generate heat, leading to the vaporization of the material. This technique stands out for its ability to achieve high evaporation rates and maintain temperature stability, making it particularly effective for materials that require precise thermal control.

However, the implementation of induction heating evaporation is not without its challenges. The high-frequency electromagnetic fields necessitate effective shielding to prevent interference with other electronic systems. Additionally, the equipment required for this process is both costly and complex, involving advanced technology and precise engineering to ensure optimal performance. Despite these drawbacks, the benefits of high evaporation rates and temperature stability make induction heating evaporation a valuable tool in the arsenal of vacuum coating technologies.

Sputtering Coating Technology

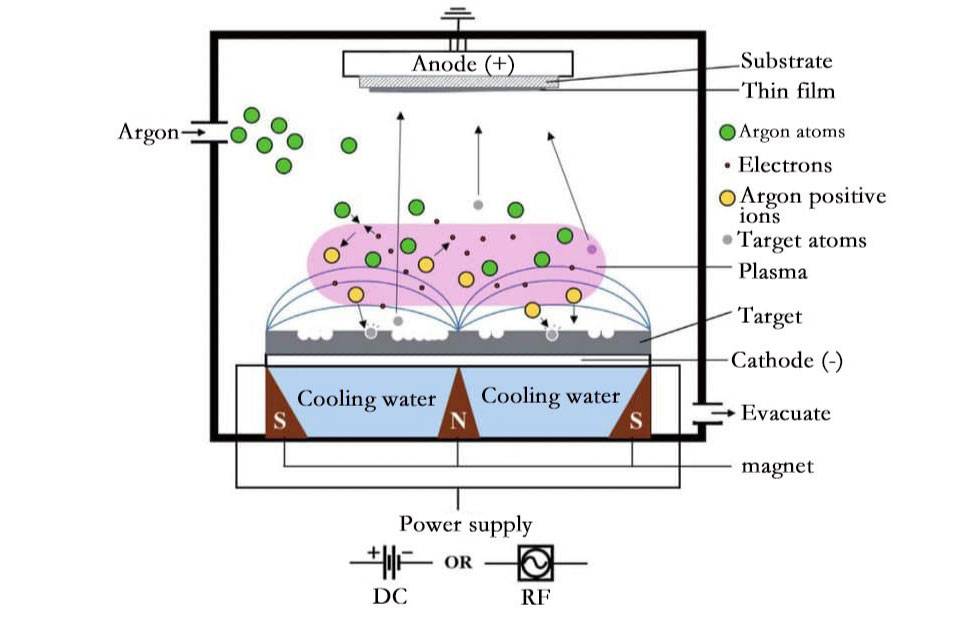

Magnetron Sputtering

Magnetron sputtering is a sophisticated plasma-based coating technique that excels in both reactive and non-reactive processes, affording precise control over film composition and thickness. This method leverages the collision of energetic ions, confined within a magnetic field, with a target material. This collision results in the ejection of atoms from the target, which are then deposited onto a substrate. The magnetic field not only enhances the efficiency of the process but also reduces gas incorporation and energy losses in the sputtered atoms, contributing to the production of high-quality films.

One of the standout features of magnetron sputtering is its high deposition rates and power efficiency. This makes it particularly suitable for applications requiring low substrate temperatures, which is a significant advantage over other physical vapor deposition (PVD) methods. However, the technology is not without its challenges. Target utilization remains a critical area of improvement, as the efficiency of material usage can be suboptimal. Despite this, the scalability and quality of films produced by magnetron sputtering make it a preferred choice in various industrial applications.

| Advantages | Challenges |

|---|---|

| High deposition rates | Target utilization efficiency |

| Power efficiency | |

| Suitable for low substrate temperatures | |

| High-quality film production | |

| Scalability compared to other PVD methods |

Ion Plating Technology

Vacuum Ion Coating Principles

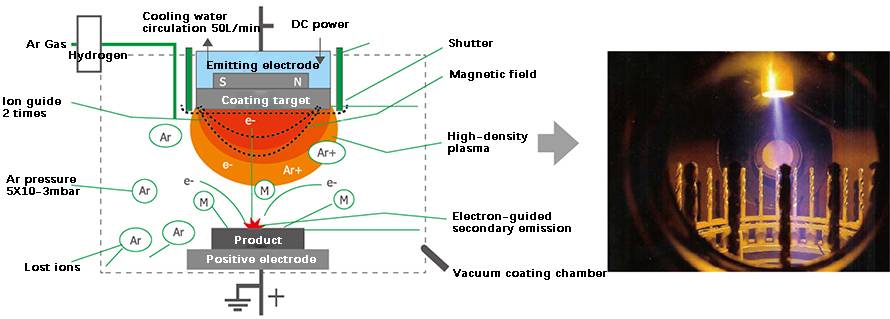

Vacuum ion plating is a sophisticated process that synergistically combines the principles of evaporation and sputtering, leveraging ion bombardment to significantly enhance the adhesion and overall quality of the deposited film. This method is particularly advantageous for coating complex geometries, where traditional techniques may fall short.

In vacuum ion plating, the target material is subjected to ion bombardment within a high-vacuum environment. These ions, which are atoms that have been electrically charged, are accelerated towards the target material, causing it to vaporize. The vaporized particles then travel through the vacuum and condense onto the substrate, forming a thin, high-quality film. This process, also known as ion beam-assisted deposition (IBAD), ensures that the film adheres more firmly to the substrate due to the increased energy with which the particles reach the surface.

One of the key advantages of ion plating over other physical vapor deposition (PVD) processes is its ability to deposit materials at lower temperatures and higher rates. This makes it particularly suitable for a wide range of materials, including those that are difficult to vaporize using traditional thermal evaporation or sputter deposition methods. However, it's worth noting that ion plating chambers are generally more expensive than those used for other PVD processes, reflecting the complexity and precision required for this advanced technique.

The process of vacuum ion plating can be broken down into several key steps:

- Target Material Placement: The target material is carefully placed within the vacuum chamber.

- Vacuum Creation: The chamber is evacuated to create a high-vacuum environment, essential for the successful execution of the process.

- Ion Bombardment: The target material is bombarded with ions, causing it to vaporize.

- Film Formation: The vaporized material condenses on the substrate to form a thin film.

- Purge and Completion: The chamber is purged with an inert gas to remove any residual vapors, completing the process.

This method not only ensures strong plating adhesion but also offers a robust plating capability, making it a preferred choice for applications requiring high-quality, durable coatings.

Types of Ion Plating

Ion plating encompasses a diverse array of techniques, each tailored to specific applications and material requirements. The primary methods can be broadly categorized into sputtering-type and evaporation-type ion plating. Within these categories, several specialized techniques have been developed to address particular challenges and enhance the properties of the deposited films.

Sputtering-Type Ion Plating

DC secondary ion plating is a notable variant within the sputtering-type category. This method involves the use of direct current (DC) power to generate ions that bombard the target material, facilitating the deposition process. The primary advantage of DC secondary ion plating lies in its ability to produce dense, adherent coatings with excellent surface finish. This technique is particularly well-suited for applications requiring high precision and durability, such as in the aerospace and automotive industries.

Hollow cathode ion plating represents another innovative approach within the sputtering-type ion plating family. This method employs a hollow cathode discharge to create a high-density plasma, which enhances the ion bombardment process. The result is a high deposition rate and superior film properties, making it ideal for applications like corrosion protection in nuclear reactors and decorative coatings.

Evaporation-Type Ion Plating

On the other hand, cathodic arc ion plating stands out as a prominent technique within the evaporation-type ion plating methods. This process utilizes a cathodic arc discharge to vaporize the target material, which is then deposited onto the substrate under the influence of energetic ion bombardment. The key advantage of cathodic arc ion plating is its ability to produce extremely thin, yet highly adherent and dense coatings. This makes it particularly valuable for applications requiring high-quality coatings on complex geometries, such as in the production of high-tolerance injection molds and aircraft engine turbine blades.

Plasma-Based Ion Plating

Plasma-based ion plating is a versatile technique that leverages the power of plasma to deposit a wide range of metals, including titanium, aluminum, copper, gold, and palladium. The coatings produced by this method typically range from 0.008 to 0.025 mm in thickness. One of the most significant advantages of plasma-based ion plating is its ability to tailor the properties of the deposited film, such as morphology, density, and residual film stress. This adaptability makes it suitable for a broad spectrum of applications, from X-ray tubes and steel drill bits to decorative coatings and corrosion protection in nuclear reactors.

| Ion Plating Type | Primary Advantages | Typical Applications |

|---|---|---|

| DC Secondary Ion Plating | Dense, adherent coatings with excellent surface finish | Aerospace, automotive industries |

| Hollow Cathode Ion Plating | High deposition rate, superior film properties | Corrosion protection in nuclear reactors, decorative coatings |

| Cathodic Arc Ion Plating | Extremely thin, highly adherent, and dense coatings | High-tolerance injection molds, aircraft engine turbine blades |

| Plasma-Based Ion Plating | Tailors film properties (morphology, density, residual stress) | X-ray tubes, steel drill bits, decorative coatings, corrosion protection |

Each of these ion plating techniques offers unique benefits and is selected based on the specific demands of the application, ensuring optimal performance and durability of the final product.

Material Selection and Applications

Material Compatibility

Ion plating stands out as a highly versatile vacuum coating technology, capable of accommodating a broad spectrum of materials, including metals, ceramics, plastics, glass, and semiconductors. Each material type brings its own set of challenges and benefits to the coating process, which directly influences the final performance of the coated product.

For instance, metals are often chosen for their excellent conductivity and mechanical strength, making them ideal for applications requiring robust and electrically conductive coatings. In contrast, ceramics offer superior hardness and chemical resistance, which are crucial for protective coatings in harsh environments. Plastics and glass, on the other hand, benefit from ion plating for enhancing their surface properties, such as durability and aesthetic appeal, without compromising their inherent characteristics.

The selection of the appropriate material is not merely a technical decision but a strategic one, driven by the specific demands of the application scenario. For example, in the electronics industry, semiconductors undergo ion plating to improve their electrical properties and surface finish, which are critical for device performance and reliability. Similarly, in the automotive sector, ion plating is used to enhance the corrosion resistance and wear-resistance of metal components, extending their service life and reducing maintenance costs.

| Material Type | Key Benefits | Application Examples |

|---|---|---|

| Metals | Excellent conductivity, mechanical strength | Electrical components, structural parts |

| Ceramics | High hardness, chemical resistance | Protective coatings, wear-resistant parts |

| Plastics | Enhanced surface properties, lightweight | Consumer goods, automotive interiors |

| Glass | Improved durability, aesthetic appeal | Architectural glass, optical components |

| Semiconductors | Improved electrical properties, surface finish | Electronic devices, integrated circuits |

The versatility of ion plating in handling diverse materials underscores its importance across various industries, making it a cornerstone technology in modern manufacturing processes.

Adhesion and Color Variations

The disparity in adhesion between evaporation and sputtering coatings is fundamentally rooted in the intrinsic characteristics of these processes. Evaporation, which involves heating materials to their vaporization point, typically results in coatings with lower adhesion compared to sputtering, where high-energy particles bombard the target material, causing it to dislodge and deposit on the substrate. This energetic deposition process enhances the bonding between the coating and the substrate, leading to superior adhesion.

Moreover, vacuum coating technology offers the capability to produce a spectrum of colors and achieve semi-transparency through meticulous control of the deposition parameters and the selection of specific materials. For instance, the manipulation of the deposition rate, the angle of incidence, and the use of multilayer coatings can significantly influence the optical properties of the final product. This versatility is particularly evident in applications requiring aesthetic or functional color variations, such as in the automotive and consumer electronics industries.

| Coating Technique | Adhesion Strength | Color Variability |

|---|---|---|

| Evaporation | Moderate | Limited |

| Sputtering | High | High |

In summary, while both evaporation and sputtering can achieve diverse visual effects, the underlying process mechanics dictate the adhesion strength and the potential for color variability. Sputtering, with its higher energy deposition, not only ensures better adhesion but also provides greater flexibility in color and transparency customization.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

- Electron Beam Evaporation Coating Gold Plating Tungsten Molybdenum Crucible for Evaporation

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

Related Articles

- Understanding PECVD: A Guide to Plasma-Enhanced Chemical Vapor Deposition

- Plasma Enhanced Chemical Vapor Deposition (PECVD): A Comprehensive Guide

- Advantages and Disadvantages of Chemical Vapor Deposition (CVD)

- A Comprehensive Guide to PECVD Equipment Maintenance

- A Step-by-Step Guide to the PECVD Process