Fundamentals of Film Deposition

Ion Bombardment

In the context of magnetron sputtering, the process of ion bombardment plays a pivotal role in the generation of thin films. Energetic ions, generated within the plasma, are accelerated towards the target material. This bombardment is not merely a physical impact but a complex interaction where the kinetic energy of the ions is transferred to the target atoms. As a result, atoms from the target surface are ejected, a phenomenon known as sputtering.

The intensity of ion bombardment is directly influenced by several factors, including the power applied to the magnetron, the configuration of the magnetic field, and the pressure of the working gas. Higher sputtering power typically increases the energy of the ions, enhancing the rate at which target atoms are sputtered out. However, this increase in power must be balanced to avoid excessive heating of the substrate, which could lead to detrimental effects on the film's structural integrity.

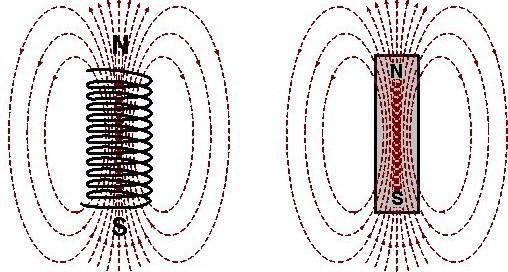

The magnetic field configuration, in particular, is crucial as it guides the plasma ions towards the target, creating a localized erosion pattern. Non-uniform magnetic fields can result in uneven sputtering, leading to variations in the thickness and quality of the deposited film. Therefore, optimizing the magnetic field setup is essential to ensure consistent ion bombardment and, consequently, uniform film deposition.

Moreover, the choice of working gas and its pressure significantly affects the plasma's behavior and the efficiency of ion bombardment. For instance, higher gas pressures can lead to a more diffuse plasma, reducing the precision of ion targeting and potentially causing instability in the deposition process. Conversely, lower pressures can enhance the focus of ion bombardment but may require adjustments in other parameters to maintain optimal sputtering conditions.

In summary, ion bombardment is a dynamic and intricate process that requires careful control of multiple variables to achieve the desired uniformity in thin film deposition. Each parameter—from sputtering power to magnetic field configuration and gas pressure—interacts in a complex manner, necessitating a holistic approach to optimization.

Atomic Migration

In the process of magnetron sputtering, the sputtered atoms do not immediately settle onto the substrate but instead undergo a complex migration process within the vacuum chamber. This migration is influenced by several factors, including the low-pressure environment, the kinetic energy imparted by the sputtering process, and the presence of residual gases.

The vacuum environment, typically maintained at pressures ranging from 10^-3 to 10^-6 Torr, allows the atoms to travel relatively long distances without significant collisions, enabling a more uniform distribution over the substrate surface. The kinetic energy of the sputtered atoms, which can range from a few tens to hundreds of electron volts, plays a crucial role in their migration. Higher energy atoms tend to migrate further and can penetrate deeper into the substrate, influencing the film's adhesion and structural integrity.

Residual gases present in the chamber, such as argon or oxygen, can interact with the migrating atoms, potentially leading to the formation of clusters or altering their trajectory. These interactions can be both beneficial and detrimental, depending on the desired film properties. For instance, the presence of oxygen can enhance the formation of oxides, which are crucial for certain functional films, but it can also lead to non-uniform deposition if not controlled properly.

The migration process is also affected by the magnetic field configuration within the sputtering chamber. The magnetic field, which traps electrons and enhances plasma formation, can create localized regions of higher and lower plasma density. This spatial variation in plasma density can influence the trajectory and deposition rate of the sputtered atoms, contributing to the overall uniformity of the deposited film.

In summary, the migration of sputtered atoms in a vacuum is a multi-faceted process that is influenced by the vacuum pressure, atomic kinetic energy, residual gas interactions, and magnetic field configuration. Understanding and controlling these factors is essential for achieving uniform thin film deposition in magnetron sputtering.

Film Formation

As the sputtered atoms traverse the vacuum chamber, they undergo a series of complex interactions before finally settling on the substrate. This deposition process is not instantaneous; rather, it occurs over a period of time, during which the atoms accumulate on the substrate surface. The initial layer of atoms adheres to the substrate, forming a nucleation layer that serves as the foundation for subsequent atomic layers.

The formation of a thin film is a dynamic process influenced by several factors, including the energy of the deposited atoms, the substrate temperature, and the presence of impurities. Atoms with higher kinetic energy are more likely to migrate across the substrate surface, leading to a more uniform distribution. Conversely, lower energy atoms tend to settle where they land initially, potentially causing localized thickness variations.

Substrate temperature plays a critical role in film formation. Elevated temperatures can enhance atomic mobility, promoting the formation of a more uniform film by allowing atoms to diffuse over greater distances. However, excessively high temperatures can also lead to undesirable effects such as substrate warping or the formation of voids within the film.

The presence of impurities, whether from the substrate surface or the deposition environment, can significantly impact film quality. Impurities can act as nucleation sites, leading to the formation of defects such as pinholes or grain boundaries. These defects can compromise the film's structural integrity and functional properties.

In summary, the formation of a thin film in magnetron sputtering is a multi-faceted process that involves the accumulation of atoms on the substrate, influenced by factors such as atomic energy, substrate temperature, and impurity levels. Understanding and controlling these factors is crucial for achieving uniform and high-quality thin film deposition.

Factors Affecting Uniformity

Equipment Parameters

The uniformity of thin film deposition in magnetron sputtering is significantly influenced by several critical equipment parameters. These parameters include the target size and shape, the distance between the target and the substrate, and the rotation and oscillation of the target. Each of these factors plays a unique role in determining the consistency and quality of the deposited film.

Target Size and Shape

The size and shape of the target material are foundational elements in the sputtering process. A larger target can accommodate a wider range of substrate sizes, but it also requires more precise control to ensure uniform sputtering. The shape of the target, whether planar or cylindrical, can affect the distribution of sputtered atoms. For instance, a planar target typically results in a more uniform distribution compared to a cylindrical one, which may require additional mechanisms to achieve similar uniformity.

Distance Between Target and Substrate

The distance between the target and the substrate is another crucial parameter. This distance directly impacts the path length of the sputtered atoms as they travel from the target to the substrate. A shorter distance can result in a higher deposition rate but may also lead to uneven distribution due to shadowing effects. Conversely, a longer distance can improve uniformity but may reduce the deposition rate. Therefore, an optimal distance must be carefully calibrated to balance these competing factors.

Rotation and Oscillation of the Target

To further enhance uniformity, the target can be rotated or oscillated during the sputtering process. Rotation ensures that the entire surface of the target is utilized evenly, preventing localized depletion and extending the target's lifespan. Oscillation, on the other hand, can help distribute the sputtered atoms more uniformly across the substrate, particularly in cases where the target is not perfectly planar. These mechanical movements are essential for achieving consistent film thickness across the substrate, especially for large or irregularly shaped substrates.

In summary, optimizing these equipment parameters is vital for achieving high-quality, uniform thin films through magnetron sputtering. Each parameter must be carefully considered and adjusted to ensure the best possible outcomes in terms of film uniformity and quality.

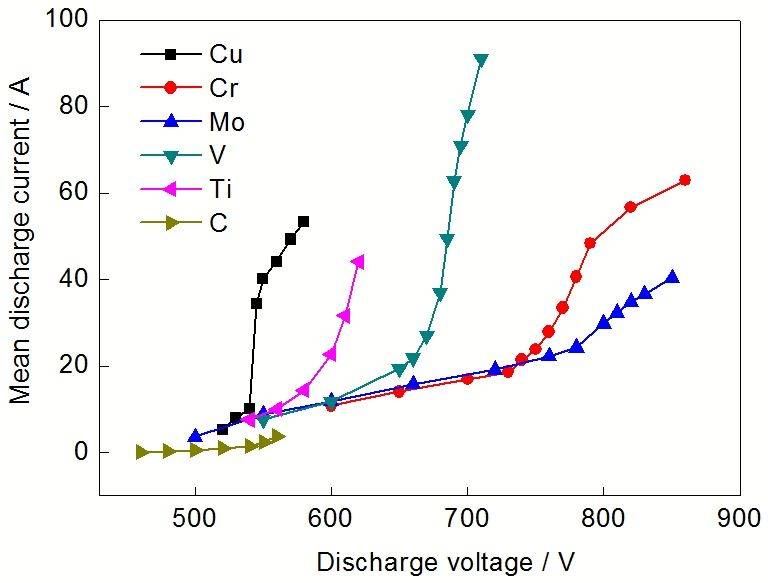

Sputtering Power

Sputtering power is a critical parameter in the magnetron sputtering process, directly influencing the intensity of ion bombardment on the target material. The power applied to the sputtering system accelerates ions within the plasma, which then collide with the target surface. As the energy of these ions increases, they penetrate deeper into the target material's atomic structure, causing more atoms to be ejected from the surface.

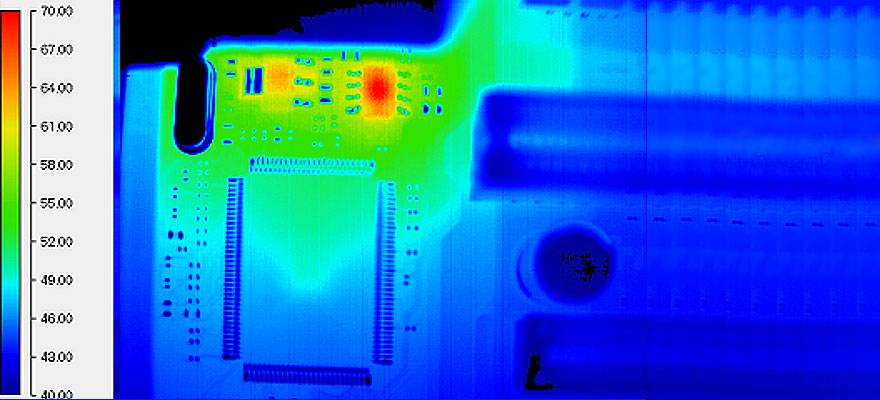

Higher sputtering power not only enhances the deposition rate but also introduces potential challenges. For instance, an elevated power level can lead to increased substrate temperatures, which may affect the structural integrity and adhesion of the deposited film. The balance between achieving a high deposition rate and maintaining optimal substrate conditions is crucial for uniform film formation.

| Sputtering Power Level | Effect on Process |

|---|---|

| Low Power | Reduced ion bombardment intensity, slower deposition rate. |

| Moderate Power | Balanced ion bombardment, optimal deposition rate, manageable substrate temperatures. |

| High Power | Increased ion bombardment, higher deposition rate, potential substrate temperature issues. |

In summary, while higher sputtering power can significantly boost the deposition rate, it necessitates careful monitoring to avoid adverse effects on the substrate and the overall uniformity of the deposited film.

Gas Pressure

Gas pressure plays a pivotal role in the formation and stability of the plasma during magnetron sputtering. The pressure within the chamber directly influences the density and distribution of the plasma, which in turn affects the uniformity of the thin film deposition.

At optimal pressures, the plasma is dense enough to sustain a high rate of ion bombardment, ensuring efficient sputtering of the target material. However, if the pressure is too high, it can lead to several undesirable effects. For instance, an elevated pressure can cause the plasma to become unstable, resulting in erratic ion trajectories and uneven sputtering rates. This instability can manifest as fluctuations in the deposition rate and thickness across the substrate, leading to non-uniform film formation.

Moreover, excessive gas pressure can also increase the likelihood of collisions between sputtered atoms and gas molecules, reducing the mean free path of the sputtered particles. This reduction in mean free path can hinder the migration of atoms to the substrate, causing them to deposit in a less controlled manner. Consequently, the film's structure and properties may be compromised, with potential issues such as increased porosity or reduced adhesion.

To maintain optimal conditions, it is crucial to carefully control the gas pressure during the sputtering process. This involves selecting the appropriate gas type and flow rate, as well as implementing precise pressure control mechanisms. By doing so, one can ensure that the plasma remains stable and that the sputtered atoms deposit uniformly on the substrate, leading to high-quality thin films.

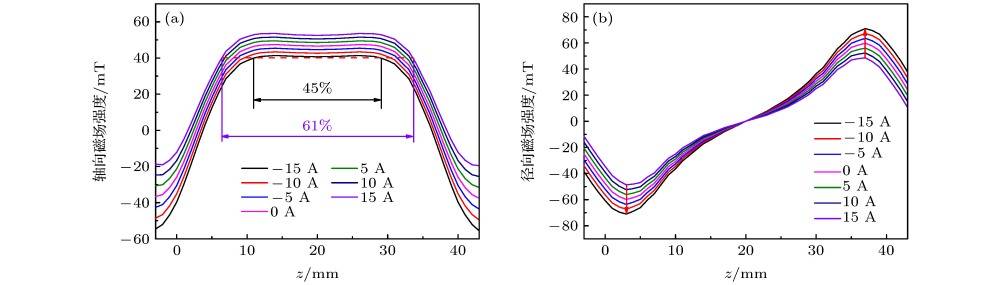

Magnetic Field Configuration

The configuration of the magnetic field plays a pivotal role in determining the properties of the plasma, which in turn significantly influences the uniformity of the sputtering process. Non-uniform magnetic fields can lead to uneven sputtering rates, resulting in variations in the thickness and quality of the deposited film. This phenomenon can be attributed to several factors:

-

Magnetic Field Strength Variation: In regions where the magnetic field is stronger, the plasma density tends to be higher. This increased plasma density enhances the ion bombardment in those areas, leading to higher sputtering rates and, consequently, thicker film deposition. Conversely, weaker magnetic field regions experience lower plasma densities and reduced sputtering rates, resulting in thinner film deposition.

-

Plasma Confinement: The magnetic field configuration also affects the confinement of the plasma. A well-designed magnetic field can confine the plasma more effectively, ensuring that the ions are directed towards the target in a more controlled manner. However, non-uniform magnetic fields can cause the plasma to escape or drift, leading to inefficient ion bombardment and uneven film deposition.

-

Target Erosion Patterns: The distribution of the magnetic field across the target surface determines the erosion patterns. In cases where the magnetic field is non-uniform, the target material erodes unevenly, with certain areas experiencing more intense erosion than others. This uneven erosion directly translates to variations in the deposition rate across the substrate.

To mitigate these issues, it is crucial to design and optimize the magnetic field configuration. This can be achieved through:

| Optimization Strategy | Description |

|---|---|

| Field Mapping | Conducting detailed mapping of the magnetic field to identify and rectify non-uniformities. |

| Field Adjustment | Fine-tuning the magnetic field strength and distribution to achieve a more uniform plasma environment. |

| Advanced Magnet Design | Employing sophisticated magnet designs, such as Halbach arrays, to create more uniform and controllable magnetic fields. |

By addressing the magnetic field configuration, it is possible to enhance the uniformity of the sputtering process, thereby improving the quality and consistency of the deposited thin films.

Substrate Properties

The shape, size, and thermal conductivity of the substrate play pivotal roles in determining the uniformity of the deposited film. These properties directly influence how the sputtered atoms migrate and adhere to the substrate surface, ultimately affecting the film's consistency across its surface.

-

Shape and Size: The geometry of the substrate can lead to variations in the film thickness. For instance, substrates with complex shapes or edges can experience non-uniform deposition rates due to the uneven distribution of sputtered atoms. This is particularly critical in applications requiring precise film thickness, such as microelectronics.

-

Thermal Conductivity: The ability of the substrate to conduct heat affects the temperature distribution during the deposition process. High thermal conductivity substrates can dissipate heat more uniformly, which helps in maintaining a stable deposition environment. Conversely, substrates with low thermal conductivity can lead to localized hot spots, causing uneven film growth and potential defects.

Understanding and optimizing these substrate properties are essential for achieving high-quality, uniform thin films in magnetron sputtering processes.

Substrate Pretreatment

Cleanliness and surface preparation are pivotal for efficient atom deposition. The substrate, which serves as the foundation for the thin film, must be free from contaminants such as oils, dust, and oxides. These impurities can disrupt the uniformity of the film, leading to defects and poor adhesion.

Surface preparation involves several critical steps:

- Cleaning Protocols: Utilizing solvents, ultrasonic baths, and plasma cleaning to remove organic and inorganic contaminants.

- Surface Roughness: Ensuring the substrate surface is neither too smooth nor too rough. Optimal roughness enhances the mechanical interlocking between the film and the substrate.

- Activation Processes: Techniques like plasma etching or ion beam bombardment can activate the substrate surface, making it more receptive to film deposition.

A well-prepared substrate not only improves film uniformity but also enhances the overall quality and performance of the deposited film.

Deposition Rate

A rapid deposition rate can lead to several detrimental effects on the quality of the thin film. One of the primary issues is the introduction of internal stresses within the film layer. These stresses can arise from the rapid accumulation of deposited atoms, which do not have sufficient time to arrange themselves in an optimal crystalline structure. As a result, the film may exhibit cracks, delamination, or other structural defects, compromising its integrity and performance.

Moreover, a high deposition rate often results in inhomogeneity in the film layer. This inhomogeneity can manifest as variations in thickness, composition, or structural properties across different regions of the film. Such inconsistencies can significantly affect the film's electrical, optical, and mechanical properties, making it unsuitable for many applications. For instance, in semiconductor manufacturing, even minor variations in film thickness can lead to substantial deviations in device performance.

To mitigate these issues, it is crucial to control the deposition rate within an optimal range. This involves balancing the need for efficient production with the requirement for high-quality film formation. Techniques such as real-time monitoring and feedback controls can help maintain a consistent deposition rate, thereby improving film uniformity and reducing internal stresses. Additionally, selecting appropriate equipment parameters, such as the target-to-substrate distance and the magnetic field configuration, can further enhance the control over the deposition process.

Temperature and Environmental Conditions

The substrate temperature plays a pivotal role in the stability and uniformity of the deposition process. Ideally, the substrate should be maintained within a specific temperature range to ensure optimal film formation. Deviations from this range can lead to issues such as increased internal stresses, altered atomic migration rates, and non-uniform film thickness.

Environmental factors, such as the operation of vacuum pumps and the composition of the gas mixture, further influence the deposition process. Vacuum pumps must operate efficiently to maintain a consistent low-pressure environment, which is crucial for stable plasma formation and atomic migration. Any fluctuations in vacuum pressure can disrupt the delicate balance required for uniform film deposition.

Gas composition is equally critical; the type and concentration of gases used in the sputtering process can significantly affect the plasma properties and the energy of the ions bombarding the target. For instance, the presence of reactive gases can modify the film's chemical composition and properties. Therefore, precise control over gas flow rates and types is essential to achieve consistent and high-quality film deposition.

In summary, maintaining an optimal substrate temperature and ensuring stable environmental conditions, including vacuum pressure and gas composition, are indispensable for achieving uniform and high-quality thin film deposition in magnetron sputtering.

Solutions and Optimization Methods

Optimize Equipment Parameters

Optimizing equipment parameters is a critical step in enhancing the uniformity of thin films deposited through magnetron sputtering. This process involves fine-tuning several key variables, including the shape and size of the target, the distance between the target and the substrate, and the sputtering power applied. Each of these parameters plays a unique role in the sputtering process, and their optimal settings can significantly influence film quality.

For instance, the shape and size of the target can impact the distribution of the sputtered atoms. A larger target can provide a more even distribution of atoms across the substrate, while a specific target shape might be designed to concentrate sputtering in certain areas to achieve desired patterns. Additionally, the distance between the target and the substrate is crucial; a shorter distance can lead to a higher density of deposited atoms, but it may also result in non-uniformity due to shadowing effects. Conversely, a longer distance can spread out the deposition more evenly but may reduce the overall deposition rate.

Sputtering power is another vital parameter that directly affects the intensity of ion bombardment. Higher power levels can increase the deposition rate, but they also risk raising the substrate temperature to levels that could cause thermal stress or even damage the substrate. Therefore, it is essential to balance the sputtering power with other parameters to maintain optimal conditions for uniform film formation.

In summary, by carefully adjusting these equipment parameters, researchers and engineers can achieve significant improvements in film uniformity, ensuring that the final product meets the required standards for various applications.

Improve Gas Flow and Pressure

Controlling the gas flow and pressure is pivotal in achieving optimal sputtering conditions, which directly influence the uniformity and quality of the deposited film. The choice of gas type and its flow rate plays a critical role in the plasma formation and the subsequent ion bombardment process. For instance, argon is commonly used due to its high ionization potential, which facilitates the creation of a stable plasma. However, the flow rate must be meticulously adjusted to ensure that the plasma remains stable without causing excessive ion scattering, which can degrade the quality of the film.

Pressure control is equally crucial, as it dictates the mean free path of the sputtered atoms. At low pressures, the atoms travel longer distances without colliding, which can lead to a more uniform deposition. Conversely, higher pressures can result in increased collisions, causing the atoms to scatter and potentially form a less uniform film. The ideal pressure range typically lies between 0.1 and 10 Pa, depending on the specific application and material being deposited.

| Parameter | Ideal Range | Impact on Film Uniformity |

|---|---|---|

| Gas Type | Argon | Stable plasma formation, efficient ion bombardment |

| Flow Rate | 10-50 sccm | Ensures stable plasma, prevents excessive ion scattering |

| Pressure | 0.1-10 Pa | Controls mean free path, influences collision frequency and film uniformity |

By carefully selecting and regulating these parameters, it is possible to maintain an optimal environment for sputtering, thereby enhancing the uniformity and overall quality of the deposited thin film.

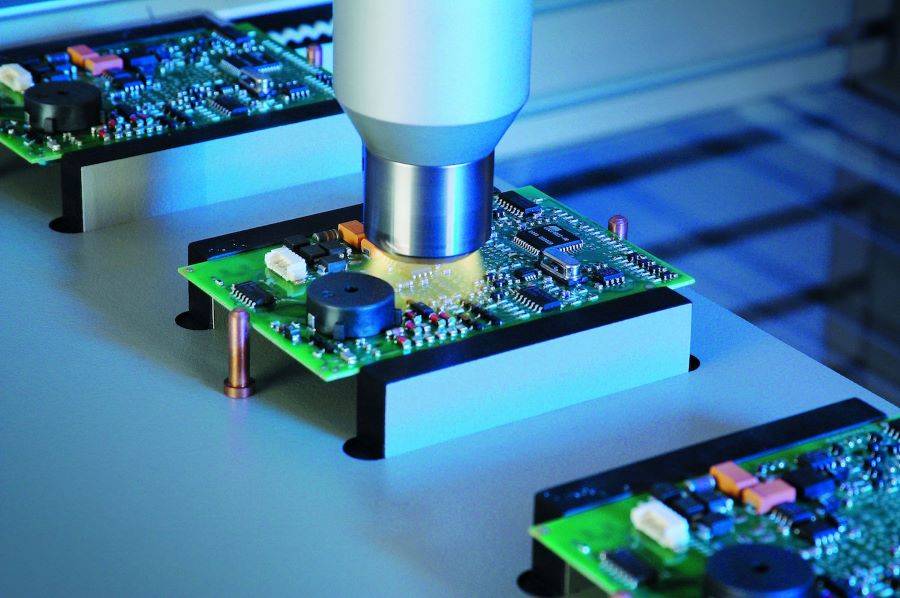

Implement Feedback Controls

Implementing feedback controls in magnetron sputtering processes is crucial for ensuring the uniformity of thin film deposition. This involves the use of advanced sensors to continuously monitor the thickness of the film as it is being deposited. These sensors provide real-time data, which is then processed by sophisticated control systems to adjust critical parameters such as sputtering power, gas pressure, and target-substrate distance.

Key Components of Feedback Controls

-

Sensors: Various types of sensors, including optical, capacitive, and eddy-current sensors, are employed to measure film thickness accurately. Optical sensors, for instance, use light reflection to gauge the film's thickness, while eddy-current sensors detect changes in electrical conductivity.

-

Control Systems: The data from these sensors is fed into control systems that use algorithms to interpret the measurements and make necessary adjustments. These systems can be as simple as PID controllers or as complex as neural networks, depending on the sophistication required.

-

Parameter Adjustments: Based on the sensor data, the control systems can dynamically adjust parameters such as sputtering power to maintain a consistent deposition rate, or gas pressure to ensure optimal plasma conditions. This real-time adjustment capability is essential for achieving uniform film thickness across the substrate.

Benefits of Feedback Controls

-

Enhanced Uniformity: By continuously monitoring and adjusting deposition parameters, feedback controls significantly improve the uniformity of the film, reducing thickness variations.

-

Process Stability: Real-time adjustments help maintain stable deposition conditions, which is crucial for high-quality film formation.

-

Reduced Waste: With precise control over the deposition process, the likelihood of producing defective films is minimized, leading to cost savings and reduced material waste.

In summary, implementing feedback controls is a vital strategy for optimizing magnetron sputtering processes, ensuring uniform film thickness, and enhancing overall film quality.

Target and Substrate Improvement

Optimizing the selection of target materials and enhancing substrate surface pretreatment are pivotal steps in achieving superior film quality. The choice of target material directly influences the chemical composition and properties of the deposited film. For instance, using high-purity targets minimizes the introduction of impurities, which can adversely affect film uniformity and performance.

Surface pretreatment of the substrate is equally critical. Proper cleaning procedures, such as chemical etching or plasma cleaning, remove contaminants and create a more reactive surface, facilitating better adhesion and smoother film growth. Techniques like ion beam etching can also be employed to modify the surface topography, further enhancing the uniformity of the deposited film.

| Aspect | Description |

|---|---|

| Target Material | High-purity targets minimize impurities; different materials offer varied film properties. |

| Substrate Cleaning | Chemical or plasma cleaning removes contaminants; ion beam etching modifies surface topography. |

In summary, meticulous selection of target materials and thorough substrate pretreatment are indispensable for achieving high-quality, uniform films in magnetron sputtering processes.

Adjust Deposition Rate

Controlling the deposition rate is a critical aspect of achieving uniform thin film deposition in magnetron sputtering processes. When the deposition rate is optimized, it significantly mitigates the risk of film stresses and inhomogeneities. A balanced deposition rate ensures that the atoms being deposited on the substrate have sufficient time to rearrange and form a cohesive structure, thereby enhancing the overall quality of the film.

To better understand the impact of deposition rate on film uniformity, consider the following factors:

- Internal Stresses: Excessive deposition rates can induce significant internal stresses within the film. These stresses can lead to cracking, delamination, or other structural defects, compromising the film's integrity.

- Inhomogeneities: Rapid deposition can result in uneven distribution of atoms across the substrate. This non-uniformity can manifest as variations in film thickness, composition, and properties, which are detrimental to the film's performance.

- Substrate Temperature: A high deposition rate often leads to elevated substrate temperatures. While some degree of heating can facilitate better film formation, excessive temperature can cause thermal stresses and affect the substrate's structural integrity.

To achieve an optimal deposition rate, it is essential to monitor and adjust several process parameters, including:

| Parameter | Impact on Deposition Rate |

|---|---|

| Sputtering Power | Higher power increases deposition rate but may cause temperature issues. |

| Gas Pressure | Appropriate pressure levels are crucial for stable atomic deposition. |

| Magnetic Field | Uniform magnetic fields promote consistent sputtering rates. |

| Substrate Properties | Proper substrate selection and pretreatment enhance film uniformity. |

By fine-tuning these parameters, operators can maintain a deposition rate that minimizes film stresses and inhomogeneities, thereby ensuring the production of high-quality, uniform thin films.

Ensure Adequate Cleaning

Pre-deposition cleaning of the substrate is a critical step that significantly impacts the adhesion and uniformity of the deposited film. The cleanliness of the substrate surface directly influences how well the sputtered atoms adhere and spread across the surface, ultimately determining the quality of the thin film.

Several methods are employed for substrate cleaning, each tailored to remove specific contaminants. For instance, chemical cleaning involves using solvents or acids to dissolve organic residues and oxide layers, while plasma cleaning utilizes a low-pressure plasma to etch the surface and remove any adsorbed gases or particles. Additionally, mechanical cleaning techniques, such as abrasive brushing or ultrasonic cleaning, can be used to physically remove particulate matter.

| Cleaning Method | Purpose |

|---|---|

| Chemical Cleaning | Dissolves organic residues and oxide layers |

| Plasma Cleaning | Etches surface to remove adsorbed gases and particles |

| Mechanical Cleaning | Physically removes particulate matter through abrasive brushing or ultrasonic waves |

Ensuring thorough cleaning not only enhances film adhesion but also promotes a more uniform distribution of deposited atoms. This uniformity is crucial for achieving consistent film properties, such as electrical conductivity and optical transparency, across the entire substrate.

In summary, the meticulous cleaning of the substrate prior to deposition is essential for optimizing the quality and performance of the thin film. It sets the stage for efficient atom deposition, ensuring that the film adheres well and exhibits the desired uniformity.

Directions for Future Research

Materials Science Research

Materials science research plays a pivotal role in advancing our understanding of how different target and substrate materials interact during the thin film deposition process. This field is crucial for identifying new factors that can significantly influence the quality and uniformity of the deposited films. By examining the atomic-level interactions between various materials, researchers can uncover novel mechanisms that affect film formation, adhesion, and overall performance.

For instance, the choice of target material can dictate the energy distribution of sputtered atoms, which in turn affects their mobility on the substrate surface. Similarly, the substrate material's properties, such as its thermal conductivity and surface roughness, can impact the nucleation and growth of the film. These interactions are not merely physical but also chemical, as the reactivity between the target and substrate materials can lead to the formation of new compounds or phases within the film.

Moreover, understanding these interactions allows for the development of tailored materials that are optimized for specific applications, whether in electronics, optics, or coatings. For example, the study of how metal targets interact with dielectric substrates can lead to the creation of high-quality, conductive films for electronic devices. Conversely, examining the behavior of ceramic targets on metallic substrates can result in the deposition of protective coatings with superior mechanical properties.

In summary, materials science research is instrumental in identifying and elucidating the complex interactions between target and substrate materials, thereby paving the way for the development of advanced thin films with enhanced properties and performance.

Advanced Monitoring Technology

Developing sophisticated monitoring systems is pivotal for achieving real-time feedback on film uniformity during magnetron sputtering processes. These advanced systems leverage cutting-edge technologies such as high-speed cameras, spectrometers, and in-situ sensors to capture minute variations in film deposition in real-time. By integrating these technologies, engineers can obtain detailed data on parameters like film thickness, surface morphology, and composition, enabling them to make immediate adjustments to maintain optimal uniformity.

For instance, high-speed cameras can capture the dynamic behavior of the plasma during sputtering, providing insights into how different regions of the target are being eroded. Spectrometers, on the other hand, can analyze the spectral lines of the sputtered atoms, offering real-time data on the composition and uniformity of the deposited film. Additionally, in-situ sensors embedded within the deposition chamber can monitor environmental conditions such as gas pressure and temperature, ensuring that these parameters remain within the optimal range for uniform film formation.

The integration of these monitoring technologies not only enhances the precision of film deposition but also allows for the implementation of adaptive control systems. These systems can automatically adjust critical parameters such as sputtering power, gas flow, and magnetic field configuration based on real-time data, thereby maintaining consistent film uniformity throughout the deposition process. This level of control is essential for applications requiring high-precision thin films, such as in the semiconductor and optical industries.

Moreover, advanced monitoring systems facilitate continuous process improvement by enabling detailed post-analysis of deposition data. This data can be used to refine simulation models and optimize future deposition runs, leading to increasingly uniform and high-quality films. As research in this field progresses, the development of even more sophisticated monitoring technologies is expected, further enhancing our ability to control and optimize thin film deposition processes.

Simulation and Computation

In the quest for achieving optimal film uniformity in magnetron sputtering, the integration of advanced computational tools has emerged as a pivotal strategy. Computer simulations and machine learning algorithms play a crucial role in this domain, offering a robust framework for optimizing the myriad parameters involved in the deposition process.

The Role of Computer Simulations

Computer simulations provide a virtual laboratory where the effects of various equipment parameters, such as target size and shape, distance between the target and substrate, and the configuration of the magnetic field, can be meticulously analyzed. These simulations allow researchers to predict the outcomes of different configurations without the need for physical experimentation, thereby saving time and resources. For instance, by modeling the trajectory of sputtered atoms and their interaction with the plasma environment, scientists can identify optimal settings that minimize film inhomogeneities.

Machine Learning for Parameter Optimization

Machine learning algorithms, particularly those employing neural networks and genetic algorithms, are increasingly being utilized to fine-tune the complex interplay of sputtering power, gas pressure, and substrate properties. These algorithms can process vast datasets from previous experiments and simulations to identify patterns and correlations that are not immediately apparent. By training on these datasets, machine learning models can suggest new parameter combinations that are likely to yield superior film uniformity.

Real-Time Feedback and Adaptive Control

One of the most promising applications of computational methods in magnetron sputtering is the implementation of real-time feedback systems. These systems use sensors to monitor key parameters during the deposition process and employ machine learning models to adjust settings dynamically. This adaptive control mechanism ensures that any deviations from the desired uniformity are promptly corrected, leading to more consistent film quality.

Future Directions

As computational power continues to advance, the scope of what can be achieved through simulation and computation in magnetron sputtering will expand. Future research may focus on developing more sophisticated models that account for the nuanced interactions between different process variables. Additionally, the integration of artificial intelligence techniques could enable the creation of self-learning systems that continuously improve their optimization strategies over time.

In summary, the marriage of computer simulations and machine learning with magnetron sputtering technology offers a powerful avenue for enhancing film uniformity. By leveraging these computational tools, researchers can push the boundaries of what is possible in thin film deposition, paving the way for more efficient and reliable manufacturing processes.

Innovative Process Technologies

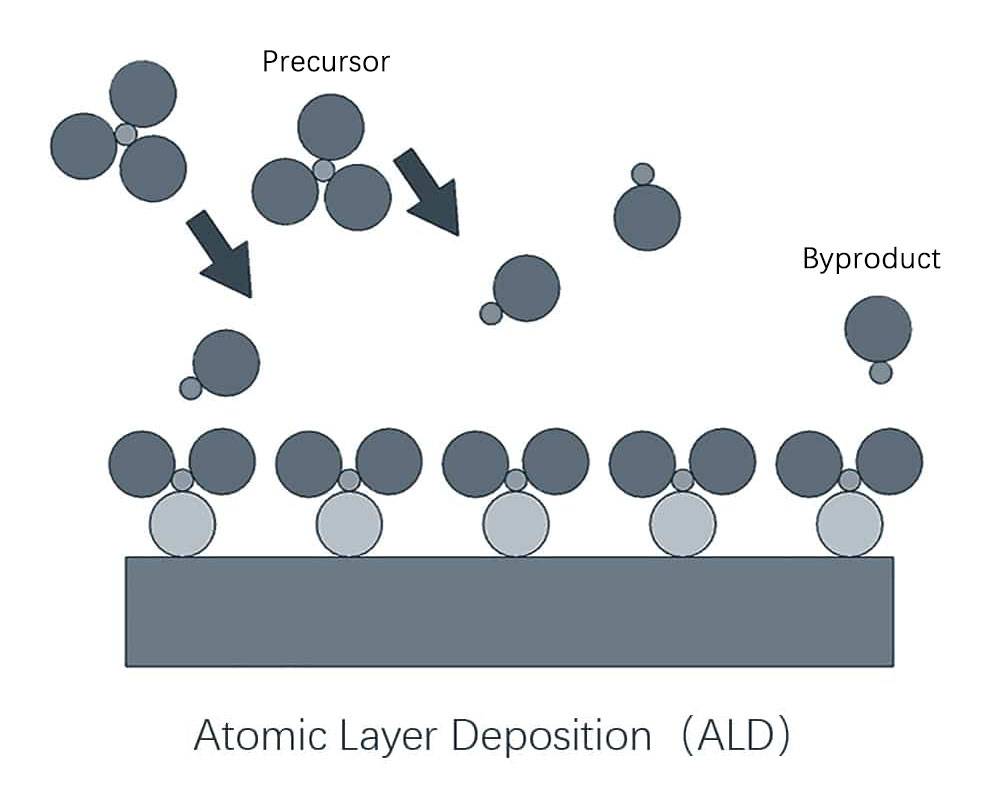

The quest for superior thin film preparation techniques has driven researchers to innovate by combining multiple deposition technologies. This multidisciplinary approach leverages the strengths of various methods to overcome individual limitations, thereby enhancing the overall efficiency and quality of film deposition.

One promising avenue is the integration of magnetron sputtering with chemical vapor deposition (CVD). This hybrid method allows for the controlled layering of materials, where sputtering provides a dense, uniform base layer, and CVD facilitates the deposition of more complex, multi-component films. The synergy between these techniques can lead to films with superior mechanical, electrical, and optical properties.

Another innovative approach involves the use of plasma-enhanced physical vapor deposition (PE-PVD). By combining plasma activation with traditional PVD methods, researchers can achieve higher deposition rates and better control over film morphology. The plasma environment not only enhances the energy of the depositing species but also allows for the incorporation of reactive gases, enabling the creation of advanced functional coatings.

Furthermore, the advent of dual-ion beam sputtering (DIBS) represents a significant leap forward. This technique employs two ion beams to simultaneously bombard the target and the substrate, allowing for precise control over the energy and angle of deposition. The result is a film with exceptional uniformity and adhesion, making it suitable for high-precision applications such as microelectronics and optical coatings.

In summary, the integration of diverse deposition technologies is paving the way for new methods of thin film preparation. These innovative processes not only address the limitations of individual techniques but also open up new possibilities for the development of advanced materials with tailored properties.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine