Introduction to Water Baths

Purpose and Applications

Constant temperature water baths are indispensable tools in various laboratory settings, serving a multitude of critical functions. These versatile devices are primarily used for distillation, drying, concentration, and constant temperature heating. The ability to maintain stable conditions is paramount in experiments, ensuring reproducible results and accurate data.

In distillation processes, water baths provide a consistent heat source, facilitating the separation of volatile components from non-volatile ones. For drying applications, they offer controlled heat to evaporate solvents without compromising the integrity of the samples. In concentration procedures, the uniform heating ensures efficient evaporation of solvents, concentrating the sample effectively. Moreover, for constant temperature heating, these baths are essential for maintaining precise temperatures required in biochemical and chemical reactions.

The importance of constant temperature water baths extends beyond these core applications. They are also used in enzyme assays, protein crystallization, and DNA amplification, where temperature stability is crucial for the success of the experiments. The ability to maintain a steady temperature within a narrow range is what makes these devices indispensable in modern laboratories.

In summary, constant temperature water baths are not just heating devices; they are precision instruments that play a vital role in ensuring the accuracy and reliability of laboratory experiments across various scientific disciplines.

Safety Considerations

Ensuring proper operation of laboratory water baths is paramount to prevent both inaccuracies in results and potential safety hazards. Improper use can lead to accidents, which can range from minor mishaps to significant incidents involving burns, electrical shocks, or equipment failure. Key safety considerations include:

- Temperature Control: Always set the temperature accurately to avoid overheating, which can damage samples or cause splashing of hot water.

- Water Level Monitoring: Maintain an appropriate water level to ensure the heating elements are always submerged, preventing dry heating that can lead to equipment damage or fires.

- Electrical Safety: Ensure the water bath is connected to a grounded power supply and avoid using it near flammable or corrosive materials to prevent electrical hazards.

- Container Selection: Use only heat-resistant containers to hold samples, reducing the risk of breakage and spillage.

By adhering to these guidelines, users can significantly reduce the risk of accidents and ensure the safe and effective operation of laboratory water baths.

Technical Details

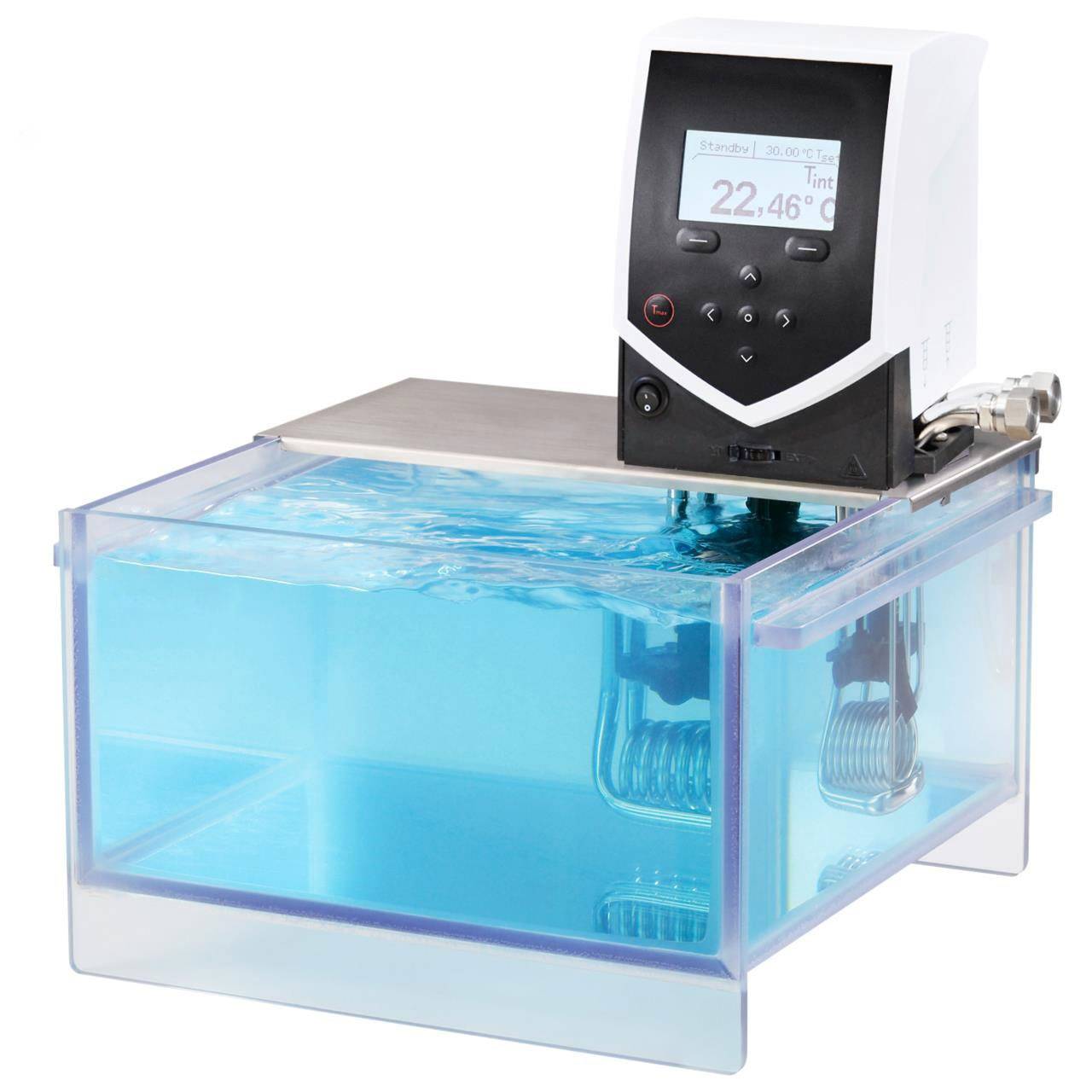

Working Principle

Water baths operate by employing sophisticated sensors to regulate the temperature with precision. These sensors continuously monitor the water temperature and adjust the heating power of the electric heating tubes accordingly. This feedback loop ensures that the temperature remains constant, making water baths particularly effective for applications requiring uniform heating below 100°C.

The core mechanism involves a thermostat that compares the actual water temperature with the setpoint. If the temperature deviates, the thermostat either increases or decreases the power supplied to the heating elements. This dynamic control system is crucial for maintaining stable conditions, which is essential for accurate and reproducible experimental results.

| Component | Function |

|---|---|

| Sensors | Monitor water temperature and relay data to the thermostat. |

| Thermostat | Compares actual temperature with setpoint and adjusts heating power. |

| Heating Tubes | Convert electrical energy into heat, controlled by the thermostat. |

This precise temperature control is particularly advantageous in laboratory settings where consistency and accuracy are paramount. Whether for distillation, drying, concentration, or maintaining constant temperatures, water baths provide a reliable solution for a variety of scientific needs.

Types of Water Baths

Water baths are available in various configurations designed to meet different experimental needs. One notable feature is the number of heating 'holes' or wells, which can range from four-hole to six-hole models. These multiple wells allow for the simultaneous heating of multiple samples, enhancing efficiency in laboratory settings.

For applications requiring precise temperature control, circulating water baths are the preferred choice. These baths ensure temperature uniformity by thoroughly circulating water throughout the bath, making them ideal for sensitive experiments such as enzymatic and serologic studies. A water bath circulator is often used in such setups to maintain consistent temperature distribution.

In contrast, non-circulating water baths rely more on natural convection for heat distribution, which can result in less accurate temperature control. However, these baths can be augmented with stirring mechanisms to improve heat transfer and achieve more uniform heating.

| Type of Water Bath | Key Feature | Ideal Applications |

|---|---|---|

| Circulating Water Baths | Thorough water circulation for uniform heating | Enzymatic, serologic, and other precision experiments |

| Non-circulating Water Baths | Convection-based heating with optional stirring | General heating needs, less critical applications |

Water baths are indispensable in various fields, including industrial clinical laboratories, academic research, government facilities, environmental studies, food technology, and wastewater treatment. Their ability to retain heat efficiently makes them one of the earliest and most reliable tools for incubation and temperature-controlled processes.

Operational Instructions

Setup and Initial Use

Before initiating the operation of your laboratory water bath, it is crucial to ensure that the device is properly set up. Begin by filling the bath with water, ensuring that the water level completely covers the heating elements. This step is vital as it prevents the heating elements from overheating and ensures uniform heating throughout the bath.

Once the water is added, power on the device. The control panel will typically display the current temperature, allowing you to set the desired temperature for your experiment. It is advisable to set the temperature slightly higher than the target temperature to account for any initial fluctuations. Allow the water bath to operate until the temperature stabilizes, which is usually indicated by a steady reading on the control panel.

During this initial phase, it is essential to monitor the water bath closely. Ensure that the temperature setting is accurate and that the device is functioning as expected. If you notice any unusual behavior, such as erratic temperature readings or failure to heat, it is best to troubleshoot the issue before proceeding with your experiment.

In summary, the setup and initial use of a laboratory water bath involve careful preparation and monitoring to ensure optimal performance. By following these steps, you can guarantee that your water bath is ready for precise and reliable temperature control, essential for various laboratory applications.

Heating Applications

The water bath is a versatile tool in the laboratory, primarily used for sample heating, reaction control, and sample dissolution. These applications require precise temperature control to ensure the integrity and accuracy of experimental results. When using the water bath for these purposes, it is crucial to place the samples in heat-resistant containers. These containers are designed to withstand the thermal conditions of the water bath, preventing any potential mishaps or contamination.

For sample heating, the water bath provides a consistent and uniform heat source, which is essential for processes that require steady temperature elevation. This method is particularly useful for delicate materials that could be damaged by rapid or uneven heating. Similarly, in reaction control, the water bath's ability to maintain a constant temperature is invaluable for reactions that are sensitive to temperature fluctuations. This ensures that the reaction proceeds at the optimal rate and produces the desired outcome.

In sample dissolution, the water bath aids in the efficient breakdown of solids into their constituent parts by providing a controlled heat environment. This process is often critical in preparing samples for further analysis, where complete dissolution is necessary for accurate results.

To summarize, the water bath's role in laboratory applications is multifaceted, offering reliable solutions for heating, reaction control, and dissolution. By using heat-resistant containers, you can maximize the efficiency and safety of these processes, ensuring that your experiments yield accurate and reproducible results.

Shutdown Procedure

After completing your experiments, it is crucial to follow a systematic shutdown procedure to ensure the longevity and safety of your laboratory water bath. Begin by powering off the device to prevent any accidental activation or overheating. Next, carefully drain all the water from the bath to avoid stagnation and potential bacterial growth. This step is particularly important as residual water can lead to corrosion and damage the internal components over time.

Once the water is drained, thoroughly clean the interior of the water bath. Use a mild, non-corrosive cleaning solution to remove any residues or scale that may have accumulated during use. Ensure that all surfaces are wiped down and dried to prevent the buildup of harmful substances that could affect future experiments.

Finally, store the equipment in a dry, well-ventilated area. This precaution helps to prevent moisture-related issues and ensures that the water bath is ready for immediate use in your next experiment. Proper storage also extends the lifespan of the equipment and maintains its operational efficiency.

By adhering to this shutdown procedure, you not only protect your laboratory water bath but also contribute to the overall safety and effectiveness of your laboratory practices.

Safety and Maintenance

General Maintenance

To ensure the longevity and optimal performance of your laboratory water bath, it is crucial to store it in a clean and dry environment. This prevents the accumulation of dust and moisture, which can compromise the device's functionality. Additionally, it is imperative to keep the water bath away from any flammable or corrosive materials. These substances can pose significant risks, including fire hazards and chemical reactions that could damage the equipment.

When it comes to powering the water bath, always use a compatible power supply. This ensures that the device receives the correct voltage and current, preventing potential electrical issues. Furthermore, it is essential to ensure that the ground wire is properly installed. A well-grounded system is a critical safety measure that helps to protect both the equipment and the users from electrical hazards.

By adhering to these maintenance practices, you can significantly extend the life of your laboratory water bath and ensure its continued reliability in various laboratory applications.

Regular Checks

Regular maintenance is crucial for ensuring the longevity and accuracy of your laboratory water bath. Begin by conducting routine inspections of the equipment to identify any signs of damage or wear. This includes checking for cracks, leaks, or any other physical anomalies that could compromise the functionality of the water bath.

Ensuring the thermostat is accurate is another critical aspect of regular checks. An inaccurate thermostat can lead to temperature fluctuations, which can affect the outcome of your experiments. Calibrate the thermostat as per the manufacturer’s guidelines to maintain precision.

Cleaning any scale buildup from the water tank is also essential. Scale can accumulate over time, especially if hard water is used, and can interfere with the heating process. Regularly descale the tank to prevent this buildup, which can reduce the efficiency of the water bath and potentially cause damage over time.

Maintaining good electrical contacts is the final step in your regular checks. Ensure that all electrical connections are secure and free from corrosion. This not only helps in preventing electrical hazards but also ensures that the water bath operates efficiently.

By adhering to these regular checks, you can ensure that your laboratory water bath remains in optimal condition, providing reliable and accurate results for your experiments.

Troubleshooting

When dealing with issues such as beeping alarms, power failures, and heating malfunctions in your laboratory water bath, a systematic approach is essential to ensure minimal disruption to your experiments.

First, check the water levels in the bath. Insufficient water can cause the heating elements to overheat and trigger alarms. Ensure the water level is maintained above the minimum required mark to prevent such issues.

Next, verify the power connections. Power failures can occur due to loose or faulty connections. Inspect the power cord and plug, ensuring they are securely connected and not damaged. If the problem persists, consider using a different power outlet to rule out any issues with the electrical supply.

If the water bath continues to malfunction, such as failing to maintain the set temperature or displaying erratic readings, it may be time to contact professional maintenance. Certified technicians can diagnose and repair more complex issues, ensuring your water bath operates efficiently and safely.

In summary, by regularly checking water levels and power connections, and knowing when to seek professional help, you can effectively troubleshoot and maintain the functionality of your laboratory water bath.

Related Products

- Laboratory Small Constant Temperature Heated Magnetic Stirrer Heater and Stirrer

- Optical Water Bath Electrolytic Electrochemical Cell

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

Related Articles

- Choosing the Right Heating Method for Laboratory Experiments

- Laboratory Heating Equipment Safety

- Choosing the Right Heating Method in Laboratory Experiments

- Preparation and Finishing Work for Using a Low-Temperature Thermostatic Reaction Bath

- Basic Constant Temperature Heating Equipment in Laboratories