Hydrolysis Methods

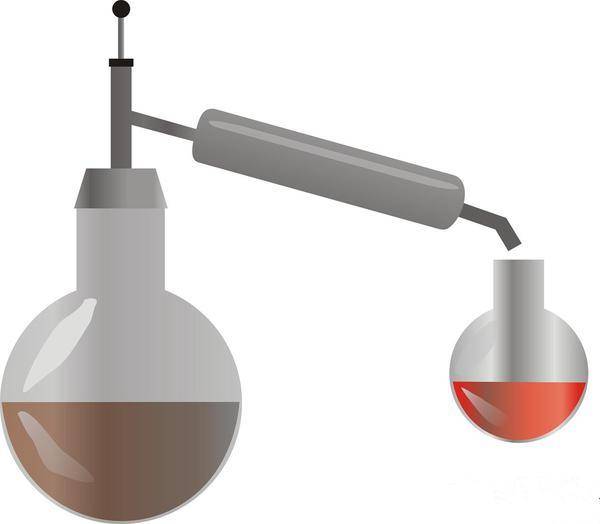

Hydrolysis of Isopropyl Alcohol Aluminum

The hydrolysis of isopropyl alcohol aluminum is a method that involves the reaction between metal aluminum and organic alcohol to form an alcohol-aluminum solution. This solution undergoes hydrolysis followed by high-temperature roasting to produce high-purity alumina products. The process is characterized by its ability to yield products with exceptionally high purity and small particle sizes, which are crucial for various industrial applications.

However, this method is not without its drawbacks. The production cost is notably high due to the complexity of the process, which includes multiple steps and stringent conditions. The intricate nature of the method also necessitates advanced control mechanisms and skilled personnel, further contributing to its elevated cost. Despite these challenges, the high-quality end products justify its use in specific high-demand industries where purity and particle size are critical.

| Advantages | Disadvantages |

|---|---|

| High purity | High production cost |

| Small particle size | Complexity |

The hydrolysis of isopropyl alcohol aluminum stands out as a method that balances the need for high-quality alumina with the inherent complexities and costs associated with its production.

Hydrolysis of High-Purity Aluminum

The hydrolysis of high-purity aluminum is a method that leverages active aluminum powder, which is prepared through the process of atomization. This powder undergoes hydrolysis in deionized water, followed by high-temperature roasting, to yield alumina products with a purity of up to 99.999%. This approach stands out for its environmental friendliness, simplicity, ease of control, and low operational costs.

The process begins with the creation of active aluminum powder through atomization, a technique that ensures the powder's reactivity and homogeneity. This powder is then subjected to hydrolysis in deionized water, a step that facilitates the breakdown of the aluminum into its constituent ions. The subsequent high-temperature roasting step is crucial for the crystallization and stabilization of the alumina, ensuring the final product's high purity and structural integrity.

One of the key advantages of this method is its green nature, as it minimizes waste and utilizes environmentally benign materials. The simplicity of the process also contributes to its ease of control, making it accessible for industrial applications. Additionally, the low cost associated with this method, coupled with its high yield of high-purity alumina, makes it an economically viable option for producers.

Compared to other hydrolysis methods, such as the hydrolysis of isopropyl alcohol aluminum, this method offers a more cost-effective solution without compromising on product quality. While the hydrolysis of isopropyl alcohol aluminum yields high-purity products with small particle sizes, it is often associated with higher production costs and complexity. In contrast, the hydrolysis of high-purity aluminum maintains high standards of purity while remaining cost-effective and straightforward.

Overall, the hydrolysis of high-purity aluminum represents a promising avenue for the production of high-purity alumina, combining environmental sustainability with economic efficiency and operational simplicity.

Pyrolysis Methods

Aluminum Ammonium Sulfate Pyrolysis

The pyrolysis of aluminum ammonium sulfate is a traditional method that involves meticulous control over synthesis conditions to yield pure ammonium aluminum sulfate. This precursor is then subjected to pyrolysis to convert it into high-purity aluminum oxide. The process is favored for its economical use of raw materials, which are both inexpensive and readily available. Additionally, the mother liquor generated during the synthesis can be recycled, further enhancing the cost-effectiveness of the method.

However, the method is not without its challenges. One of the primary issues is the calcination step, which requires precise temperature control to avoid degradation of the product. Improper calcination can lead to the formation of impurities, compromising the purity of the final aluminum oxide. Moreover, the environmental impact of this method cannot be overlooked. The pyrolysis process can release pollutants, necessitating robust environmental controls and potentially increasing the overall cost of production.

| Advantages | Challenges |

|---|---|

| Inexpensive raw materials | Precise calcination temperature control |

| Recyclable mother liquor | Potential environmental pollution |

| Cost-effective | Formation of impurities |

Despite these challenges, the aluminum ammonium sulfate pyrolysis method remains a cornerstone in the production of high-purity aluminum oxide, balancing economic considerations with the need for stringent quality control and environmental stewardship.

Ammonium Aluminum Carbonate Pyrolysis

The ammonium aluminum carbonate pyrolysis method represents a significant advancement over traditional sulfate pyrolysis techniques. This innovative approach involves the incorporation of ammonium bicarbonate (NH₄HCO₃) into the solution, which serves as a precursor for the synthesis of alumina. This addition not only enhances the efficiency of the process but also introduces notable environmental benefits.

One of the primary advantages of this method is its reduced environmental impact. By integrating NH₄HCO₃, the process effectively minimizes the generation of harmful by-products, thereby lowering the overall pollution footprint. This is particularly significant in the context of modern industrial practices, where sustainability and environmental stewardship are paramount.

However, the implementation of ammonium aluminum carbonate pyrolysis is not without its challenges. While it does mitigate environmental pollution, it introduces a new set of complexities, particularly in the treatment of waste liquids. The increased burden on waste liquid management systems necessitates advanced treatment technologies to ensure compliance with environmental regulations. This aspect highlights the need for a balanced approach that considers both the environmental and operational implications of the method.

In summary, the ammonium aluminum carbonate pyrolysis method offers a promising alternative to conventional sulfate pyrolysis by reducing environmental pollution and improving the efficiency of alumina production. Nonetheless, the associated increase in waste liquid treatment requirements underscores the importance of continuous technological advancements and strategic planning to optimize the overall process.

Modified Bayer Method

Bayer Process Improvement

The modified Bayer method represents a significant advancement over the traditional Bayer process, primarily by focusing on the meticulous control of crystallization conditions. This enhanced approach is designed to minimize the presence of impurities in the resulting aluminum hydroxide, thereby elevating the overall purity of the final alumina product. Key improvements include the optimization of desodiumization processes, which further refine the alumina, making it suitable for applications demanding high purity.

One of the standout features of this modified method is its versatility in terms of raw material sources. Unlike some other methods that may be constrained by the availability or quality of starting materials, the Bayer process improvement can accommodate a wide range of raw materials, thereby reducing costs and broadening its applicability. This adaptability not only lowers the financial burden on manufacturers but also ensures a more consistent and reliable supply chain.

Moreover, the economic benefits of this method are further underscored by its relatively lower operational costs. By streamlining the process and reducing the need for additional purification steps, the modified Bayer method offers a cost-effective solution for producing high-purity alumina. This efficiency makes it particularly attractive for industrial applications where cost-effectiveness is a critical factor.

In summary, the improved Bayer method not only enhances the purity and quality of alumina but also offers significant economic and operational advantages. Its ability to handle diverse raw materials and lower production costs positions it as a superior alternative in the quest for high-purity aluminum oxide.

Precipitation Method

Co-Precipitation, Direct Precipitation, and Uniform Precipitation

The precipitation methods, including co-precipitation, direct precipitation, and uniform precipitation, are pivotal in the synthesis of high-purity aluminum oxide. These techniques leverage non-strong alkaline compounds as precipitants, facilitating the precipitation of active ingredients from raw materials. The simplicity and ease of industrialization are notable advantages of these methods, making them suitable for large-scale production.

However, the efficacy of these methods is highly dependent on the precise control of solution composition and reaction conditions. For instance, the pH and temperature of the solution must be meticulously managed to ensure the desired precipitation of aluminum hydroxide. Any deviation from these conditions can lead to the formation of impurities or incomplete precipitation, thereby compromising the purity of the final product.

| Precipitation Method | Key Characteristics | Challenges |

|---|---|---|

| Co-Precipitation | Simultaneous precipitation of multiple components | Complexity in achieving uniform distribution |

| Direct Precipitation | Simple and straightforward | Requires precise control of conditions |

| Uniform Precipitation | Ensures homogeneous distribution of precipitants | Higher sensitivity to solution composition |

In summary, while these precipitation methods offer a straightforward approach to producing high-purity aluminum oxide, their success hinges on the meticulous control of reaction parameters. This balance between simplicity and precision is crucial for the industrial application of these techniques.

Baking Method

Sintering Temperature Control

The sintering process for preparing high-purity alumina from crude materials hinges on the precise control of temperature. This method not only ensures a convenient raw material source but also yields products of exceptional purity. However, the challenge lies in maintaining the roasting temperature within a narrow, optimal range.

To achieve this, advanced sintering furnaces equipped with high-precision PID temperature controllers play a crucial role. These controllers facilitate real-time data recording and computer communication, allowing for meticulous adjustments to the sintering chamber's temperature. The ability to operate in various atmospheres, including air, vacuum, and argon/nitrogen, further enhances the flexibility and precision of the process.

| Feature | Description |

|---|---|

| Maximum Operating Temperature | 1400°C to 1700°C |

| Chamber Customization | Tailored dimensions for specific needs |

| Temperature Control | PID controller with data recording and computer communication |

| Operational Atmosphere | Air, vacuum, argon/nitrogen |

| Heat Distribution | Advanced heating elements for even heat distribution |

| Safety Features | Automatic shut-off for safety |

| Warranty | One-year limited warranty on electronic parts |

The sintering chamber's design, featuring energy-efficient ceramic fiber insulation and a double-shell structure, ensures low outside temperatures and minimizes energy consumption. The quick heat-up and cool-down capabilities, coupled with excellent temperature accuracy and uniformity, contribute to the production of high-quality alumina products.

In summary, the precise control of sintering temperature, facilitated by state-of-the-art furnaces, is essential for the successful preparation of high-purity alumina. While the process offers significant advantages, it necessitates careful temperature management to overcome the inherent challenges.

Sol-Gel Method

Aluminum Salt and Ammonium Salt Treatment

The sol-gel method, specifically the treatment of aluminum salt and high-purity ammonia or ammonium salt solution, is a sophisticated process designed to yield high-purity alumina. This method begins with the careful synthesis of a sol-gel precursor, which is achieved by reacting aluminum salts with high-purity ammonia or ammonium salts. The resulting sol-gel is then subjected to a series of meticulous steps, including washing to remove impurities, aging to enhance structural stability, drying to remove residual moisture, and finally, roasting at elevated temperatures to crystallize the alumina.

One of the primary advantages of this method is the production of alumina with exceptionally high purity and excellent particle dispersion. The controlled chemical environment during the sol-gel formation ensures that the final product maintains a uniform particle size distribution, which is crucial for many industrial applications. However, this method is not without its drawbacks. The high cost of the raw materials, particularly the high-purity ammonia or ammonium salts, significantly increases the overall production expense. Additionally, the environmental impact of this method, particularly concerning waste disposal and chemical by-products, necessitates stringent environmental management practices.

In summary, while the aluminum salt and ammonium salt treatment method offers a pathway to high-purity alumina with desirable physical properties, it also presents challenges related to cost and environmental stewardship.

Spark Discharge Method

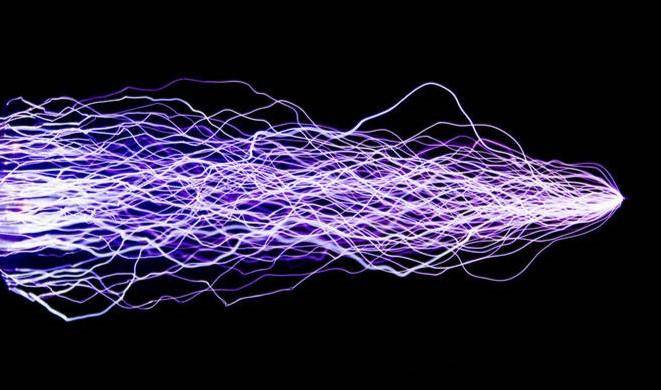

High Temperature Spark Discharge

The high temperature spark discharge method harnesses the intense heat generated by electrical sparks to facilitate the reaction between aluminum and water. This process effectively disrupts the protective alumina film that coats the aluminum surface, allowing the reaction to proceed unimpeded. The interaction between the aluminum and water results in the formation of aluminum hydroxide, or AI(OH)₃, which is then subjected to calcination to yield high-purity aluminum oxide, Al₂O₃.

This technique is particularly noteworthy for its environmental friendliness, as it minimizes the generation of harmful by-products. However, it is not without its challenges. The method is energy-intensive, requiring significant amounts of power to generate the necessary sparks. Additionally, the high temperatures involved pose safety risks, necessitating stringent safety protocols to mitigate potential hazards.

| Advantages | Challenges |

|---|---|

| Environmentally friendly | High energy consumption |

| Produces high-purity Al₂O₃ | Safety hazards |

Despite these drawbacks, the high temperature spark discharge method remains a promising avenue for the production of high-purity aluminum oxide, particularly in applications where environmental impact and product purity are paramount considerations.

Related Products

- High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

Related Articles

- Advanced Alumina Ceramics: Applications and Manufacturing Techniques

- Application of Molecular Distillation Technology in Daily-Use Chemical Industry

- Advanced Alumina Ceramics: Applications and Manufacturing Techniques

- Introduction to the Casting Process for Sputtering Targets

- Manufacturing Sputtering Targets Using Powder Metallurgy