Routine Maintenance

Initial Use and Long-Term Non-Use

When preparing a vacuum tube furnace for initial use or after extended periods of non-use, it is crucial to follow a specific heat-up procedure to prevent potential damage. Begin by heating the furnace to approximately 120 ℃ and maintain this temperature for an hour. This initial step helps to gradually warm the internal components and reduces the risk of thermal shock.

Following this, increase the temperature to around 300 ℃ and maintain it for two hours. This secondary heating phase further acclimates the furnace, particularly the heating elements and lining, to higher temperatures, thereby minimizing the likelihood of cracking or other structural damage.

It is essential to avoid exceeding the furnace's rated temperature limits at any point during this process. Exceeding these limits can lead to significant harm, such as damaging the heating elements and compromising the integrity of the furnace lining. Additionally, direct filling of liquids or metals into the furnace chamber is strictly prohibited. Such practices can cause immediate and severe damage to the internal components and should be avoided at all costs.

By adhering to these guidelines, users can ensure the longevity and optimal performance of their vacuum tube furnaces, even after long periods of inactivity.

Vacuum Maintenance

Maintaining the vacuum in a tube furnace is essential for its optimal performance and longevity. If the vacuum level diminishes, it is imperative to take immediate action to rectify the issue. One common solution is to replace the temperature-resistant silicone ring situated between the stainless steel flanges. This ring plays a crucial role in maintaining the integrity of the vacuum seal. Additionally, a thorough inspection and potential repair of the vacuum system should be conducted to ensure overall vacuum efficiency.

Key Maintenance Steps for Vacuum Systems

-

Regular Oil Checks and Changes:

- Vacuum pumps that rely on oil require meticulous maintenance. Regularly check the oil levels and condition. If the oil appears dirty or the levels are low, it is advisable to change the oil promptly. Always consult the user manual for the recommended oil type and change frequency.

-

Cleaning Pump Components:

- Over time, dust, dirt, and debris can accumulate within the pump, leading to reduced efficiency. It is essential to clean the pump head, motor, and inlet and outlet ports regularly. Use a soft brush or cloth to avoid damaging sensitive components.

-

General Maintenance Checks:

-

- Check Mounting Bolts: Ensure all mounting bolts are tight to prevent any structural instability.

- Investigate Unusual Noise or Vibration: Any unusual sounds or vibrations should be investigated promptly to avoid potential damage.

- Check Vibration Couplings: Ensure that all vibration couplings are tight and functioning correctly.

- Install Guards: Always ensure that all guards are installed before operating the pump.

- Oil Level and Contamination Check: Regularly inspect the oil levels and look for signs of contamination. Change the oil if necessary.

-

-

Roughing Pump Specific Maintenance:

-

- Check Pulleys and Belts: Ensure that pulleys and belts are properly tightened to maintain optimal performance.

- Drain Exhaust Line Filter: Drain the exhaust line filter daily and check for proper ventilation to prevent blockages.

- Clean Oil Reservoir and Valves: Clean the oil reservoir, valve deck, and solenoid valve every six months to maintain cleanliness and functionality.

-

By adhering to these maintenance practices, you can significantly enhance the lifespan and efficiency of your vacuum system, ensuring accurate and reliable performance in scientific experiments and industrial applications.

Cold Furnace Use

When operating a vacuum tube furnace in a cold state, it is crucial to adopt a gradual heating approach, particularly at low temperatures. Rapid heating can lead to thermal stress, which may result in cracks or other structural damage to the furnace components. The heating rate should be carefully controlled to ensure that the temperature increases steadily, allowing the furnace materials to acclimate to the rising heat.

Additionally, the physicochemical properties of the materials being sintered must be taken into account. Different materials have varying responses to heat, and some may release gases or undergo chemical reactions at specific temperatures. For instance, certain metals may oxidize or react with the furnace atmosphere, leading to contamination. Therefore, understanding the thermal behavior of the sintered material is essential to prevent unintended side effects.

To avoid contamination, it is advisable to preheat the furnace in stages, allowing any volatile components to dissipate before reaching critical temperatures. This approach not only protects the integrity of the furnace but also ensures the purity and quality of the sintered material. By following these guidelines, operators can maintain the longevity of their vacuum tube furnaces and achieve consistent, high-quality results in their sintering processes.

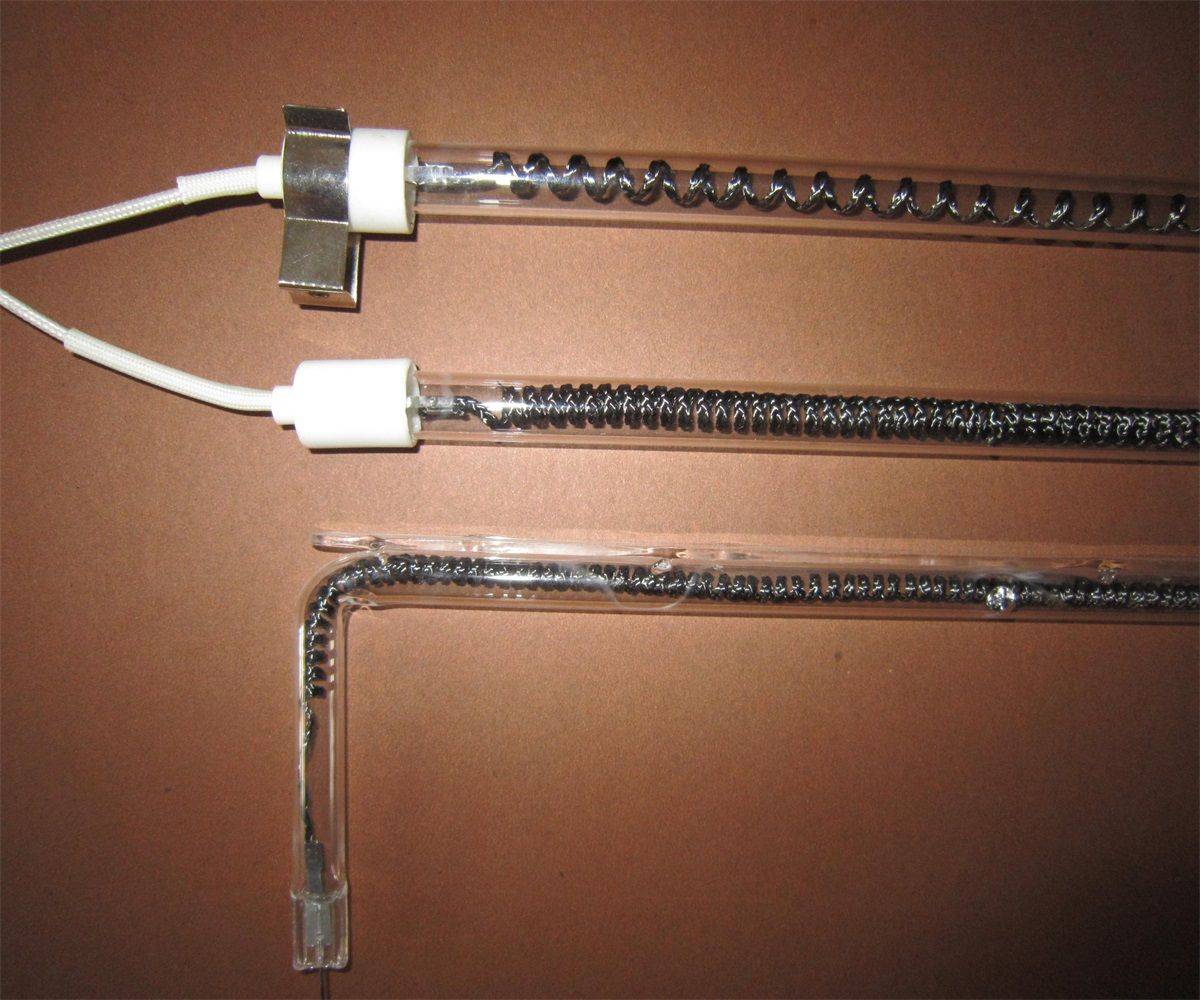

Quartz Tube Heating

At temperatures exceeding 1000℃, quartz tubes may exhibit a noticeable change in appearance, becoming increasingly opaque. This phenomenon, known as the loss of permeability, is a normal occurrence and is primarily attributed to the thermal properties of quartz. As the temperature rises, the silica structure within the quartz tube undergoes a transformation, leading to the observed opaqueness.

Understanding the behavior of quartz tubes under high temperatures is crucial for effective maintenance and optimal performance of vacuum tube furnaces. The purity of the quartz tube plays a significant role in its temperature resistance; higher purity generally correlates with greater temperature tolerance. For instance, a quartz tube with a high purity level can withstand temperatures up to 1200℃ for extended periods without significant degradation.

To ensure the longevity and efficiency of quartz tube heating elements, regular maintenance is essential. This includes careful handling to avoid physical damage and adherence to temperature limits. For example, the softening point of a typical quartz tube is around 1270℃, and it is recommended to avoid operating at 1200℃ for more than three hours to prevent structural weakening.

In practical applications, such as in the HTL1200 waffle tube furnace, specific maintenance procedures are implemented. For instance, placing alumina plugs at strategic distances (approximately 450mm apart) within the furnace can help maintain uniform heating and protect the quartz tubes from excessive thermal stress.

By following these guidelines and understanding the thermal characteristics of quartz tubes, operators can ensure a smooth and stable heating process, thereby minimizing unnecessary waste and prolonging the lifespan of their vacuum tube furnaces.

Electrical System Checks

Regular maintenance of the electrical system is crucial for the optimal performance of vacuum tube furnaces. One of the primary tasks is to regularly check the temperature control system. This involves verifying that all connections are secure and free from corrosion or wear. Ensuring that the connections are tight is particularly important for the heating elements, as loose connections can lead to inefficient heating and potential safety hazards.

In addition to checking connections, it is also essential to monitor the overall functionality of the temperature control system. This includes verifying that the system accurately reads and adjusts the temperature according to the set parameters. Any deviation from the set temperature could indicate issues with the sensors or the control circuitry, which should be addressed promptly to prevent further damage or operational inefficiencies.

Furthermore, periodic inspections of the electrical components can help identify early signs of wear or malfunction. This includes checking for any frayed wires, damaged insulation, or other signs of electrical stress. By conducting these checks regularly, you can ensure that the electrical system remains reliable and safe, thereby extending the lifespan of your vacuum tube furnace and reducing the risk of unexpected downtime.

Frequently Asked Questions

No Power Display on Meter

When the meter fails to display power, several potential issues could be at play. Common causes include an unplugged power cord, a blown fuse, or a short circuit within the control line. Each of these issues can disrupt the electrical flow necessary for the meter to function correctly.

To resolve these problems, start by inspecting the power connections. Ensure that the power cord is securely plugged in and that there are no loose connections. Next, check the fuses. If a fuse is blown, it will need to be replaced with a new one of the same rating. Finally, look for any signs of a short circuit in the control line. This might involve visually inspecting the wiring for any damage or using a multimeter to test for continuity.

By systematically addressing these potential issues, you can restore power to the meter and ensure that your vacuum tube furnace operates efficiently.

Temperature Not Rising

When the temperature in a vacuum tube furnace fails to rise as expected, several potential causes should be considered. The most common issue is a low set temperature. This can occur if the temperature control system has been inadvertently set to a lower value than required for the intended process. Adjusting the set temperature to the appropriate level can resolve this issue.

Another significant cause could be damage to the control circuit. The control circuit is integral to the operation of the furnace, and any malfunction can prevent the furnace from reaching the desired temperature. In such cases, it is crucial to notify professional maintenance personnel to diagnose and repair the control circuit. Attempting to fix the control circuit without proper expertise can lead to further damage and safety hazards.

| Possible Causes | Solutions |

|---|---|

| Low set temperature | Adjust the set temperature to the required level |

| Control circuit damage | Notify professional maintenance for repair |

Ensuring that the temperature control system is functioning correctly is essential for the efficient and safe operation of a vacuum tube furnace. Regular checks and timely maintenance can prevent such issues and extend the lifespan of the equipment.

Temperature Deviation

Temperature deviation in a vacuum tube furnace can be attributed to several factors, primarily involving the sensor or controller, or a misalignment in their positioning. When the temperature readings deviate from the expected values, it often indicates that the sensor, which measures the temperature, is malfunctioning or the controller, which regulates the temperature, is not functioning correctly. Additionally, improper alignment of these components can lead to inaccurate readings, as the sensor might not be placed optimally to capture the true temperature within the furnace.

To address these issues, the first step is to diagnose the root cause. This involves checking the sensor and controller for any visible damage or signs of wear and tear. If either component is found to be damaged, it should be replaced with a new, calibrated unit to ensure accurate temperature readings. In cases where the issue is not due to physical damage but rather misalignment, adjusting the position of the sensor or controller can rectify the problem. Proper alignment ensures that the sensor is positioned correctly to measure the temperature accurately, thereby maintaining the integrity of the heating process.

In summary, temperature deviation in vacuum tube furnaces can be resolved by replacing damaged components or adjusting their positions to ensure accurate temperature control.

No Flashing OUT Indicator

When the "OUT" indicator on your vacuum tube furnace fails to flash, it typically signals a malfunction in the main circuit. This issue can stem from several underlying causes, each requiring a specific diagnostic approach and corrective action.

Possible Causes and Solutions

| Possible Cause | Diagnostic Steps | Corrective Action |

|---|---|---|

| Main Circuit Failure | - Inspect the main circuit for any visible signs of damage or overheating. - Use a multimeter to check for continuity and resistance across the circuit. |

- If a short-circuited resistance wire is detected, isolate and replace the faulty component. - In cases where the temperature control instrument is malfunctioning, consider replacing it with a compatible, high-quality unit. |

| Loose Connections | - Examine all electrical connections, focusing on those related to the temperature control system. - Check for any signs of corrosion or wear. |

- Tighten any loose connections and replace any connectors showing signs of damage. - Ensure all wiring is securely fastened to prevent future disconnections. |

| Control Line Issues | - Inspect the control lines for any physical damage or signs of short circuits. - Test the control lines with a multimeter to verify their integrity. |

- Replace any damaged control lines to restore proper functionality. - Regularly inspect and maintain control lines to prevent future issues. |

By systematically addressing each potential cause, you can effectively troubleshoot and resolve the issue of the non-flashing "OUT" indicator, ensuring your vacuum tube furnace operates reliably and efficiently.

Thermocouple Short Circuit

When encountering a short circuit in the thermocouple of a vacuum tube furnace, immediate action is necessary to restore proper functionality. The thermocouple, a critical component responsible for accurately measuring the furnace's temperature, can malfunction due to various factors such as electrical faults or physical damage.

Solution: Replace the thermocouple. This straightforward yet essential step ensures that the furnace's temperature control system operates correctly. Before proceeding with the replacement, it is advisable to:

- Inspect the Existing Thermocouple: Check for visible signs of damage, such as cracks or burn marks, which could indicate the cause of the short circuit.

- Verify Compatibility: Ensure that the new thermocouple matches the specifications of the old one, including its material and length, to maintain the furnace's performance.

- Follow Manufacturer Guidelines: Adhere to the manufacturer's instructions for installation and calibration to avoid any discrepancies in temperature readings.

By addressing the thermocouple issue promptly, you can prevent further complications and ensure the continued reliability of your vacuum tube furnace.

Temperature Exceeding Limit

When operating a vacuum tube furnace, it is crucial to monitor the temperature closely to prevent any damage to the equipment. If the temperature exceeds the designated limit, immediate action is required to ensure the safety and longevity of the furnace.

The primary solution in such scenarios is to wait for the temperature to drop to a safe level. This allows the meter to return to normal functioning, preventing any further complications. It is important to avoid any hasty actions that might exacerbate the issue, such as abruptly turning off the power or attempting to force a temperature reduction.

To manage this situation effectively, consider the following steps:

- Monitor the Temperature: Continuously check the temperature readings to ensure it is decreasing steadily.

- Check for Blockages: Ensure there are no blockages in the cooling system that might be hindering the natural cooling process.

- Consult the Manual: Refer to the manufacturer's manual for specific guidelines on handling temperature exceedance for your model of vacuum tube furnace.

By adhering to these steps, you can safely manage the situation and prevent any long-term damage to your vacuum tube furnace.

Related Products

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Multi-zone Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

Related Articles

- Introducing the Lab Vacuum Tube Furnaces

- Installation of Tube Furnace Fitting Tee

- Vacuum Laboratory Furnaces in Advanced Materials Research

- Ultimate Guide to High Pressure Tube Furnaces: Applications, Types, and Benefits

- Infrared Heating Quantitative Flat Plate Mold: Design, Applications, and Benefits