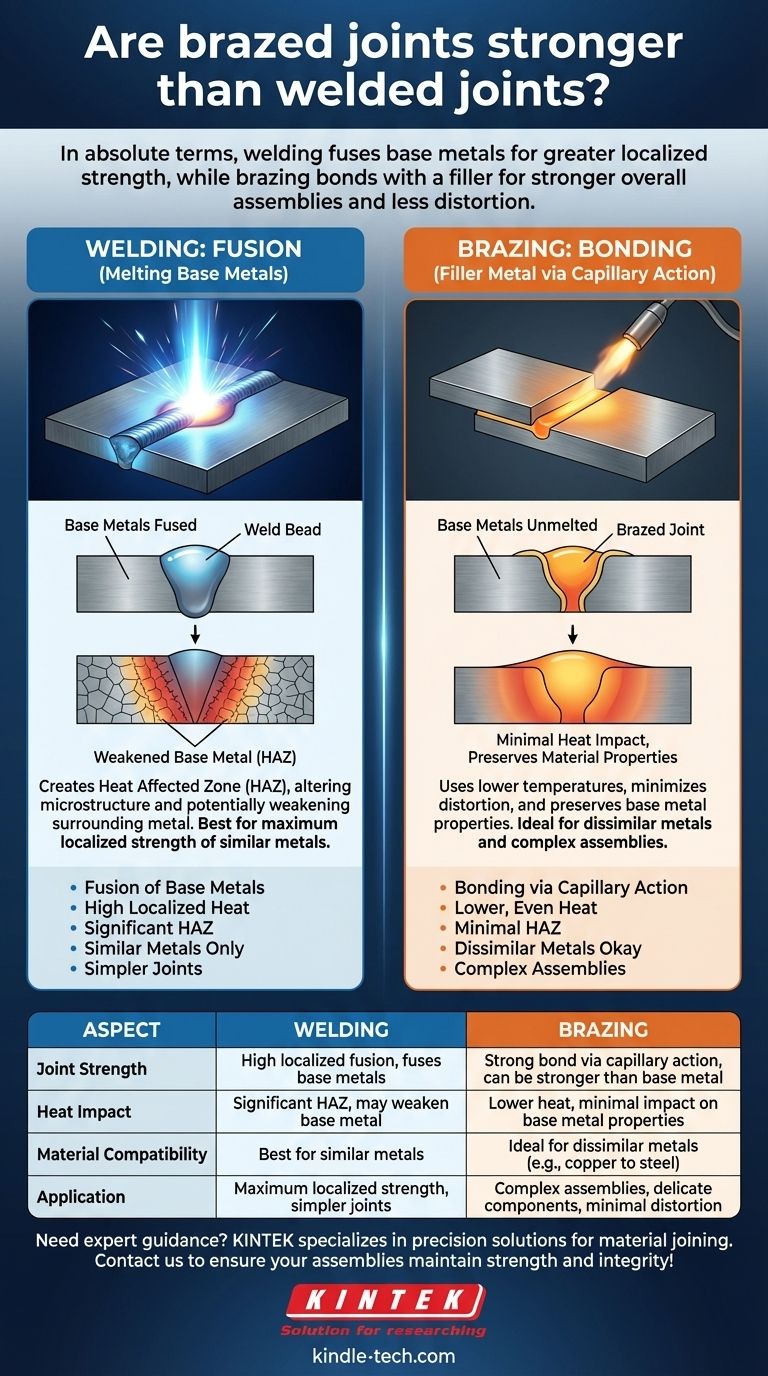

In terms of absolute joint strength, welding is typically stronger than brazing. A welded joint melts and fuses the base metals, creating a single, continuous piece, while a brazed joint uses a filler metal to bond the base metals together without melting them.

The critical distinction is not just the strength of the joint itself, but the impact of each process on the strength and integrity of the entire assembly. Choosing the right method depends entirely on the materials involved and the intended application.

The Fundamental Difference: Fusing vs. Bonding

To understand the strength comparison, you must first understand the core mechanism of each process. They are fundamentally different ways of joining metal.

How Welding Works: Fusion

Welding joins materials by melting the base metals at the joint. A filler material is often added to form a molten pool that cools to become a solid, fused joint.

This process essentially creates a single, continuous piece of metal where there were once two. The resulting joint can be as strong as, or even stronger than, the original base materials.

How Brazing Works: Bonding

Brazing joins materials by heating a filler metal above its melting point and distributing it between two or more close-fitting parts by capillary action.

The filler metal has a lower melting point than the base metals, so the base metals are never melted. The bond is formed as the filler metal wets and adheres to the surfaces of the base metals.

A Deeper Look at "Strength"

The term "strength" can be misleading. We need to differentiate between the localized strength of the joint and the overall integrity of the finished part.

Joint Strength vs. Assembly Integrity

Welding's intense, localized heat creates a Heat Affected Zone (HAZ). In this zone, the high temperature alters the microstructure and mechanical properties of the base metal, potentially weakening it even if the weld bead itself is strong.

Brazing uses significantly lower temperatures, which are distributed more evenly. This process does not melt the base metals and has a much smaller impact on their inherent properties, often resulting in a stronger, less distorted overall assembly.

The Power of Capillary Action

The strength of a brazed joint is highly dependent on the joint design. A properly designed joint has a very small, uniform gap between the parts.

The molten brazing filler is pulled into this gap by capillary action, creating a bond across a large surface area. This distribution of stress is what gives a well-designed brazed joint its exceptional strength.

"Stronger Than the Base Metal"

The reference is correct: a properly executed brazed joint can be stronger than the base materials it joins.

This means that if the part is stressed to failure, the base metal will break or tear before the brazed joint gives way. This is the benchmark for a successful joint in both welding and brazing, but brazing achieves it without weakening the surrounding material through high heat.

Understanding the Trade-offs

Neither process is universally superior. The correct choice is a matter of weighing the advantages and disadvantages for your specific application.

Key Advantages of Welding

Welding excels where the highest possible localized joint strength is the primary concern. It is often simpler for less complex joints that do not require tight tolerances.

Key Advantages of Brazing

Brazing is ideal for joining dissimilar metals (like copper to steel) and for complex or delicate assemblies where heat distortion must be minimized. The resulting joints are clean and typically require little to no finishing.

Making the Right Choice for Your Goal

To select the appropriate process, you must first define your primary objective.

- If your primary focus is maximum localized strength for similar metals: Welding is generally the more direct and effective choice.

- If your primary focus is joining dissimilar metals or delicate components: Brazing provides a strong joint without the risk of melting or distorting the base materials.

- If your primary focus is minimizing thermal distortion and post-processing: Brazing's lower heat input and clean joints make it the superior option.

- If your primary focus is creating complex assemblies with multiple joints: Brazing allows for the creation of intricate parts that would be difficult or impossible to weld.

Ultimately, the most effective joining method is the one that best preserves the material properties and dimensional accuracy of the entire assembly.

Summary Table:

| Aspect | Welding | Brazing |

|---|---|---|

| Joint Strength | High localized strength, fuses base metals | Strong bond via capillary action, can be stronger than base metal |

| Heat Impact | Creates Heat Affected Zone (HAZ), may weaken base metal | Lower heat, minimal impact on base metal properties |

| Material Compatibility | Best for similar metals | Ideal for dissimilar metals (e.g., copper to steel) |

| Application | Maximum localized strength, simpler joints | Complex assemblies, delicate components, minimal distortion |

Need expert guidance on selecting the right joining method for your lab equipment or metal components? KINTEK specializes in providing precision lab equipment and consumables, including solutions for material joining and fabrication. Our team can help you choose the optimal process—whether brazing or welding—to ensure your assemblies maintain strength, integrity, and performance. Contact us today to discuss your specific needs and enhance your project's success!

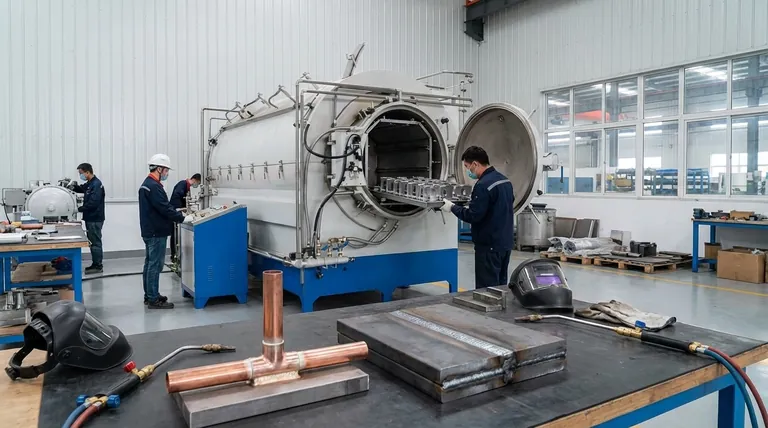

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Boron Nitride (BN) Ceramic Rod for High Temperature Applications

- Vacuum Arc Induction Melting Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

People Also Ask

- How long does a vacuum heat treatment cycle take? It Depends on Your Material and Part Size

- Why is vacuum drying equipment required for carbide production? Preserve Powder Purity & Prevent Cobalt Oxidation

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- Does nitriding affect dimensions? Yes—Here's How to Control and Predict Growth

- What is a furnace in heat treatment? The Complete Environmental Control System

- Why are vacuum furnaces required for sulfur loading on nanomaterials? Achieve uniform vapor deposition results.

- What role does a high-temperature sintering furnace play in NZSP fabrication? Key to Optimal Ionic Conductivity

- Why is a vacuum drying oven required for epoxy curing agents? Prevent Bubbles & Ensure Chemical Purity