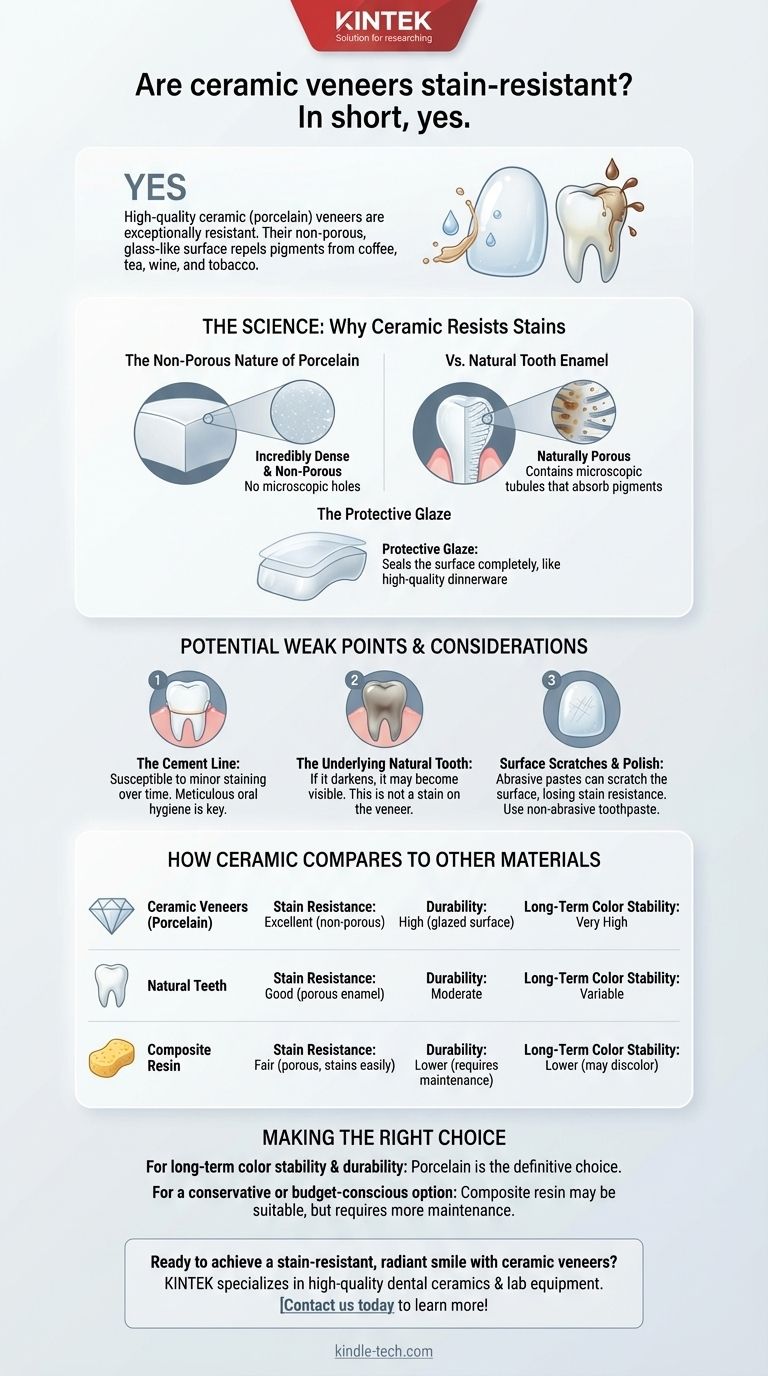

In short, yes. High-quality ceramic veneers, specifically those made of porcelain, are exceptionally resistant to staining. Their non-porous, glass-like surface does not absorb pigments from coffee, tea, red wine, or tobacco in the way that natural tooth enamel does.

While ceramic veneers themselves are highly stain-resistant, their long-term color stability depends on the integrity of the bonding agent that holds them and the health of the underlying tooth. The veneer is only one part of a complete system.

Why Ceramic Resists Stains: The Science Explained

To understand why ceramic veneers maintain their color so well, you must understand the material itself. It's a matter of basic material science.

The Non-Porous Nature of Porcelain

Dental porcelain is a type of ceramic that is fired at extremely high temperatures. This process creates a vitrified, or glass-like, surface.

This surface is incredibly dense and non-porous. Unlike a sponge, it has no microscopic holes for staining agents to penetrate.

How This Differs from Natural Tooth Enamel

Your natural tooth enamel, while the hardest substance in the human body, is naturally porous. It contains microscopic tubules that can absorb pigments over time.

This is why natural teeth gradually yellow or discolor from consistent exposure to staining foods and drinks. Ceramic does not share this vulnerability.

The Importance of the Glaze

The final step in fabricating a porcelain veneer is the application of a protective glaze. This thin, translucent layer is what gives the veneer its lifelike sheen and luster.

Crucially, this glaze seals the surface completely, making it even smoother and more impervious to staining than it already is. A properly glazed veneer is functionally equivalent to a piece of high-quality, glazed dinnerware.

Potential Weak Points and Considerations

While the ceramic material itself is a fortress against stains, there are other factors that can affect the overall appearance of your smile over time. True expertise lies in understanding these nuances.

The Weak Link: The Cement Line

Veneers are bonded to your teeth using a special dental cement. This bonding agent creates a micro-seal around the edges of the veneer.

Over many years, this thin line of cement can be susceptible to minor staining, potentially creating a very subtle dark line at the edge of the veneer, especially at the gumline. Meticulous oral hygiene is the best defense.

The Underlying Natural Tooth

A veneer is a thin shell. If the underlying natural tooth darkens significantly due to trauma, decay, or a root canal, this darker shade may become visible through the translucent ceramic.

This is not a stain on the veneer itself, but a change in the foundation that the veneer is bonded to.

Surface Scratches and Polish

A smooth, glazed veneer resists stains. However, if the surface becomes scratched or abraded by highly abrasive toothpastes or improper professional cleaning techniques, it can lose its stain resistance.

These microscopic scratches can begin to harbor pigments. It is critical to use a non-abrasive toothpaste and ensure your dental hygienist uses the correct polishing paste for porcelain.

How Ceramic Compares to Other Materials

Understanding the alternatives provides critical context for your decision.

Ceramic vs. Composite Resin

Composite resin veneers are made from a tooth-colored plastic material that is applied directly to the tooth and sculpted. While less expensive, composite is far more porous than porcelain.

Composite veneers will stain and discolor over time, much like natural teeth, and will require more frequent polishing or replacement to maintain their color.

Ceramic vs. Natural Teeth

Porcelain veneers are vastly superior to natural tooth enamel in terms of stain resistance.

They offer a way to achieve a stable, bright tooth color that is not achievable through whitening alone, especially for teeth with intrinsic (internal) staining.

Making the Right Choice for Your Goals

Your decision should be guided by your primary objective for cosmetic treatment.

- If your primary focus is long-term color stability and durability: Porcelain ceramic is the definitive choice. Its material properties provide the most predictable and stain-resistant result.

- If your primary focus is a more conservative or budget-conscious option: Composite resin may be a suitable starting point, but you must accept that it will require more maintenance and will stain over time.

Ultimately, choosing ceramic veneers is an investment in a predictable and color-stable aesthetic solution.

Summary Table:

| Feature | Ceramic Veneers | Natural Teeth | Composite Resin |

|---|---|---|---|

| Stain Resistance | Excellent (non-porous) | Good (porous enamel) | Fair (porous, stains easily) |

| Durability | High (glazed surface) | Moderate | Lower (requires maintenance) |

| Long-Term Color Stability | Very High | Variable | Lower (may discolor) |

Ready to achieve a stain-resistant, radiant smile with ceramic veneers? KINTEK specializes in high-quality dental ceramics and lab equipment, providing dental professionals with the materials needed for durable, aesthetically superior restorations. Contact us today to learn how our products can enhance your practice and patient outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia