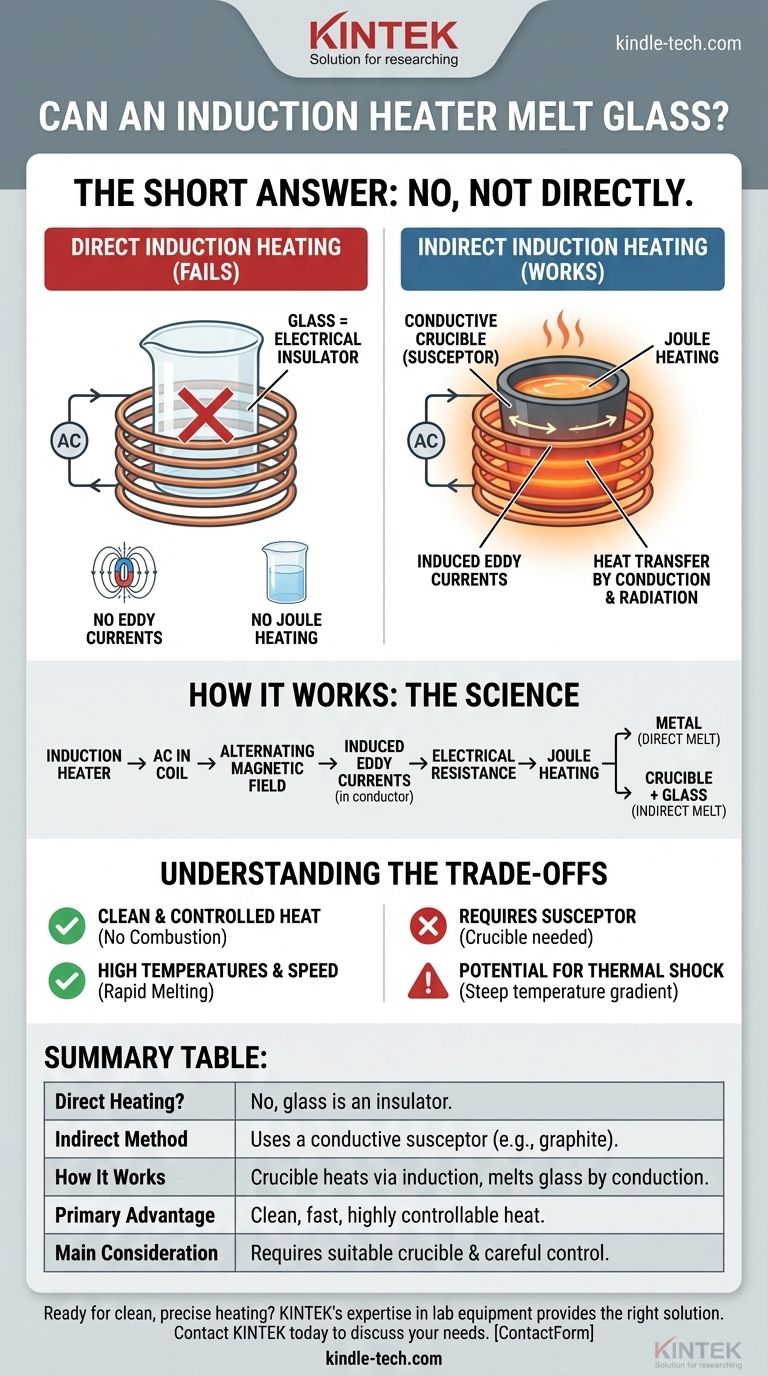

The short answer is no, an induction heater cannot melt glass directly. Standard induction heating technology relies on principles that do not work on electrically insulating materials like glass. However, it is possible to melt glass using an induction heater through an indirect method.

The core issue is that induction heating works by inducing electrical currents within a material. Since glass is an excellent electrical insulator, it cannot sustain these currents and therefore does not heat up from the magnetic field alone. The solution involves heating a conductive container, which then melts the glass inside it.

The Fundamental Principle: How Induction Heating Works

To understand why glass is unaffected, we must first understand the mechanism of induction. The process is based entirely on the principles of electromagnetism and electrical resistance.

The Alternating Magnetic Field

An induction heater uses a coil of wire through which a high-frequency alternating current (AC) is passed. This current generates a powerful and rapidly changing magnetic field in the space within and around the coil.

Inducing Eddy Currents

When an electrically conductive material, such as a piece of metal, is placed inside this magnetic field, the field induces circular electrical currents within the material. These are known as eddy currents.

Resistance Creates Heat

As these eddy currents swirl through the material, they encounter electrical resistance. This resistance converts the electrical energy into heat—a phenomenon known as Joule heating. It is this intense, localized heat that can bring metals to a molten state in seconds.

Why Glass Resists Induction

The failure of induction to heat glass is not a limitation of the heater, but a fundamental property of the glass itself.

Glass as an Electrical Insulator

Glass is a dielectric material, which means it is a very poor electrical conductor. It lacks the free-moving electrons that are abundant in metals. These free electrons are essential for forming the eddy currents described above.

No Current, No Heat

Because the magnetic field cannot induce a significant electrical current within the glass, the Joule heating effect does not occur. The energy from the magnetic field passes through the glass with virtually no effect, leaving it at room temperature.

The Solution: Indirect Induction Heating

While direct heating is impossible, you can use an induction system to melt glass by introducing an intermediary component known as a susceptor.

The Crucible Method

The most common method is to place the glass inside a container, or crucible, made from an electrically conductive material. This crucible acts as the susceptor.

Material Selection is Key

The crucible must be made of a material that is both conductive and has a much higher melting point than glass. Graphite and silicon carbide are excellent and widely used choices for this purpose.

Heat Transfer by Conduction

When the induction heater is activated, it heats the conductive graphite crucible, not the glass. The crucible heats up rapidly and then transfers its thermal energy to the glass through conduction (direct contact) and radiation, causing the glass to melt.

Understanding the Trade-offs

Using a susceptor is an effective workaround, but it's important to understand the advantages and disadvantages of this indirect method.

Advantage: Clean and Controlled Heat

Unlike a traditional furnace, induction heating is exceptionally clean, with no products of combustion that could contaminate the glass. The power can also be controlled with great precision.

Advantage: High Temperatures and Speed

Induction can heat a graphite crucible to very high temperatures much faster than many conventional heating methods, allowing for rapid melting.

Disadvantage: Requires a Susceptor

The primary limitation is the necessity of the crucible. The process is dependent on finding a suitable conductive container that can withstand the target temperatures and will not react with the molten glass.

Disadvantage: Potential for Thermal Shock

The rapid heating of the crucible can create a steep temperature gradient between the crucible wall and the glass. This can cause thermal shock, potentially cracking the glass vessel or the glass material before it melts. Careful power control is required to manage this risk.

Making the Right Choice for Your Application

Your approach depends entirely on what you are trying to achieve.

- If your primary focus is small-scale glass crafting or lab work: Using a graphite crucible within an induction heater is an efficient, clean, and highly effective method for melting glass.

- If your primary focus is large-scale industrial melting: While indirect induction is used in specialized applications, traditional gas-fired furnaces or direct electrical resistance heating are often more economical at a massive scale.

- If your primary focus is simply understanding the physics: Remember that the energy is always transferred to a conductive intermediary, making this a clever application of indirect heating.

By understanding this principle, you can effectively leverage induction technology for processes far beyond the heating of simple metals.

Summary Table:

| Key Aspect | Detail |

|---|---|

| Direct Heating? | No, glass is an electrical insulator. |

| Indirect Method | Uses a conductive susceptor (e.g., graphite crucible). |

| How It Works | The crucible heats via induction and melts the glass by conduction. |

| Primary Advantage | Clean, fast, and highly controllable heat source. |

| Main Consideration | Requires a suitable crucible and careful temperature control to avoid thermal shock. |

Ready to achieve clean, precise, and efficient heating for your lab?

Whether you're working with glass, metals, or other specialized materials, KINTEK's expertise in advanced lab equipment can provide the right solution for your application. Our team can help you select the ideal induction heating system and accessories to meet your specific research or production goals.

Contact KINTEL today to discuss how our lab equipment and consumables can enhance your processes and deliver superior results.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

People Also Ask

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys