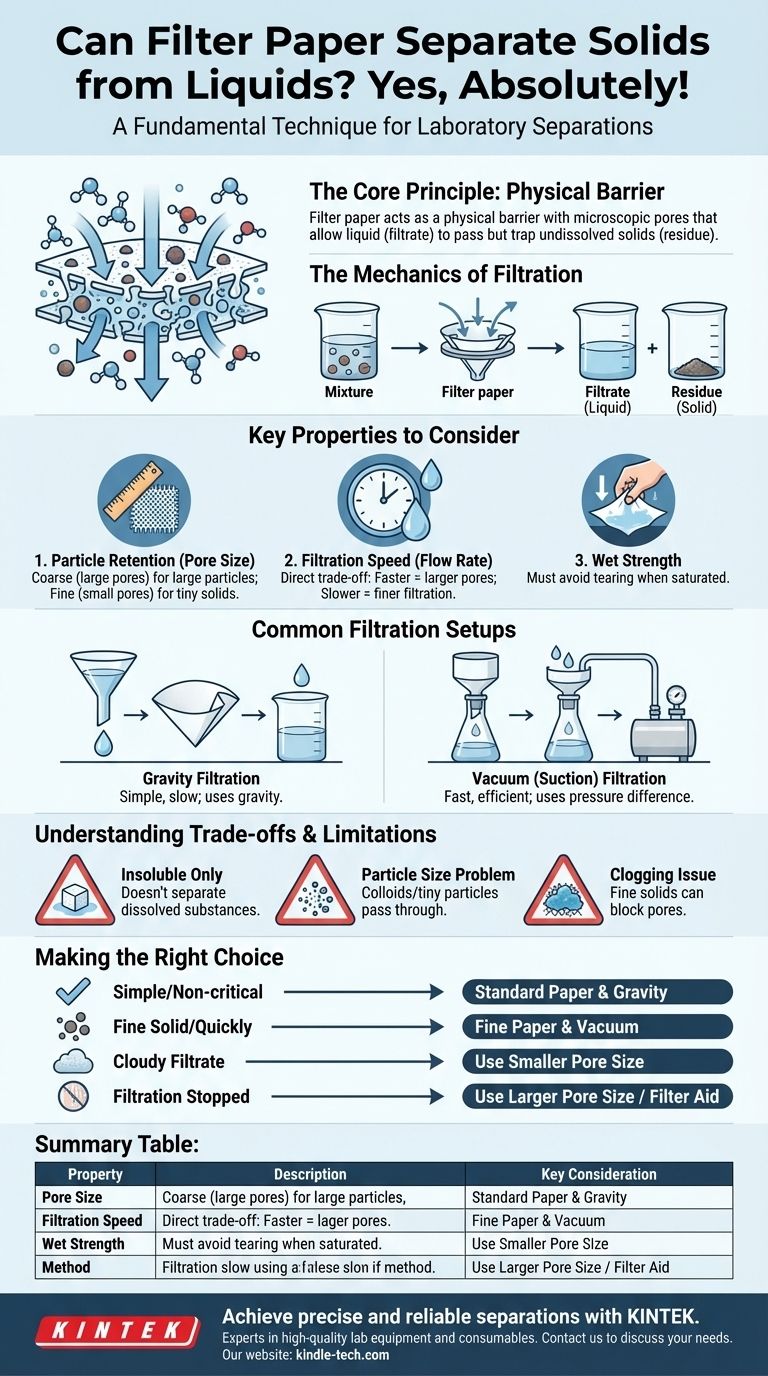

Yes, absolutely. Filter paper is specifically designed for the purpose of separating insoluble solid particles from a liquid or gas. This process, known as filtration, is a fundamental technique used in countless scientific and everyday applications, from a chemistry lab to brewing a cup of coffee.

The core principle is simple: filter paper acts as a physical barrier with microscopic pores. These pores are large enough to allow liquid molecules to pass through but small enough to trap the larger, undissolved solid particles.

The Mechanics of Filtration: How it Works

Filtration is a physical separation method, meaning it does not involve a chemical reaction. The success of the separation relies entirely on the size difference between the components of the mixture.

The Porous Medium

Filter paper is typically made from refined cellulose fibers. These fibers are processed and pressed together to form a sheet filled with a random mesh of microscopic gaps, or pores.

The Filtrate and the Residue

During filtration, two distinct components are produced. The liquid that successfully passes through the filter paper is called the filtrate. The solid particles that are caught and remain on the surface of the paper are called the residue or retentate.

The Critical Factor: Pore Size

The effectiveness of filter paper is defined by its pore size, which is the average diameter of the openings in the paper mesh. This size determines the smallest particle the paper can reliably trap.

Key Properties to Consider for Your Goal

Not all filter papers are the same. Choosing the correct one depends on the specific requirements of your mixture.

Particle Retention

This is the most crucial property, directly related to pore size and often measured in micrometers (µm).

- Coarse filters have large pores and are used for retaining large particles or gelatinous precipitates.

- Fine filters have very small pores and are necessary for capturing tiny crystalline solids.

Filtration Speed (Flow Rate)

Filtration speed refers to how quickly the liquid can pass through the paper. There is a direct trade-off between speed and particle retention.

- Faster papers have larger pores, which retain only larger particles.

- Slower papers have smaller pores, providing finer filtration but taking more time.

Wet Strength

The paper must be strong enough to hold its shape and avoid tearing when saturated with liquid and supporting the weight of the residue. This is especially important in vacuum filtration setups.

Common Filtration Setups

The method you use to perform the filtration can dramatically affect its speed and efficiency.

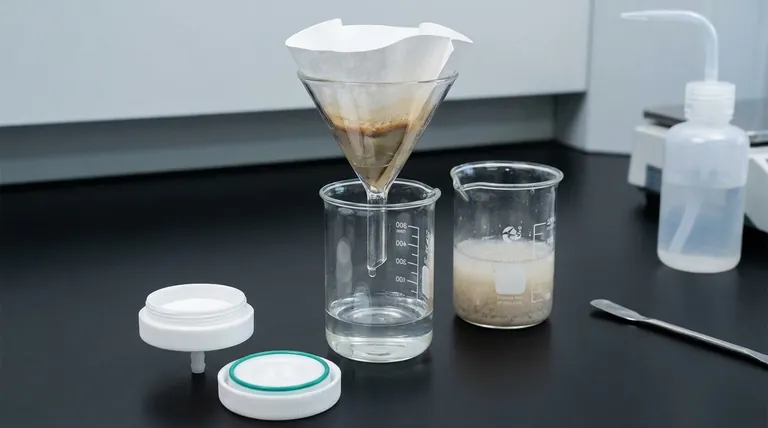

Gravity Filtration

This is the most basic setup. The filter paper is folded into a cone, placed in a funnel, and positioned over a collection vessel like a beaker or flask. The force of gravity alone pulls the liquid through the paper. This method is simple but can be slow.

Vacuum (Suction) Filtration

For a much faster separation, vacuum filtration is used. This involves a specialized flat-bottomed funnel (a Büchner funnel), a filter flask with a side-arm, and a vacuum source. The vacuum creates a pressure difference that actively pulls the liquid through the paper, drastically reducing filtration time.

Understanding the Trade-offs and Limitations

While powerful, filtration is not a universal solution for all mixtures. Understanding its limitations is key to avoiding failed experiments.

The Insoluble Requirement

Filtration can only separate insoluble solids—particles that do not dissolve in the liquid. If a solid is dissolved (e.g., salt in water), it forms a solution, and its individual ions or molecules will pass through the filter pores with the water.

The Particle Size Problem

If the solid particles are smaller than the pores in the paper, they will simply pass through with the filtrate. This is common with colloidal suspensions, where particles are too small to be trapped by standard filter paper.

The Clogging Issue

Extremely fine or gelatinous solids can quickly block the pores of the filter paper. This issue, known as clogging or blinding, can slow the filtration process to a complete halt.

Making the Right Choice for Your Task

Use your goal to determine the correct paper and method.

- If your primary focus is a simple, non-critical separation (e.g., sand from water): A standard, medium-pore-size paper and a simple gravity filtration setup are sufficient.

- If your primary focus is to collect a fine solid product quickly: Use a paper with a fine pore size rating in a vacuum filtration setup to maximize speed and product dryness.

- If your filtrate is cloudy after separation: Your solid particles are passing through the paper; you must select a filter paper with a smaller pore size.

- If your filtration has stopped completely: The paper is likely clogged; you may need to use a paper with a larger pore size or use a filter aid.

By understanding these core principles, you can confidently select the right filter paper and method to achieve a clean and effective separation.

Summary Table:

| Property | Description | Key Consideration |

|---|---|---|

| Pore Size | Average diameter of openings in the paper mesh. | Determines the smallest particle size that can be trapped. |

| Filtration Speed | How quickly liquid passes through the paper. | Faster speed = larger pores; slower speed = finer filtration. |

| Wet Strength | The paper's ability to resist tearing when wet. | Critical for supporting residue weight, especially in vacuum filtration. |

| Method | Setup used for the filtration process. | Gravity Filtration (simple, slow) vs. Vacuum Filtration (fast, efficient). |

Achieve precise and reliable separations in your lab with the right filtration equipment from KINTEK.

Whether you are purifying a chemical product, clarifying a solution, or collecting a precious solid, the correct filter paper and setup are critical for success. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of filter papers designed for various pore sizes and strengths.

Our experts can help you select the perfect filtration solution for your specific application, ensuring efficiency and accuracy in your workflow.

Contact us today via our [#ContactForm] to discuss your laboratory needs and discover how KINTEK can support your research and development goals.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Sampling Filters

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Warm Isostatic Press for Solid State Battery Research

- Lab Infrared Press Mold

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the primary function of porous PTFE sheets in Zinc-Air Fuel Cells? Optimize Your Air Cathode Performance

- Why are 0.45 μm PTFE syringe filters necessary? Protect Your LC-MS Data Integrity & Hardware

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- What is the purpose of using PTFE syringe filters in photocatalytic reactions? Ensure Precise Data & Protect Equipment

- How is plastic waste different from other types of waste? The Hidden Threat of Microplastics