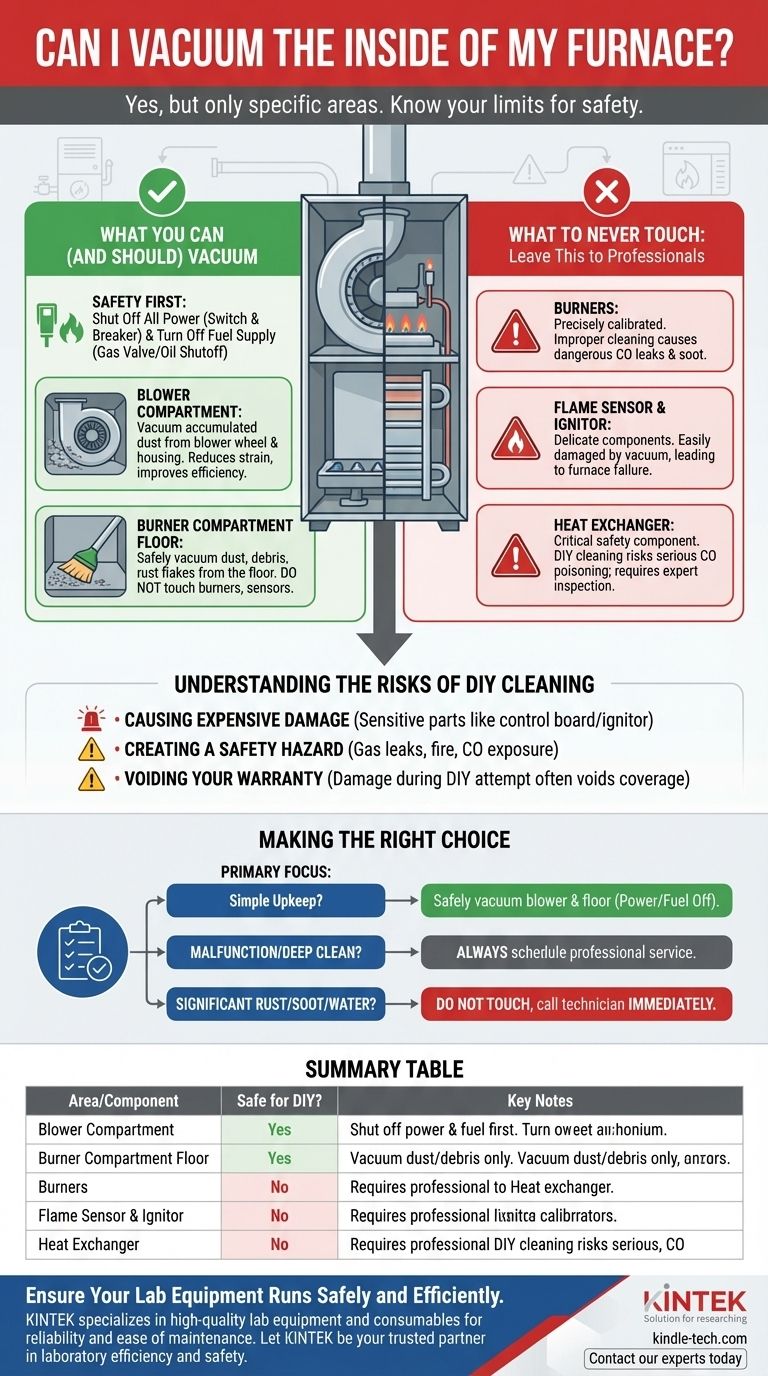

Yes, you can vacuum certain parts of your furnace, but it is critical to know which areas are safe for DIY cleaning and which must be left to a professional. For routine maintenance, a homeowner can safely vacuum dust and debris from the blower compartment and the floor of the burner compartment, provided the power and fuel supply are completely shut off first. However, sensitive components like the burners, sensors, and heat exchanger should never be touched.

The core principle of furnace maintenance is to distinguish between simple housekeeping and technical servicing. While you can safely remove accessible dust and debris, cleaning critical components requires specialized knowledge to avoid causing damage or creating a serious safety hazard.

Before You Begin: Safety First

Before opening any access panel on your furnace, you must take two non-negotiable safety steps. Failing to do so can result in serious injury or damage to the unit.

Shut Off All Power

Locate the light switch-style power cutoff on or near your furnace and turn it off. For added safety, go to your home's main electrical panel and turn off the breaker dedicated to the furnace.

Turn Off the Fuel Supply

You must also shut off the fuel. For a gas furnace, find the gas valve on the pipe leading to the unit and turn the handle so it is perpendicular to the pipe. For an oil furnace, find the oil shutoff valve (often a red handle) near the oil tank or filter and close it.

What You Can (and Should) Vacuum

With the power and fuel shut off, you can proceed with cleaning the accessible areas. Use a standard vacuum with a soft brush attachment and a long, thin crevice tool.

The Blower Compartment

The blower fan is responsible for circulating air through your home. Dust buildup on the fan blades can reduce efficiency and strain the motor. Carefully vacuum any accumulated dust from the blower wheel (the "squirrel cage") and the surrounding housing.

The Burner Compartment Floor

The compartment housing the burners often collects dust, debris, and sometimes rust flakes. You can safely vacuum the floor of this area. Be extremely careful not to touch the burners, the pilot light assembly, or the flame sensor.

What to NEVER Touch: Leave This to the Professionals

Attempting to clean the following components can easily lead to a malfunctioning or unsafe furnace. These require professional tools and training.

The Burners

The burners themselves are precisely calibrated. Bumping them or cleaning them improperly can disrupt the fuel-air mixture, leading to inefficient combustion, soot production, and the potential for dangerous carbon monoxide leaks.

The Flame Sensor and Ignitor

These components are delicate. The flame sensor is a thin metal rod that confirms a flame is present, and the ignitor is often made of brittle material. Touching them with a vacuum nozzle can misalign, damage, or break them, leading to a furnace that won't start.

The Heat Exchanger

The heat exchanger is the most critical safety component. It keeps the combustion gases separate from the air circulated in your home. You cannot see its internal surfaces, and attempting to clean it can mask or worsen cracks, which could lead to carbon monoxide poisoning. It must only be inspected and serviced by a qualified technician.

Understanding the Risks of DIY Cleaning

While light vacuuming is beneficial, overstepping your bounds carries significant risks. It's important to be aware of the potential consequences.

Causing Expensive Damage

Components like the control board, ignitor, and blower motor are sensitive. An accidental bump from a vacuum wand or static discharge can easily cause damage that requires a costly service call to fix.

Creating a Safety Hazard

The most significant risk is compromising the furnace's safe operation. Misaligning a burner, damaging a sensor, or cracking a gas line can lead to gas leaks, fire, or carbon monoxide exposure.

Voiding Your Warranty

Many manufacturer warranties stipulate that any servicing beyond changing the filter must be performed by a licensed professional. Causing damage during a DIY cleaning attempt will almost certainly void your warranty coverage for that repair.

Making the Right Choice for Your Goal

Use this guidance to decide the appropriate course of action for your furnace.

- If your primary focus is simple, routine upkeep: Safely vacuum the blower compartment and the floor of the burner area once or twice a year after shutting off all power and fuel.

- If your furnace is malfunctioning or needs a deep clean: Always schedule a professional service appointment to ensure the job is done safely and correctly.

- If you see significant rust, soot, or signs of water: Do not touch anything and call an HVAC technician immediately, as these can be signs of a serious problem.

Ultimately, knowing the limits of DIY maintenance is key to keeping your furnace running efficiently and your home safe.

Summary Table:

| Area/Component | Safe for DIY Vacuuming? | Key Notes |

|---|---|---|

| Blower Compartment | Yes | Shut off power & fuel first. Vacuum dust from blower wheel and housing. |

| Burner Compartment Floor | Yes | Shut off power & fuel first. Vacuum dust/debris only; avoid touching burners. |

| Burners | No | Requires professional. DIY cleaning can cause carbon monoxide leaks. |

| Flame Sensor & Ignitor | No | Requires professional. Delicate; easily damaged, causing furnace failure. |

| Heat Exchanger | No | Requires professional. Critical for safety; DIY risks carbon monoxide poisoning. |

Ensure Your Lab Equipment Runs Safely and Efficiently

Just like your home furnace, your laboratory equipment requires precise care to maintain performance and safety. KINTEK specializes in high-quality lab equipment and consumables, designed for reliability and ease of maintenance. Whether you need a new furnace, ovens, or other lab essentials, our products are built to meet rigorous standards.

Let KINTEK be your trusted partner in laboratory efficiency and safety.

Contact our experts today via our simple form to discuss your specific lab needs and discover how our solutions can support your work.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance