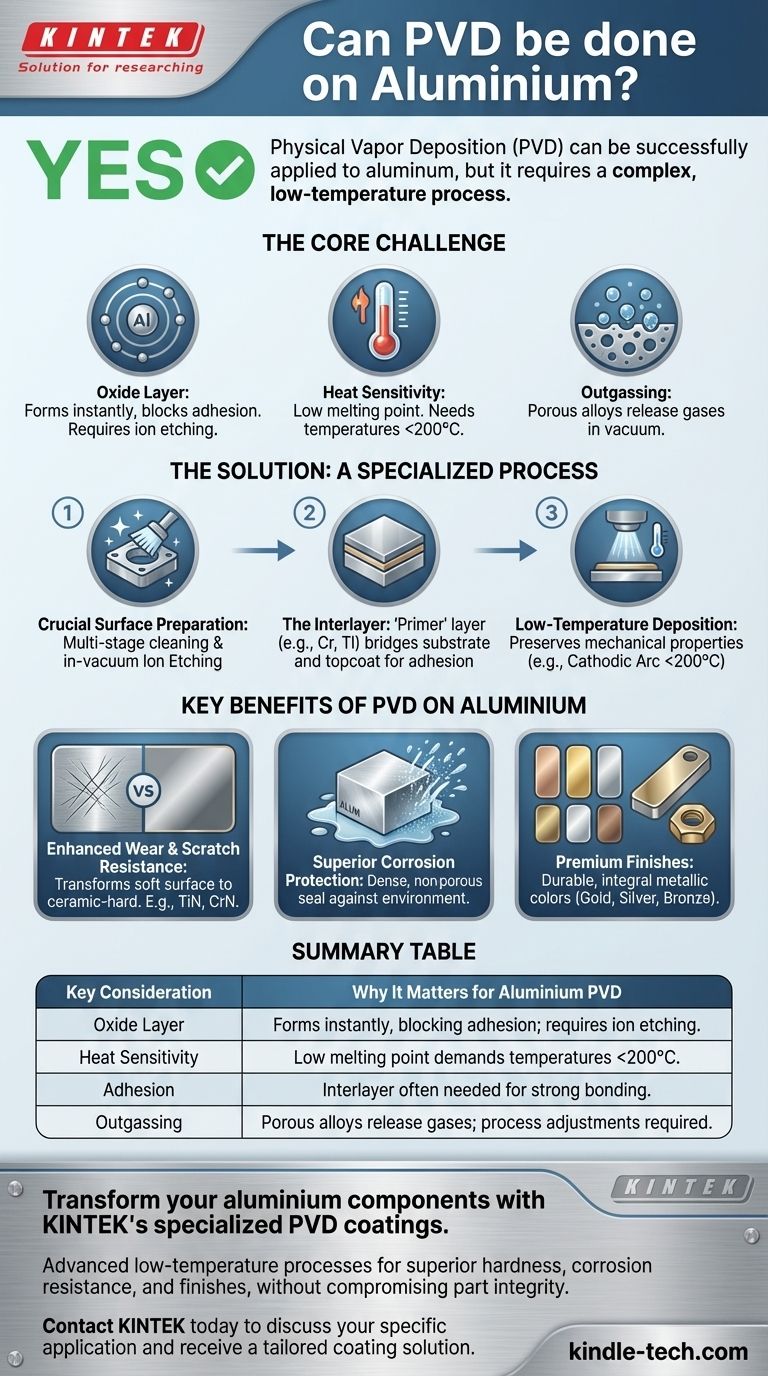

Yes, Physical Vapor Deposition (PVD) can be successfully applied to aluminum. However, it is a more complex and demanding process than coating steel or titanium. The success of the application hinges on using specialized, low-temperature techniques designed to overcome aluminum's inherent challenges, namely its low melting point and the tenacious oxide layer that forms instantly on its surface.

The core challenge of applying PVD to aluminum is not the coating itself, but preparing the aluminum to accept it. A successful outcome requires a multi-stage, low-temperature process that meticulously cleans the surface and often uses a "primer" or interlayer to ensure the final coating adheres properly without damaging the part.

Why Coating Aluminum Presents a Unique Challenge

Standard PVD processes developed for steel tooling are not suitable for aluminum. The material's fundamental properties require a completely different approach.

The Tenacious Oxide Layer

Aluminum is highly reactive with oxygen. The moment it is exposed to air, it forms a thin, hard, and transparent layer of aluminum oxide (Al₂O₃). While this layer provides natural corrosion resistance, it is a barrier that prevents the PVD coating from bonding directly to the aluminum substrate, leading to poor adhesion.

Sensitivity to Heat

Most aluminum alloys begin to soften, anneal, or lose their temper at relatively low temperatures (often between 200°C and 400°C). Traditional PVD processes can operate well above these temperatures, which would permanently weaken or even deform an aluminum part.

Outgassing and Surface Porosity

Certain aluminum alloys, particularly cast grades, can be porous. When placed in the high-vacuum environment of a PVD chamber, trapped gases can escape from the material's surface, a phenomenon known as outgassing. This can disrupt the coating deposition and create defects.

The Solution: A Specialized PVD Process for Aluminum

To overcome these obstacles, experts use a carefully controlled, multi-step process tailored specifically for temperature-sensitive substrates.

Low-Temperature Deposition

The entire process must be conducted at a temperature that preserves the mechanical properties of the aluminum alloy. Modern PVD techniques, such as cathodic arc deposition, can be operated at temperatures well below 200°C, making them safe for most common alloys.

Crucial Surface Preparation

Before the part enters the PVD chamber, it undergoes rigorous multi-stage cleaning and degreasing. Once inside, an essential in-vacuum ion etching step (also called sputter cleaning) is used. This bombards the surface with ions to remove the final layers of aluminum oxide just moments before the coating begins.

The Role of the Interlayer

In many cases, an intermediate layer is deposited directly onto the cleaned aluminum. This "primer" layer, often made of chromium, nickel, or titanium, serves several critical functions. It acts as a bridge, bonding strongly to both the aluminum substrate and the final topcoat, which dramatically improves overall adhesion.

Key Benefits of PVD on Aluminum

Despite the complexity, coating aluminum with PVD offers significant advantages that other finishes like anodizing or painting cannot match.

Enhanced Wear and Scratch Resistance

The primary benefit is a massive increase in surface hardness. A PVD coating transforms the soft surface of aluminum into a ceramic one, providing exceptional resistance to scratches, abrasion, and daily wear.

Superior Corrosion Protection

A dense, non-porous PVD coating completely seals the aluminum substrate from its environment. This offers robust protection against moisture, salt, and other corrosive agents, often outperforming standard anodizing.

A Wide Range of Premium Finishes

PVD provides a vast palette of durable, metallic colors that are integral to the surface. Popular finishes include Titanium Nitride (TiN) for gold tones, Zirconium Nitride (ZrN) for a pale gold or brass look, and Chromium Nitride (CrN) for a bright metallic silver.

Making the Right Choice for Your Application

Choosing the right PVD process for aluminum requires balancing functional needs with material limitations.

- If your primary focus is functional hardness and wear resistance: Prioritize a process that uses a proven interlayer like chromium, followed by a hard topcoat like Chromium Nitride (CrN) or Titanium Nitride (TiN).

- If your primary focus is a durable, decorative finish: Explore coatings like ZrN (gold/brass), TiCN (grey/bronze), or various proprietary multi-layer coatings that offer unique colors with excellent scratch resistance.

- If you are working with a heat-sensitive or T6-tempered alloy: Communicate the exact alloy specification to your coating provider and insist on a process that guarantees temperatures will remain below the material's critical annealing point.

By accommodating aluminum's unique characteristics, PVD transforms it into a high-performance material with both functional durability and premium aesthetics.

Summary Table:

| Key Consideration | Why It Matters for Aluminium PVD |

|---|---|

| Oxide Layer | Forms instantly, blocking adhesion; requires ion etching for removal. |

| Heat Sensitivity | Low melting point demands PVD temperatures below 200°C to avoid damage. |

| Adhesion | An interlayer (e.g., chromium, titanium) is often needed for strong bonding. |

| Outgassing | Porous alloys can release gases in vacuum, requiring process adjustments. |

Transform your aluminium components with KINTEK's specialized PVD coatings.

Our advanced, low-temperature PVD processes are engineered to overcome aluminium's unique challenges, delivering superior hardness, corrosion resistance, and a wide range of durable, decorative finishes—without compromising the integrity of your parts.

As specialists in lab equipment and consumables, KINTEK understands the precision and reliability your laboratory demands. Let us help you enhance the performance and lifespan of your aluminium instruments.

Contact KINTEK today to discuss your specific application and receive a tailored coating solution.

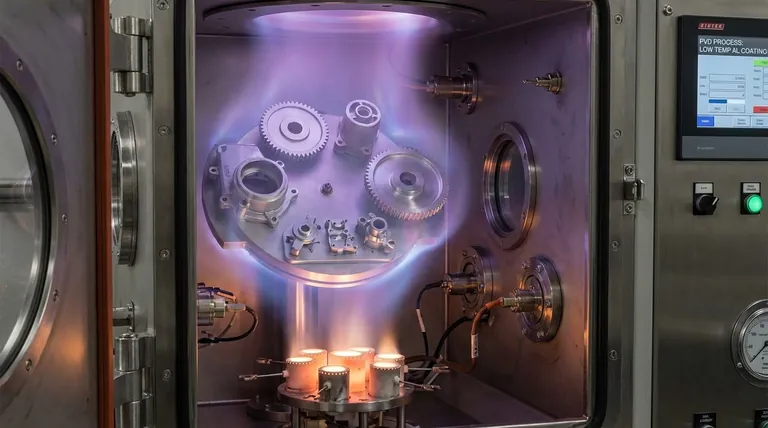

Visual Guide

Related Products

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Tungsten Evaporation Boat for Thin Film Deposition

People Also Ask

- What is evaporation material? The Key to Precision Thin-Film Deposition

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- What materials are used in thermal evaporation? From Metals to Dielectrics for Thin-Film Coating