Technically, yes, you can run a pellet stove by bypassing its vacuum switch, but doing so is extremely dangerous and fundamentally misunderstands its purpose. Bypassing this switch means you are disabling a critical safety device designed to protect you from carbon monoxide poisoning, smoke inhalation, and potential house fires. It is a modification no professional would ever recommend.

The core takeaway is this: A tripping vacuum switch is almost never the actual problem. It is a messenger, a diagnostic tool telling you that your stove lacks the proper and safe exhaust draft it needs to operate. Bypassing it is like disabling your car's oil pressure warning light instead of adding oil.

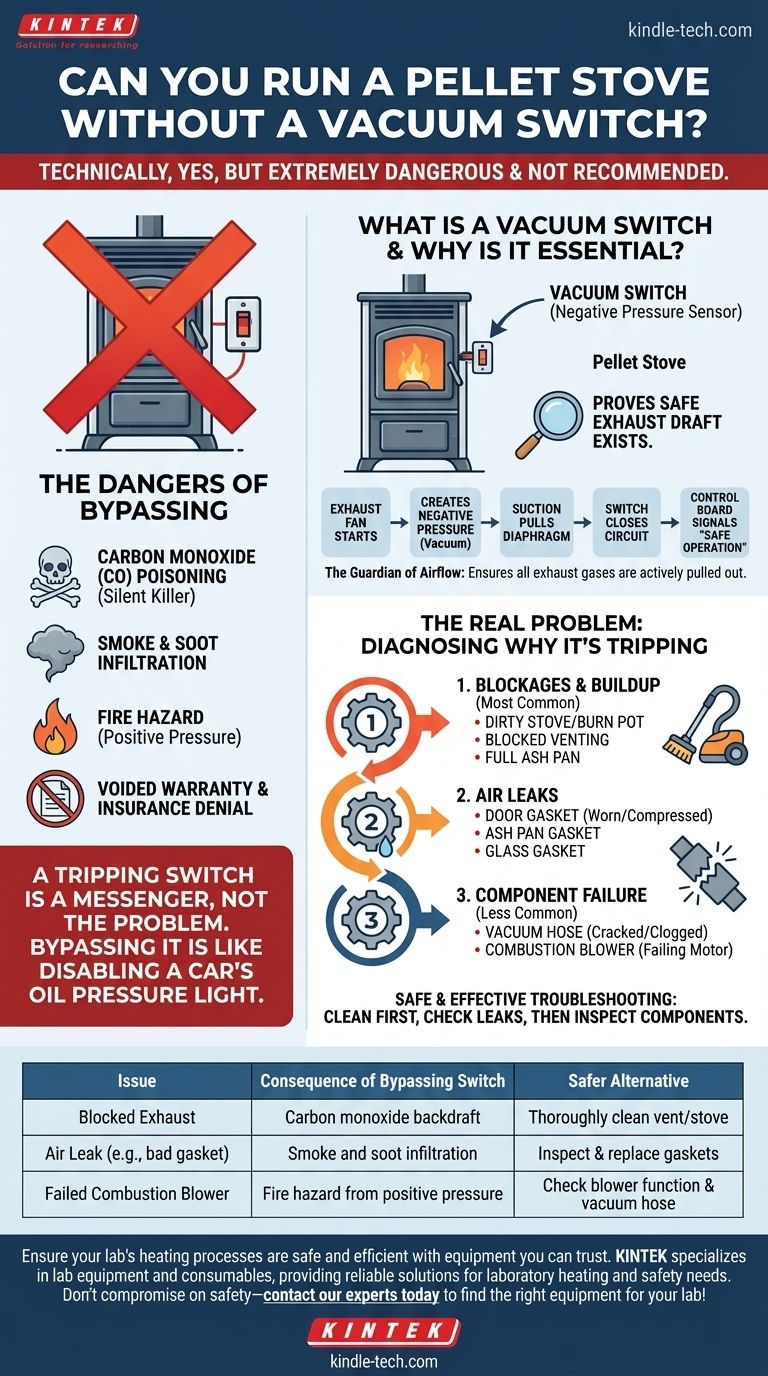

What is a Vacuum Switch and Why is it Essential?

To solve your stove's issue, you must first understand the role of the component you're tempted to remove. The vacuum switch, also called a negative pressure switch, is a non-negotiable safety feature on all modern pellet stoves.

The Guardian of Your Airflow

A pellet stove's fire must be contained within the firebox, and all exhaust gases must be actively pulled out of your home through the vent pipe. The combustion blower (exhaust fan) is responsible for creating this constant state of negative pressure, or vacuum.

The vacuum switch is a simple pressure sensor that proves this is happening. If the fan is working and the airway is clear, the switch closes, completing an electrical circuit and telling the control board, "All systems are go, the exhaust path is clear and safe for operation."

How It Works: Proving a Safe Condition

When the exhaust fan starts, it begins pulling air through the stove. This suction is channeled through a small rubber or silicone hose connected to the vacuum switch.

If the suction reaches a specific, safe level (typically a very slight pressure, around 0.05 inches of water column), it pulls on a diaphragm inside the switch, which closes the circuit. If that suction is not present, the switch remains open, and the control board will halt the startup sequence or shut down the stove.

The Critical Dangers of Bypassing the Switch

Jumping the two wires of the vacuum switch permanently tricks the control board into believing a safe draft exists, even when it doesn't. This introduces severe and potentially lethal risks.

The Silent Killer: Carbon Monoxide (CO)

This is the primary danger. If the exhaust vent is blocked (by an ash clog, a bird's nest, or soot buildup) and you have bypassed the switch, the stove will continue to run. With nowhere to go, deadly, odorless carbon monoxide gas will be forced back into your living space.

Smoke and Soot Infiltration

A less deadly but still serious result of a blocked exhaust path is smoke and soot filling your home. This can happen quickly, causing extensive property damage and respiratory irritation. The vacuum switch is your first line of defense against this.

Fire Hazard from Positive Pressure

If the exhaust is blocked, the firebox can become positively pressurized. This can push burning embers out of the stove's air intakes or any poorly sealed gaskets around the door or ash pan, creating a significant fire hazard on your floor or nearby combustible materials.

Voided Warranties and Insurance Claims

Intentionally disabling a UL-listed safety device will immediately void your manufacturer's warranty. More importantly, if a fire were to occur, your homeowner's insurance company would almost certainly deny the claim upon discovering the unauthorized and dangerous modification.

The Real Problem: Diagnosing Why the Switch is Tripping

A stove that fails to start due to the vacuum switch is operating correctly—it is protecting you from an unsafe condition. Your goal is not to defeat the switch, but to listen to its warning and find the root cause.

The Switch is a Messenger, Not the Fault

In over 95% of cases, the switch itself is perfectly fine. The problem lies in one of three areas: a blockage, an air leak, or a failed component.

Common Cause #1: Blockages and Buildup

This is the most frequent culprit. The stove cannot create a vacuum if the air cannot move freely.

- Dirty Stove: The burn pot is full, ash traps are clogged, or heat exchanger tubes are packed with soot.

- Blocked Venting: The horizontal or vertical runs of the exhaust vent are clogged with ash. The vent termination cap outside is also a common spot for blockages.

- Full Ash Pan: An overflowing ash pan can obstruct internal airflow.

Common Cause #2: Air Leaks

The stove is a sealed system. If air is getting in from somewhere other than the designated intake, a proper vacuum cannot form.

- Door Gasket: The woven rope gasket around the main door is the most common failure point. If it's worn or compressed, it won't seal properly.

- Ash Pan Gasket: A poor seal on the ash pan is another frequent source of air leaks.

- Glass Gasket: The gasket around the ceramic glass can also leak.

Common Cause #3: Component Failure

While less common, other parts can fail and lead to a lack of vacuum.

- Vacuum Hose: The small hose to the switch may be cracked, brittle, disconnected, or clogged with fine ash.

- Combustion Blower: The exhaust fan motor may be failing and not spinning fast enough to generate the required draft.

A Safe and Effective Troubleshooting Path

Instead of bypassing the switch, use it as the diagnostic tool it is. Follow this logical path to find and fix the real issue.

- If your primary focus is getting your stove running safely: Your first step is always a thorough cleaning. Perform the full cleaning procedure described in your owner's manual, paying special attention to the exhaust path, all ash traps, and the entire vent pipe from the stove to the outdoors.

- If your stove is perfectly clean but still fails to start: Your next step is to hunt for air leaks. Check the door and ash pan gaskets. A simple test is to try and close the door on a dollar bill; if you can pull the bill out easily with the door latched, your gasket is too compressed and needs to be replaced.

- If you have confirmed the stove is clean and sealed: Now you can inspect the components. Ensure the vacuum hose is clear and properly attached at both ends. Listen to the exhaust blower—does it sound weak or inconsistent? Only after checking all of these other possibilities should you consider that the vacuum switch itself might have failed.

By treating the vacuum switch as an essential diagnostic indicator, you ensure your pellet stove operates not just effectively, but with the safety your home and family deserve.

Summary Table:

| Issue | Consequence of Bypassing Switch | Safer Alternative |

|---|---|---|

| Blocked Exhaust | Carbon monoxide backdraft into home | Thoroughly clean vent pipe and stove |

| Air Leak (e.g., bad gasket) | Smoke and soot infiltration | Inspect and replace door/ash pan gaskets |

| Failed Combustion Blower | Fire hazard from positive pressure | Check blower function and vacuum hose |

Ensure your lab's heating processes are safe and efficient with equipment you can trust. KINTEK specializes in lab equipment and consumables, providing reliable solutions for laboratory heating and safety needs. Don't compromise on safety—contact our experts today to find the right equipment for your lab!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Cold Mounting Machine for Sample Preparation

- Vacuum Dental Porcelain Sintering Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

People Also Ask

- What is the purpose of using an agate mortar for LDIP processing? Master Precision in Oil-Water Separation Membranes

- What is the primary purpose of using graphite foil to wrap Tantalum Carbide samples? Ensure Pure & Precise Sintering

- What is the purpose of using a high-precision capacitance manometer to monitor pressure during cathodic cage nitriding?

- What are the uses of quartz glass? Essential for Extreme-Temperature and UV Applications

- What are the applicable sample dimensions for the sample holder? Ensure a Perfect Fit for Your Lab Samples

- What is the purpose of boron nitride spray on graphite foil in titanium hot pressing? Enhance Purity and Release

- Why are zirconia grinding balls preferred for LLZ solid-state electrolyte powders? Ensure High Purity & Performance

- How do you make quartz tubes? A Guide to High-Purity Fabrication for Demanding Applications